Sand Blasting Services for Casting

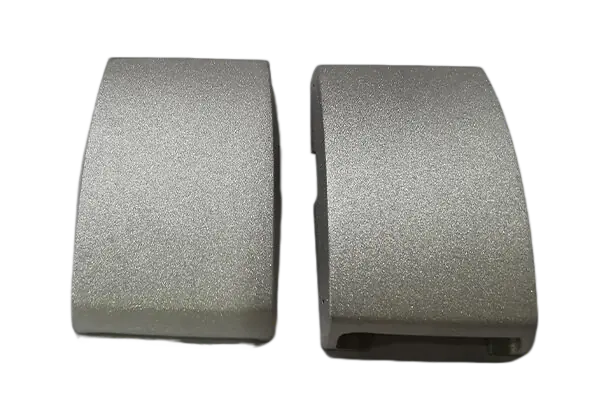

As a professional die casting manufacturer, IEC Mould provides controlled sand blasting services for aluminum and zinc die cast components. By coordinating die casting quality with precisely managed abrasive blasting processes, we deliver uniform surface appearance, stable texture control, and reliable preparation results for both visible and functional parts.

Our sand blasting solutions focus on surface consistency, coating readiness, and process stability—making them ideal for parts requiring cosmetic uniformity or dependable pre-treatment before secondary surface finishing.

- Controlled matte and satin textures

- Improves adhesion for downstream coatings

- Suitable for aluminum and zinc die cast parts

- Ideal for surface preparation and cosmetic uniformity

What Is Sand Blasting for Die Casting?

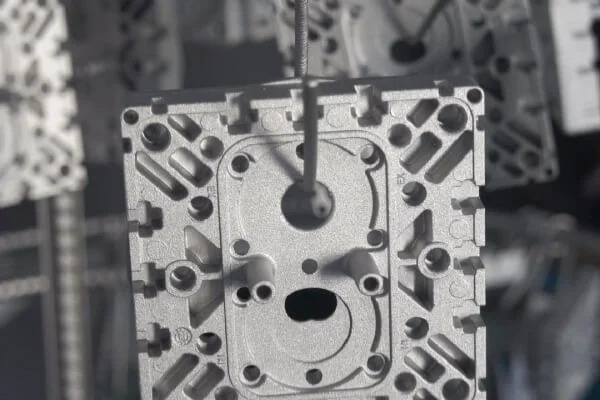

Sand blasting is a mechanical surface finishing process in which controlled abrasive media are propelled onto aluminum or zinc die cast parts to clean the surface, remove minor defects, and create a uniform texture. In die casting applications, sand blasting is commonly used as either a standalone cosmetic finish or a critical surface preparation step before painting, powder coating, anodizing, or plating.

As an experienced die casting manufacturer, we understand that casting porosity, parting lines, ejector marks, and surface texture directly influence blasting results. Proper parameter control is essential to improve appearance without damaging dimensions or functional features.

Unlike chemical surface treatments, sand blasting is a dry, physical process that enhances surface uniformity while maintaining material integrity—especially important for precision die cast components.

Why Sand Blasting Is Widely Used for Die Cast Parts

Sand blasting is one of the most widely applied surface treatments in die casting due to its versatility, controllability, and compatibility with downstream finishing processes.

Key Advantages

- Removes casting residues, flash marks, and surface contamination

- Creates uniform matte or satin surface textures

- Enhances adhesion for painting, powder coating, and plating

- Improves visual consistency across production batches

- Suitable for both cosmetic and functional die cast components

Engineering Reality

Sand blasting is not a simple cleaning step. Excessive pressure, incorrect media selection, or uneven exposure can lead to surface erosion, dimensional variation, or inconsistent texture—especially on thin-wall aluminum or zinc die cast parts.

Our Integrated Approach

By integrating die casting and sand blasting under one system, we control casting parameters, surface condition, blasting media, and exposure profiles together. This ensures predictable texture, stable appearance, and reliable performance—without over-processing or unnecessary risk.

Manufacturing Advantage of Integrated Sand Blasting

Most surface texture issues do not originate at the blasting stage—they start during die casting. When casting and blasting are handled by separate suppliers, surface inconsistencies often remain unnoticed until coating failures or cosmetic defects appear.

