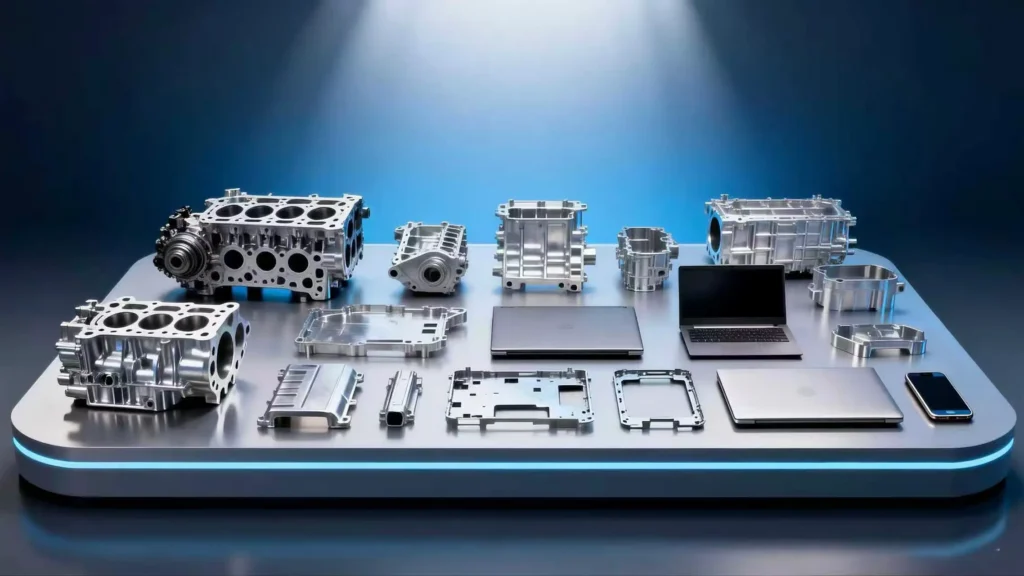

In the relentless pursuit of lightweighting, improved performance, and sustainability, magnesium die casting alloys stand out as the champions of advanced die casting. Offering the best strength-to-weight ratio of all common structural metals, magnesium is transforming industries from automotive and aerospace to consumer electronics and medical devices.

However, not all magnesium is created equal. The choice of alloy is the single most critical technical decision, directly determining a part’s performance, durability, and cost. This ultimate guide demystifies the world of magnesium die casting alloys, providing a detailed comparison of AZ, AM, AS, and WE series to empower you in selecting the optimal material for your next project.

Decoding the Nomenclature: Understanding Magnesium Alloy Codes

Before diving into specifics, understanding the standard ASTM/SAE naming system is key. A typical code like AZ91D breaks down as:

First Letters (A, M, Z, etc.): Represent the two main alloying elements in decreasing order (A=Aluminum, Z=Zinc, M=Manganese, S=Silicon, E=Rare Earths, etc.).

Numbers: Indicate the approximate percentages of the main alloying elements. In AZ91, it’s ~9% Aluminum and ~1% Zinc.

Final Letter (A, B, D, etc.): Denotes the alloy purity and variant, with later letters signifying higher purity (especially for iron and nickel), which dramatically improves corrosion resistance.

In-Depth Comparison of Major Magnesium Die Casting Alloys

Here, we dissect the properties, advantages, and ideal applications of the most widely specified magnesium die casting alloys.

AZ91D: The Industry Workhorse

AZ91D is one of the most widely used magnesium die casting alloys, renowned for its excellent combination of strength, castability, and corrosion resistance.

Key Properties: Good high yield strength, excellent corrosion resistance (due to high-purity “D” variant), and superb castability with minimal hot cracking tendency.

Strengths vs. Weaknesses: It offers the best balance of properties for general use. However, its ductility and impact toughness at room temperature are lower than the AM series.

Typical Applications: Engine brackets, transmission cases, laptop and camera housings, power tool bodies, and intricate components where thin walls and fine detail are required.

- A Successful Case: Beyond structural parts, AZ91D is also chosen for components requiring good heat dissipation. For instance, Twin City Die Casting produced an automotive audio amplifier for Bose using this alloy. This part won an award for its efficient weight saving and excellent thermal management capabilities.

AM60B & AM50A: The Ductility Champions

When impact strength and energy absorption are paramount, the AM series magnesium die casting alloys are the preferred choice.

Key Properties: Higher elongation (ductility) and superior impact resistance compared to AZ91D, alongside good strength and excellent corrosion resistance.

Strengths vs. Weaknesses: AM60B provides an optimal balance of ductility and strength. AM50A offers even higher elongation for maximum toughness. Their fluidity is slightly lower than AZ91D.

Typical Applications: Automotive safety components are the classic use case: seat frames, steering wheels, instrument panel supports, and inner door structures. Their ability to absorb energy makes them ideal for applications requiring high integrity.

