In the competitive landscape of manufacturing, particularly for markets like automotive and aerospace, magnesium alloys are prized for their exceptional strength-to-weight ratio. However, the full potential of this “green engineering material” is only unlocked with the right production core: a precision Magnesium Die Casting Machine. Selecting the appropriate machine is not merely a purchase; it’s a strategic decision impacting part quality, production efficiency, and ultimately, your profitability. This guide moves beyond basic spec sheets to help you understand the technology, make an informed choice, and leverage a true integrated solution.

Hot Chamber vs. Cold Chamber: Selecting the Right Process for Magnesium

The first critical choice revolves around the casting process. Understanding the distinction is fundamental to selecting the correct Magnesium Die Casting Machine.

Magnesium Die Casting: Hot Chamber vs. Cold Chamber

Select the optimal process for your project to maximize efficiency and quality

Hot Chamber Die Casting

Cold Chamber Die Casting

Key Decision Factor: Hot chamber is optimal for small-to-medium, thin-wall, high-volume production; Cold chamber is suited for medium-to-large, thick-wall parts requiring high strength.

Hot Chamber Machines are typically used for high-volume production of smaller to medium-sized components. The injection mechanism is immersed in the molten magnesium, allowing for faster cycle times. This process is highly efficient for alloys with lower melting points and is common for precision components.

Cold Chamber Machines are essential for larger components or alloys requiring higher pouring temperatures. The molten metal is ladled into a separate chamber before being injected, offering greater flexibility and control for structurally demanding parts like automotive frames.

Is your primary output high-volume, small components? A hot chamber Magnesium Die Casting Machine may be optimal. Are you casting large, thick-walled parts? Then, a cold chamber system is likely necessary.

The 5 Core Systems of a Modern Magnesium Die Casting Machine

A top-performing machine is the sum of its advanced subsystems. Here’s what to scrutinize:

The Clamping Unit

This system provides the force to keep the mold sealed against immense injection pressure. Look for high-rigidity toggle or direct-lock systems that ensure stability, precision, and longevity, even in high-speed cycles.

1. Clamping System

Core Function: Provides massive force to keep the mold tightly closed during high-pressure injection, preventing molten metal leakage.

It utilizes a hydraulic double-toggle mechanism to amplify the hydraulic cylinder's thrust by 16-26 times, ensuring a secure lock with minimal energy consumption. The movement follows a smooth slow-fast-slow speed pattern for safe and efficient cycling.

- Stationary Platen

- Moving Platen

- Tie Bars (Gib Columns)

- Toggle Mechanism

- Clamping Cylinder

The Injection System

The heart of quality. Key metrics like injection speed (often >8m/s) and intensification pressure build-up time (<20ms) directly determine the metallurgical integrity and surface finish of the casting.

2. Injection System

Core Function: Drives molten metal into the mold cavity at preset speeds and pressures; the heart of casting quality.

This system executes a precise sequence: Slow Shot (seals the pour hole) -> Fast Shot (fills the cavity at >8m/s) -> Intensification (applies extreme pressure to eliminate porosity). Modern systems use advanced PID control for unparalleled accuracy.

- Injection Cylinder

- Shot Sleeve (Cold Chamber)

- Plunger (Piston)

- Accumulators (Fast Shot & Intensification)

- Servo/Proportional Valves

Melting & Safety Systems

Magnesium requires dedicated safety. A modern Magnesium Die Casting Machine must include an advanced, sealed melting furnace with a protective gas (like SF6 or SO2 blends) system to prevent dangerous oxidation.

3. Melting & Pouring System

Core Function: Melts alloy into homogeneous, temperature-qualified molten metal and transfers it safely to the injection system.

For magnesium alloys, this is critical. It requires a fully sealed furnace with a protective gas system (e.g., SF6 mix) to prevent dangerous oxidation. Metal transfer can be automated via a dosing furnace or manual ladle.

- Sealed Melting Furnace

- Protective Gas Supply

- Automatic Ladle / Pouring Robot

- Temperature Sensors & Controls

The Control System

The brain of the operation. A sophisticated PLC with real-time shot monitoring and data logging is non-negotiable for repeatability, traceability, and predictive maintenance.

4. Control System

Core Function: The "brain" that coordinates all subsystems to operate precisely according to set parameters.

Using a high-performance processor (e.g., ARM, DSP, or PLC) and sophisticated algorithms like fuzzy PID control, it ensures repeatability. It provides real-time P-Q² diagram monitoring, data logging for traceability, and interfaces for full automation integration.

- Industrial PLC / Dedicated Controller

- HMI (Touch Screen Interface)

- Sensors (Position, Pressure, Temperature)

- Data Acquisition & Processing Modules

Energy & Automation Readiness

Modern machines offer servo-driven hydraulic systems for significant energy savings. Built-in interfaces for robotics (for extraction, spraying) and temperature control units are essential for a future-proof cell.