By integrating sand blasting into our die casting workflow:

- Casting parameters are optimized to minimize surface porosity before blasting

- Parts move directly into blasting without transport damage or contamination

- Blasting parameters are adjusted based on real casting surface feedback

- Each batch follows a standardized workflow from casting to final surface

The result is a clean, uniform, and coating-ready surface—not an aggressive treatment that hides underlying casting issues.

Suitable Materials for Sand Blasting Die Cast Parts

The effectiveness of surface finishing depends not only on the process itself, but also on the casting material and the original surface condition. Aluminum and zinc die castings provide an ideal foundation for sand blasting when casting quality, surface integrity, and process parameters are properly controlled.

Aluminum Die Casting

Common alloys: ADC12, A380, AlSi series

Aluminum die castings respond very well to controlled sand blasting, achieving consistent matte or satin finishes suitable for visible parts or coating preparation.

Why aluminum works well:

- Stable surface response to fine abrasive media

- Excellent base for cosmetic or coating-ready textures

- Supports consistent appearance across batches

Our engineering control:

Blasting pressure, media size, and exposure time are tuned to prevent surface erosion while achieving uniform texture.

Zinc Die Casting

Common alloys: Zamak 3, Zamak 5

Zinc die cast parts benefit from sand blasting when appearance consistency and gentle surface cleaning are required.

Why zinc works well:

- Naturally smooth casting surfaces enhance blasting uniformity

- Ideal for light matte textures and pre-paint preparation

- Supports selective blasting for cosmetic zones

Engineering consideration:

Zinc alloys are more sensitive to aggressive blasting. Our process uses lower pressure and finer media to maintain dimensional stability.

How Our Sand Blasting Process Works — Step by Step

Effective sand blasting is not achieved by aggressive force, but by controlled execution. Each step is designed to deliver consistent surface texture, reliable cleanliness, and predictable behavior for subsequent manufacturing or finishing processes.

1.Pre-Cleaning & Surface Check — Establishing a Stable Starting Point

Before blasting, die cast parts are inspected and cleaned to remove oils, release agents, and loose contaminants. This ensures that abrasive media interacts directly with the casting surface, not with residual films that could cause uneven texture or inconsistent results.

2.Media Selection & Parameter Setup — Defining the Surface Behavior

Blasting media type, particle size, pressure, and exposure profile are selected based on casting alloy, wall thickness, and surface requirements. This step defines how the surface will respond—whether the goal is light cosmetic refinement or functional preparation.

3.Controlled Sand Blasting — Creating Uniform Surface Texture

Abrasive blasting is applied evenly across defined surfaces to remove minor casting marks and create a consistent matte or satin texture. Blasting angles and dwell time are carefully managed to avoid over-processing, edge erosion, or dimensional impact.

4. Feature Protection & Selective Blasting — Preserving Functional Areas

Threads, sealing surfaces, and critical interfaces are protected or selectively treated as required. This ensures surface improvement is applied only where needed, without compromising assembly fit or functional performance.

5. Post-Blast Cleaning — Stabilizing the Finished Surface

After blasting, residual media and fine dust are thoroughly removed. This step stabilizes the surface condition and prevents contamination from affecting handling, inspection, or downstream processes.

