Choosing the right material is one of the most critical decisions in any die casting project. Among all available options, Zinc Die Casting vs Aluminum Die Casting is the most common comparison engineers, designers, and buyers face. Each material offers unique advantages, and the “better” choice depends entirely on application requirements, cost targets, and production volume.

This article provides a clear and practical comparison of Zinc Die Casting vs Aluminum Die Casting, focusing on key differences, cost considerations, and real-world applications to help you select the right solution for your project.

Introduction: Why Zinc and Aluminum Die Casting Matter

Die casting plays a vital role in modern manufacturing by enabling high-volume production of precise, durable, and complex metal components. When discussing die casting materials, Zinc Die Casting vs Aluminum Die Casting dominates the conversation because these two materials cover the widest range of industrial applications.

Understanding the differences between zinc and aluminum die casting helps manufacturers reduce costs, improve product performance, and avoid design mistakes early in the development stage. This comparison will guide you through the essential factors that influence material selection.

What Is Zinc Die Casting

Zinc die casting is a manufacturing process that uses molten zinc alloy injected into a steel mold under high pressure. Due to zinc’s low melting point, the process allows for excellent mold filling, high dimensional accuracy, and fast production cycles.

Common zinc alloys include Zamak 3, Zamak 5, and Zamak 7, which are known for their strength, ductility, and superior surface finish. Zinc die casting is especially suitable for producing complex parts with thin walls and tight tolerances.

Key Properties of Zinc Die Casting

- High strength and toughness

- Excellent dimensional stability

- Superior surface finish

- Long tooling life

- Ideal for high-volume production

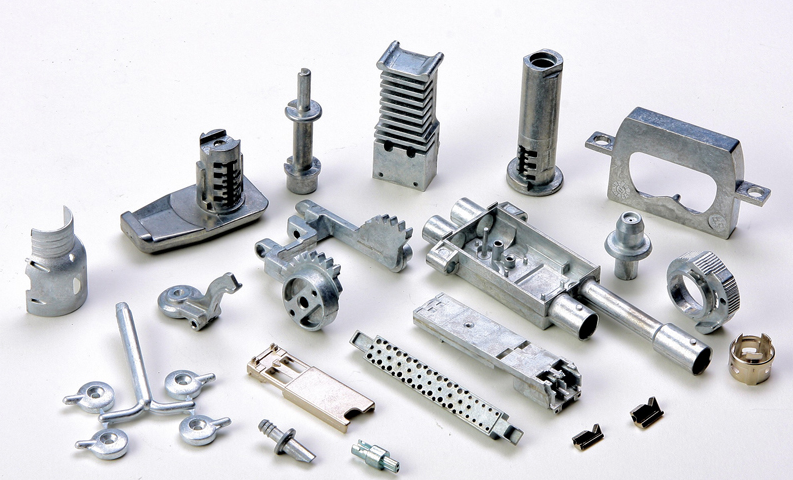

Typical Zinc Die Casting Applications

Zinc die casting is commonly used for:

- Automotive interior and functional components

- Electrical connectors and housings

- Hardware, locks, and fasteners

- Consumer electronics components

What Is Aluminum Die Casting?

Aluminum die casting involves injecting molten aluminum alloy into a mold to create lightweight yet strong metal parts. Aluminum alloys such as A380, ADC12, and A356 are widely used due to their good mechanical properties and corrosion resistance.

Aluminum die casting is especially valued for applications where weight reduction and structural strength are critical. Compared to zinc, aluminum offers a higher strength-to-weight ratio, making it suitable for larger and load-bearing components.

Key Properties of Aluminum Die Casting

- Lightweight material

- Good strength and rigidity

- Excellent corrosion resistance

- Good thermal and electrical conductivity

Typical Aluminum Die Casting Applications

Aluminum die casting is widely used in:

- Automotive structural components

- Heat sinks and electronic enclosures

- Industrial machinery parts

- Aerospace and transportation components

Key Differences Between Zinc and Aluminum Die Casting

Understanding the differences between zinc die casting vs aluminum die casting is essential for proper material selection.