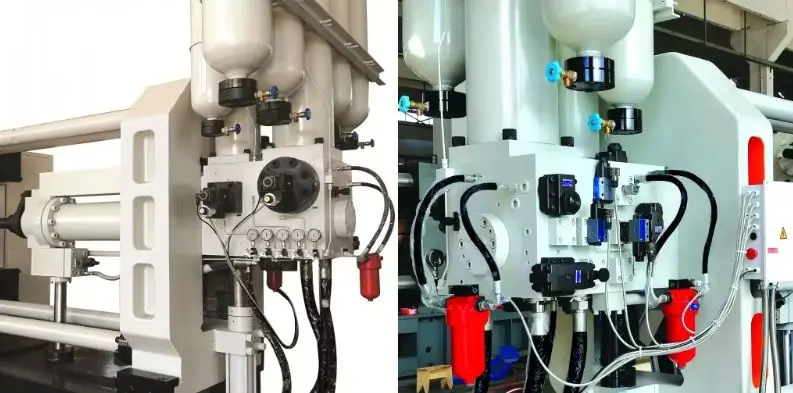

5. Hydraulic System

Core Function: Provides stable, controllable power for all machine movements; the "muscle" of the machine.

It consists of hydraulic pumps, valves, cylinders, and accumulators. Modern machines employ servo-driven pumps that supply oil on demand, reducing energy consumption by 30-60% compared to traditional fixed-displacement pumps. Accumulators act as energy reservoirs for instantaneous high-power demands like the fast shot.

- Hydraulic Pump (Servo/Variable)

- Accumulators

- Control Valves (Direction, Pressure, Flow)

- Hydraulic Cylinders

- Oil Tank, Cooler, Filters

Specifying Your Machine: A Practical Guide Beyond the Brochure

Moving from theory to specification requires a structured approach.

Step 1: Define Your Product & Output

Reverse-engineer on your part. Calculate the required clamping force (in tons or kN) based on the projected area of the part in the mold. Determine the necessary shot weight and platen size to accommodate your mold.

Step 1a: Technical Deep Dive – Key Calculations for Machine Sizing

Clamping Force Calculation with a Real-World Example

- Part & Runner Projected Area: 300 cm²

- Intensification Pressure: ~800 kg/cm² (for structural magnesium parts)

- Safety Factor: 1.2Calculation: 300 cm² × 800 kg/cm² × 1.2 = 288,000 kg or 288 Tons.Result: A standard 350-ton cold chamber machine would be the optimal choice, providing a robust margin for stable production.

Optimizing Shot Sleeve Fill Ratio for Quality

- Shot Weight: 1.9 kg of magnesium (density ≈ 1.7 g/cm³) = ~1118 cm³.

- Shot Sleeve Volume (70mm dia. x 400mm length): ~1539 cm³.

- Fill Ratio: (1118 / 1539) × 100% ≈ 72.6% (Ideal).A ratio in this range helps minimize air entrapment for superior part integrity.

Machine-Mold Matching with the P-Q² Diagram

- Machine Line: Represents the maximum pressure/flow the machine can deliver.

- Mold Line: Represents the flow resistance of your mold’s gating system.The intersection of these lines is the operating point. A modern machine with a dry shot speed >8 m/s and pressure build-up time ≤15ms provides a high “Machine Line,” offering a wide operating window to successfully fill complex, thin-wall molds.

Step 2: Define Quality & Advanced Requirements

Will you need vacuum assistance to produce pore-free structural parts? Does your process require a quick mold change system for flexible manufacturing? These features should be specified up front.

Step 2a: Advanced Process Technologies for Structural Integrity

Leveraging Vacuum Die Casting for Pore-Free Structural Parts

For automotive structural components and aerospace parts where porosity is unacceptable, vacuum die casting is a critical technology. It involves extracting air and gases from the mold cavity immediately before and during the injection of molten magnesium.

The Mechanism: How Vacuum Enhances Density

The core principle is to create a low-pressure environment (typically achieving vacuum levels of 50-100 mbar or less) within the die cavity. This dramatically reduces the amount of air entrapped in the molten metal. As a result, the incidence of gas pores is minimized, leading to a denser, more homogeneous microstructure . This improvement in integrity allows the castings to be heat-treated (e.g., T5 or T6 temper) without the risk of surface blistering, and significantly enhances the mechanical properties—particularly elongation and fatigue strength—making them suitable for safety-critical applications .

High-Vacuum Parameters and Implementation for Magnesium

- Optimized Vacuum Valves and Ducting: Specially designed systems that ensure rapid evacuation without being clogged by molten metal.

- Advanced Die Sealing: Critical for maintaining the vacuum, requiring precise machining of die components and the use of specialized seals at the parting line and around ejector pins.

- Process Synchronization: The vacuum pump must be perfectly synchronized with the injection cycle, initiating evacuation just as the die closes and maintaining it throughout the filling phase . Implementing this technology is a key decision for producing large, thick-walled magnesium parts that compete with aluminum and steel fabrications.