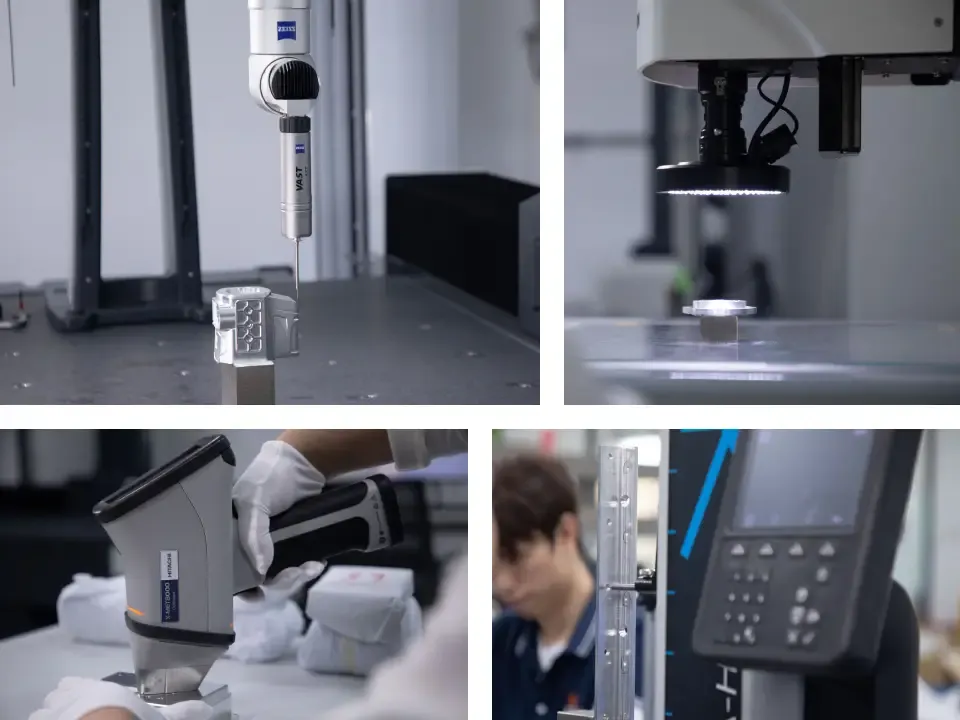

6.Final Inspection & Release — Quality You Can Rely On

Each batch is evaluated for surface uniformity, texture consistency, and visual appearance according to defined requirements. Parts are released only when the blasted surface meets both cosmetic and functional expectations.

Surface Preparation — The Hidden Key to Consistent Sand Blasting Results

In sand blasting, the visible surface texture is only the final outcome. What truly determines uniform appearance, controlled roughness, and process stability happens before abrasive media ever contacts the casting. For die cast parts, surface condition and preparation define how consistently the material responds to blasting energy.

Common Industry Challenges

Die cast components introduce specific challenges that directly affect blasting consistency and surface integrity:

- Micro-porosity or localized density variation can lead to uneven texture development

- Residual release agents or surface contamination may cause inconsistent abrasive interaction

- Variations in as-cast surface condition can result in patchy matte appearance or over-blasted areas

These issues are often difficult to detect on raw castings and only become obvious after blasting—when rework is limited and cosmetic consistency has already been compromised.

Our Control Measures

To ensure repeatable sand blasting results, our control measures focus on how the casting surface reacts to abrasive impact, not simply on surface cleanliness.

- Surface preparation optimized for predictable abrasive response

- Porosity-aware cleaning and inspection to stabilize blasting behavior

- Controlled pre-conditioning steps for sensitive or thin-wall castings

- Defined masking and protection for functional or non-cosmetic areas

This preparation ensures sand blasting delivers uniform texture, controlled material removal, and consistent surface quality—rather than a visually acceptable result on one batch and unpredictable variation on the next.

Sand Blasting Options for Die Cast Parts We Offer

Glass Bead Blasting

– Best for die cast parts requiring a clean, uniform satin or matte appearance with minimal material removal; not suitable where aggressive surface roughening is required.

Aluminum Oxide Blasting

– Ideal for components needing stronger surface texture and enhanced mechanical keying; less suitable for thin-wall or highly cosmetic parts where surface smoothness is critical.

Ceramic Media Blasting

– Used for applications requiring controlled aggressiveness, consistent surface texture, and long media life; suitable for precision die cast parts with stable dimensional requirements.

Multi-Stage Blasting Processes

– Designed for projects requiring tightly controlled surface texture, cosmetic consistency, or preparation for high-spec secondary finishing; involves higher process control compared to single-stage blasting.

Custom Sand Blasted Finishes for Die Cast Parts: Texture, Uniformity & Consistency

As a professional die casting manufacturer, we provide in-house sand blasting services to achieve controlled surface texture, consistent appearance, and reliable surface condition on aluminum and zinc die cast components.

- Surface Texture Control: Light matte to defined satin textures, tailored to cosmetic requirements or downstream finishing needs.

- Uniform Appearance: Even surface tone and texture across visible areas, minimizing casting marks and visual variation.

- Selective Surface Treatment: Targeted blasting with defined protection for threads, sealing surfaces, and functional interfaces.

Unlike decorative coatings, sand blasting does not add a surface layer. Instead, it modifies the existing casting surface, making it ideal for parts where texture control, cleanliness, and surface readiness matter more than color or film build-up.

Key Technical Control & Quality Focus

- Surface Roughness Control: Ra values adjusted according to appearance targets or coating preparation requirements

- Texture Consistency Inspection: Visual and tactile checks to ensure uniform blasting results across each batch

- Dimensional Stability Monitoring: Verification to ensure blasting does not affect critical dimensions or fit

- Process Compliance: Blasting media and handling procedures aligned with applicable environmental and safety standards

By performing sand blasting in-house, we ensure that casting condition, surface preparation, and blasting parameters are managed as one continuous process—delivering predictable surface quality without reliance on external blasting vendors.