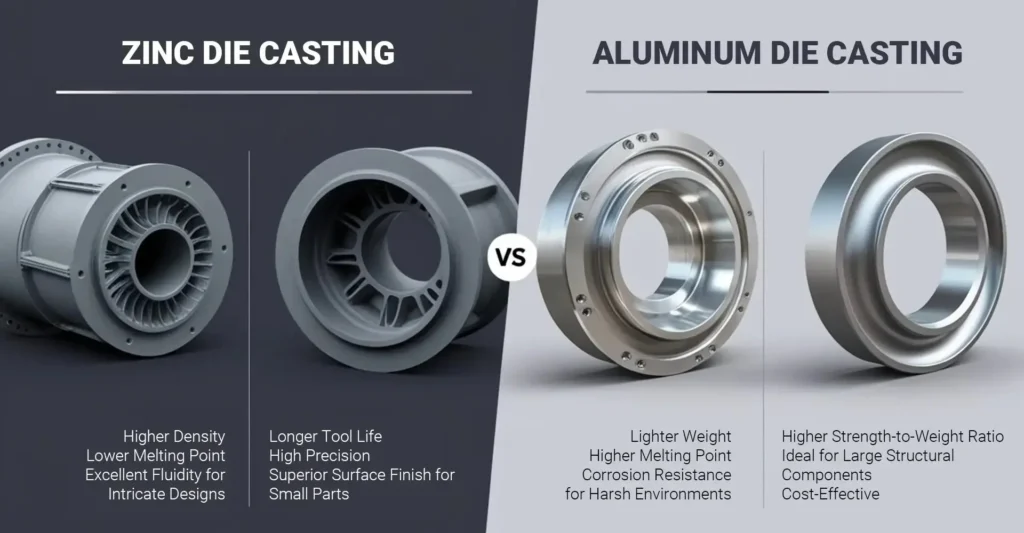

Strength and Mechanical Properties

Zinc alloys generally offer higher impact strength and better toughness, while aluminum alloys provide higher strength-to-weight performance. Zinc die casting performs well in precision components, whereas aluminum die casting excels in structural applications.

Weight and Density

Aluminum is significantly lighter than zinc. For applications where weight reduction is critical—such as automotive or transportation—aluminum die casting is often the preferred choice.

Dimensional Accuracy and Precision

Zinc die casting allows for tighter tolerances and more complex geometries. It is ideal for small, intricate parts that require minimal post-machining.

Surface Finish and Post-Processing

Zinc die casting produces a smoother as-cast surface and is highly suitable for plating, painting, and decorative finishes. Aluminum die casting may require additional surface treatment for aesthetic applications.

Tool Life and Production Efficiency

Due to zinc’s lower melting temperature, tooling experiences less thermal stress, resulting in longer mold life and faster production cycles compared to aluminum die casting.

Cost Comparison: Zinc vs Aluminum Die Casting

Cost is a critical factor when comparing zinc die casting vs aluminum die casting.

- Tooling Cost: Zinc die casting molds typically last longer, reducing long-term tooling expenses.

- Per-Part Cost: Zinc often has lower per-unit costs for high-volume production.

- Material Cost: Aluminum alloys may have higher raw material costs but offer savings through weight reduction.

- Total Cost of Ownership: Factors such as machining, finishing, and assembly should be considered, not just material price.

For complex, high-precision parts, zinc die casting is often more cost-effective. For lightweight structural components, aluminum die casting can provide better long-term value.

Applications: When to Use Zinc or Aluminum Die Casting

Automotive Components

Zinc die casting is commonly used for precision components such as brackets, housings, and interior parts. Aluminum die casting is preferred for engine components, transmission housings, and structural parts.

Electronics and Electrical Parts

Zinc die casting offers excellent EMI shielding and dimensional precision for connectors and enclosures. Aluminum die casting is widely used for heat sinks due to its thermal conductivity.

Industrial and Mechanical Equipment

Zinc is ideal for high-precision mechanical parts, while aluminum is better suited for larger, load-bearing components.

Consumer Products and Hardware

Zinc die casting is popular for decorative and functional hardware, while aluminum die casting is used for lightweight, durable consumer products.

How to Choose the Right Die Casting Material for Your Project

When deciding between zinc die casting vs aluminum die casting, consider the following:

- Required strength and durability

- Weight limitations

- Part complexity and tolerances

- Production volume

- Budget and long-term cost goals

Early collaboration with an experienced die casting manufacturer can help optimize material selection and reduce overall project costs through DFM (Design for Manufacturability) analysis.

Common Misconceptions About Zinc and Aluminum Die Casting

- “Aluminum is always stronger than zinc.”

Strength depends on alloy type and application, not just material category. - “Zinc die casting is only for small parts.”

Zinc can be used for medium-sized components with excellent performance. - “Lightweight materials always reduce cost.”

Weight reduction does not always result in lower total manufacturing cost.

Conclusion: Choosing the Right Die Casting Material

There is no universal answer to the question of zinc die casting vs aluminum die casting. Each material offers unique advantages depending on application requirements. Zinc die casting excels in precision, surface quality, and high-volume efficiency, while aluminum die casting stands out in lightweight and structural performance.

The key is selecting the material that best aligns with your design, performance, and cost objectives.

Call to Action

If you are evaluating zinc or aluminum die casting for your next project, our engineering team can help you:

- Select the optimal die casting material

- Optimize part design and cost

- Improve production efficiency

Contact us today for a free material consultation or DFM analysis, and subscribe to our podcast for more expert insights on die casting and manufacturing solutions.

IEC MOULD (China)

Location: China

Email: sherry@iec-mould.com

Tel: +86-0769-85336570

Website: www.iec-mould.com