Step 3: Evaluate the “Complete Package”

The best Magnesium Die Casting Machine is supported by deep application expertise. Consider the supplier’s ability to provide integrated automation, process debugging, and long-term technical support.

Beyond the Machine: The Value of an Integrated Solution

Purchasing a magnesium die casting machine in isolation overlooks a crucial opportunity. The greatest efficiency gains come from seamless integration.

Mold-Machine Synergy

When mold design is informed by the specific dynamics of your Magnesium Die Casting Machine, issues like poor filling or premature wear are minimized from the start.

Achieving Perfect Harmony: Mold and Machine Co-Design

The highest levels of part quality and production efficiency are achieved when the mold design and the machine’s capabilities are developed in tandem. This co-design philosophy prevents common defects and extends the life of both the mold and the machine.

Special Considerations for Magnesium Alloy Mold Design

- Gating System: Due to magnesium’s faster solidification rate compared to aluminum, the gating system (sprue, runners, and gates) must be designed for extremely rapid filling. Gates are often wider and thinner to achieve the necessary high-speed metal flow that prevents premature freezing.

- Cooling Channels: The high thermal conductivity of magnesium requires precise temperature control. Conformal cooling channels that follow the contour of the mold cavity can provide a more uniform thermal profile, reducing cycle times and minimizing thermal stress on the die steel.

- Venting: While vacuum systems remove most of the air, effective venting at the end of fill and along parting lines remains critical to allow the last traces of air to escape, preventing burns and short shots.

Machine-Mold Matching Optimization Principles

- Clamping Force Verification: The machine’s clamping force must sufficiently exceed the total injection pressure acting on the projected area of the part (including the runner system) to keep the die closed. Undersized force leads to dangerous flash; oversized force wastes energy and can damage the machine or mold .

- Injection Performance Profile: The mold’s required filling time and pattern must lie well within the machine’s P-Q² capability. A machine that cannot provide the necessary flow rate (Q) at the required injection pressure (P) will result in mistuns or cold flakes. Advanced machine controllers now allow for multi-phase injection profiling to perfectly match the mold’s filling characteristics .

Mold-Machine Synergy Design Visualization

Precise coordination between mold design and machine parameters is critical for achieving high-quality magnesium die casting production.

Traditional Gating Design

Unstable metal flow, slow filling speed, prone to cold shut defects

Optimized Gating Design

Fan-shaped expanding gate, rapid and stable metal filling, optimized for magnesium characteristics

Key Technical Considerations

Rapid Filling Design

For magnesium's fast solidification, gate design must ensure cavity filling within 0.025-0.04 seconds

Flow Simulation Optimization

Software like ProCAST simulates filling process to optimize gating and prevent air entrapment and cold shuts

Gate Area Calculation

Ingate area calculated by formula Ag=V/vt to ensure filling velocity of 45-55 m/s

Mold Temperature Controller System Operation

Heating & Cooling Cycle

Temperature controller heats thermal medium (water/oil) via electric heating elements, precisely controlling mold temperature in closed loop

Precise Temperature Control

PID regulation maintains mold temperature within ±1°C of setpoint, reducing thermal stress deformation

Thermal Balance Design

Evenly distributed cooling channels eliminate local overheating, ensuring uniform solidification rate for magnesium

Die Casting Machine Side

Mold Side

Precision Interface Coordination Points

Standardized Interface Design

Standardized interfaces between mold and machine ensure quick changeover and precise positioning, minimizing downtime

Real-time Data Exchange

PLC control system enables real-time data exchange between machine and mold for optimized process parameters

Hydraulic System Synchronization

Machine hydraulic system precisely coordinates with mold core-pulling mechanisms for multi-stage sequential control

The Automated Cell

A machine integrated with a robotic extractor, trim press, and conveyor transforms into a continuous production cell, maximizing uptime and consistency.

Process Partnership

A supplier who offers ongoing process optimization ensures your investment yields the highest quality and lowest cost per part over its entire lifecycle.

FAQ

Is protective gas absolutely necessary for a Magnesium Die Casting Machine?

Yes. Molten magnesium reacts rapidly with oxygen. A sealed furnace with a reliable protective gas (cover gas) system is a mandatory safety and quality feature to prevent oxidation and fire risk.

Can I use an aluminum cold chamber die casting machine for magnesium?

It is strongly discouraged. Magnesium-specific machines have crucial safety adaptations in the melting, injection, and control systems to handle the unique properties and risks of magnesium alloys.

What is the typical lead time for a new Magnesium Die Casting Machine?

Lead times vary by manufacturer and specification but typically range from 4 to 8 months for a standard configuration. Discuss timelines early with your supplier.

Conclusion

Choosing the right Magnesium Die Casting Machine is a complex but critical decision that defines your manufacturing capability. By focusing on the synergy between process technology, machine subsystems, and holistic integration, you invest in long-term competitiveness.

Ready to specify your next high-performance magnesium casting cell? Contact our engineering team today for a confidential consultation on your project requirements and explore our integrated solutions.