Design Guidelines for Sand Blasted Die Cast Parts

Sand blasting delivers the most consistent surface results when it is considered during the die casting design stage, rather than used as a corrective step after casting. Because sand blasting modifies the existing surface, rather than adding a layer, surface quality is strongly influenced by casting geometry, wall thickness, and feature design.

To achieve uniform texture and stable surface condition on die cast parts, we recommend:

- Avoid deep recesses, narrow grooves, or enclosed features where abrasive media cannot reach evenly, which can cause patchy texture.

- Design smooth transitions instead of abrupt changes in surface geometry to reduce over-blasting or inconsistent roughness.

- Clearly define cosmetic and functional areas, especially when selective blasting or masking is required to protect critical surfaces.

- Maintain consistent as-cast surface quality across visible areas to ensure uniform blasting results and minimize variability between production batches.

By aligning die casting design with sand blasting behavior, blasted die cast parts achieve uniform surface texture, predictable appearance, and reliable preparation for downstream processes—without relying on excessive rework or corrective blasting.

While sand blasting provides uniform surface texture and consistent appearance, certain die cast part features require careful evaluation:

- Precision bearing seats or functional surfaces that must remain unaltered to maintain dimensional accuracy and assembly fit

- Threaded or mating features with tight tolerances, where aggressive blasting could alter thread geometry or interfere with torque requirements

- Internal or enclosed areas where abrasive media cannot reach evenly, potentially resulting in inconsistent texture or trapped residue

In these situations, selective masking, fixture-supported blasting, or alternative surface preparation methods may provide more reliable results than full-part blasting, ensuring both functional integrity and controlled surface appearance.

We provide DFM-driven engineering guidance specifically for die casting projects at the quotation stage, with a strong focus on surface texture requirements and sand blasting feasibility.

Our engineers evaluate part geometry, cosmetic zones, tolerance-critical features, and accessibility to determine whether full-part blasting, selective blasting, or alternative surface preparation methods will deliver the most consistent and reliable results — before production begins.

Sand Blasting for Typical Applications of Die Cast Parts

Automotive Components

– Interior and exterior trims, brackets, and housings where uniform surface texture ensures consistent assembly fit and reliable downstream finishing.

Consumer Electronics Enclosures

– Device housings, covers, and frames requiring smooth, controlled surfaces for painting, labeling, or protective overlays.

Industrial Machinery & Control Panels

– Operator interfaces and instrument housings where consistent blasting provides even texture for coatings, adhesives, or tactile surfaces.

Home Appliance Casings

– Washing machines, kitchen appliances, and vacuum cleaner panels where uniform matte or satin finishes enhance visual quality and coating adhesion.

Lighting Fixtures & Electrical Housings

– Die cast parts in visible locations requiring clean removal of casting marks and surface uniformity for secondary finishing.

Decorative Hardware & Furniture Components

– Handles, knobs, brackets, and decorative parts where controlled blasting preserves fine details and supports selective finishing or masking.

Our 6 Quality Controls for Sand Blasted Die Cast Parts

Sand blasting quality for die cast components is ensured through systematic inspection and process control, focusing on surface texture, uniformity, and preparation for downstream processes, rather than decorative coatings.

- Incoming Surface Inspection

Check each batch for as-cast texture, surface integrity, and dimensional stability. - Surface Preparation Verification

Confirm media, pressure, and masking are correct for consistent blasting results. - In-Process Blasting Control

Monitor coverage and media flow to maintain even surface roughness. - Functional Area Protection

Ensure threads, bearing seats, and mating surfaces remain within tolerance. - Texture & Uniformity Evaluation

Assess visual and tactile surface quality to meet design targets. - Batch Traceability

Document each batch to guarantee repeatable surface quality from prototype to production.