- A Successful Case: Magnesium steering wheels made from AM60B have been used since 1987 by Honda and were further developed by Toyota in 1991, achieving approximately 45% weight saving compared to previous steel designs. These are now widely used across European and Asian automakers.

AS41B: The Heat-Resistant Option

For components exposed to elevated temperatures, AS41B is engineered to perform.

Key Properties: Improved creep resistance at temperatures up to ~150°C, good castability, and decent corrosion resistance.

Strengths vs. Weaknesses: It withstands sustained loads at higher temperatures better than AZ or AM alloys. Its room-temperature strength and ductility are lower.

Typical Applications: Historically used for air-cooled Volkswagen engine blocks. Today, it’s specified for engine blocks, cylinder heads, and other powertrain components exposed to moderate heat.

Creep Resistance Comparison of Die-Cast Mg Alloys at 150°C

This chart presents a qualitative comparison of the creep resistance at 150°C for three common magnesium die casting alloys, based on their compositional characteristics and performance trends reported in literature.

For specific design purposes, please refer to authoritative material handbooks or measured data.

WE43 & AE44: The High-Performance Rare Earth Alloys

Pushing the boundaries of performance, magnesium die casting alloys containing Rare Earth (RE) elements like WE (Yttrium + Rare Earths) and AE (Cerium) series offer exceptional properties.

Key Properties: Outstanding high-temperature strength, superior creep resistance (up to 300°C), excellent corrosion resistance, and good castability.

Strengths vs. Weaknesses: They represent the pinnacle of magnesium die casting alloys performance, especially for thermal and mechanical stability. The primary drawback is significantly higher material cost due to the rare earth content.

Typical Applications: Aerospace components, high-performance automotive (e.g., Formula 1, piston crowns), military applications, and anywhere extreme weight savings under high stress/heat is critical.

Magnesium Alloy Selection Guide: A Practical Decision Framework

Choosing the right magnesium die casting alloys is a systematic process. Use this flowchart as a starting point for your decision-making:

Recommended: AM60B or AM50A

High elongation & impact resistance

Recommended: AS41B or AE/WE series

For extreme temperature applications

Recommended: AZ91D

Excellent balance of properties

Important Note: This flowchart provides a simplified decision framework. The final magnesium die casting alloys selection must involve a deep discussion with your die casting partner about:

- Loading conditions - static vs dynamic, stress levels, fatigue requirements

- Secondary operations - machining, surface treatment, assembly

- Cosmetic requirements - surface finish, color, texture

- Cost targets - material cost, production efficiency, total lifecycle cost

- Regulatory compliance - industry-specific standards and certifications

Recommendation: Always consult with our engineering team for a comprehensive material analysis based on your specific application requirements.

Beyond the Alloy: The Critical Role of Integrated Die Casting Solutions

Selecting the perfect alloy is only the first step toward a flawless component. The true value of a partner lies in their ability to deliver a complete integrated die casting solution:

Precision Mold Design & Flow Simulation: Ensuring the chosen alloy fills the mold optimally for part integrity.

Advanced Process Control: Utilizing techniques such as vacuum die casting to minimize porosity, enable heat treatment and welding, and enhance mechanical properties.

Expert Secondary Operations: Precision machining, surface finishing (e.g., micro-arc oxidation for ultra-hard coatings), and assembly.

Stringent Quality Assurance: Adherence to international standards (e.g., IATF 16949 for automotive), full traceability, and comprehensive testing (X-ray, CMM).

FAQ

A: Yes. Modern high-purity alloys like AZ91D and AM60B, especially when paired with appropriate surface treatments (e.g., chrome-free conversion coating, anodizing), offer excellent corrosion resistance suitable for most automotive and industrial applications.

A: The key difference is in ductility vs. strength. AZ91D has higher yield strength (~160 MPa) and is slightly easier to cast. AM60B has significantly higher elongation (~8-10% vs. ~3% for AZ91D) and impact strength, making it tougher. The choice hinges on whether the part needs to be stiff (AZ91D) or absorb energy (AM60B).

A: While the raw material cost per kg can be higher than aluminum, magnesium's superior lightweighting and castability often lead to lower total cost-per-part. Thinner walls, faster cycle times, and reduced weight in the final product (improving fuel efficiency) contribute to significant overall system savings.

A: Absolutely. In fact, die casting is ideal for high volumes. Magnesium's excellent fluidity allows for fast cycle times and complex, thin-walled designs, making it extremely economical for large production runs in automotive and consumer electronics.

Conclusion

The path to a successful lightweight component begins with an informed choice of materials. From the versatile AZ91D to the tough AM60B and the high-temperature WE series, each of these magnesium die casting alloys unlocks specific performance advantages.

However, mastering the alloy is just part of the equation. Success demands a partner with the expertise to guide the selection, engineer the mold, optimize the process, and deliver a finished part that meets the highest standards of quality and performance.

Contact us today for a free, confidential design and alloy consultation. Let’s discuss how the right magnesium die casting alloys can revolutionize your product.