Why Sand Blasting Can Be Challenging on Die Cast Parts — How We Control It

Sand blasting outcomes are often influenced by the die casting itself rather than the blasting process alone. Surface geometry, porosity, sharp edges, and inconsistent handling can lead to uneven texture or functional issues. As an integrated die casting and blasting manufacturer, we manage these risks from casting through blasting, not after problems appear.

| What Customers Usually See | Why This Happens on Die Cast Parts | How We Prevent It in Production |

|---|---|---|

| Uneven Surface Texture | Variations in as-cast roughness or micro-porosity create inconsistent blasting results | Controlled surface preparation, media selection, and process parameters to achieve uniform texture |

| Incomplete Coverage in Recessed Areas | Abrasive media cannot reach deep or enclosed features | Selective blasting, masking, and fixture support to ensure even treatment |

| Surface Damage on Critical Features | Threads, bearing seats, or thin walls are sensitive to aggressive media | Use protective masking, adjusted pressure, and softer media to preserve tolerances |

| Edge or Corner Over-Aggressiveness | Sharp or complex edges are prone to localized over-blasting | Optimized blasting angles, media control, and design guidance for edge radii |

| Residue or Contamination Marks | Oils, release agents, or trapped debris interfere with media action | Thorough degreasing, cleaning, and inspection before blasting |

| Texture Variation Between Batches | Differences in casting surface quality or blasting setup | Standardized media handling, process monitoring, and batch documentation for repeatable results |

Sand Blasting vs Other Surface Preparation Methods for Die Cast Parts

Sand blasting provides a controlled, uniform surface texture that is ideal for functional preparation, downstream finishing, and consistent tactile quality. While chemical etching, mechanical polishing, or vibratory finishing offer alternative benefits, sand blasting excels in surface uniformity, edge consistency, and batch repeatability for a wide range of die cast components.

| Feature / Consideration | Sand Blasting | Chemical Etching | Vibratory / Mechanical Finishing |

|---|---|---|---|

| Compatibility with Die Cast Materials | Works on aluminum, zinc, and magnesium; safe for visible and functional surfaces | Mainly aluminum; sensitive to thin walls and sharp features | Works on aluminum, zinc, magnesium; may alter small or delicate features |

| Surface Profile Control | Medium to high; adjustable roughness for downstream finishing | Low to moderate; limited control over micro-texture | Low to moderate; primarily smooths rather than creates uniform texture |

| Edge & Corner Treatment | Precise; can be masked to protect critical edges | Weak on sharp or intricate edges | Moderate; may round off edges unintentionally |

| Texture Consistency | High; repeatable across batches and production runs | Moderate; dependent on chemical concentration and exposure | Moderate; depends on media and duration, less uniform on complex shapes |

| Geometry Compatibility | Excellent for visible and selective areas, recesses, or complex surfaces | Limited on enclosed or intricate features | Good for bulk surfaces, less effective in deep recesses |

| Production Volume Suitability | Low to high; from prototypes to large-scale batches | Low to medium; often slow and chemical-intensive | Medium to high; effective for bulk finishing but less precise on cosmetic areas |

| Design & Functional Flexibility | Excellent; supports selective blasting, masking, and downstream coatings | Limited; mainly surface cleaning or light etching | Moderate; mainly for deburring, polishing, or smoothing |

Key Takeaway

For die cast parts requiring consistent surface texture, uniform preparation for secondary processes, and selective area control, sand blasting is the preferred method. Chemical etching is suitable for light surface modification on aluminum, while vibratory or mechanical finishing works for bulk smoothing but lacks precise control on edges or recesses. Sand blasting combines precision, repeatability, and functional readiness, making it ideal for both cosmetic and high-performance applications.

Why Customers Choose IEC Mould for Their Sand Blasted Die Cast Parts

At IEC Mould, we deliver consistently high-quality sand blasted die cast components that meet both functional and visual requirements for global projects and engineering-driven applications.

- Precision-focused production: Our integrated process ensures each part achieves uniform surface texture, consistent roughness, and controlled profiles, even for prototypes or low-volume runs.

- Full in-house process control: From die casting and surface preparation to blasting, every stage is monitored to maintain texture uniformity, edge protection, and batch-to-batch consistency.

- Flexible and targeted surface finishing: We support selective blasting, masked areas, and custom texture requirements to meet both functional and cosmetic design goals.

- Proven global expertise: Our die casting and sand blasting capabilities have reliably delivered surface preparation and functional quality for international clients across automotive, electronics, industrial, and consumer industries.

Start Your Sand Blasting Die Cast Project

Contact our engineering team to discuss your application, part design, and sand blasting requirements.

Our experts work with you to ensure uniform surface texture, precise edge protection, and consistent functional preparation—helping your die cast parts meet both performance and cosmetic standards without surprises.