How to Choose the Right Zinc Die Casting Manufacturer

Choosing a zinc die casting manufacturer may seem straightforward at first glance. A quick online search delivers dozens of suppliers, all promising high quality, competitive pricing, and fast lead times. However, from a real-world manufacturing perspective, selecting the right zinc die casting partner can directly impact product quality, tooling life, production stability, and long-term cost.

This article explores how to select a qualified zinc die casting manufacturer by examining the technical, quality, and operational factors that directly impact product performance. It is intended for companies sourcing custom zinc alloy parts across automotive, electronics, hardware, and industrial sectors.

Why Choosing the Right Zinc Die Casting Manufacturer Matters

Zinc die casting is widely used for producing complex, high-precision components with excellent surface finishes and tight tolerances. But the process is only as good as the manufacturer behind it.

The right zinc die casting manufacturer can:

- Improve part consistency and dimensional accuracy

- Extend mold life and reduce tooling costs

- Shorten lead times and improve delivery reliability

- Support design optimization and future scaling

On the other hand, choosing the wrong supplier often leads to quality issues, unexpected delays, and higher total project costs. That’s why supplier selection should be treated as a strategic decision—not just a purchasing task.

Evaluate Engineering & Design Support Capabilities

One of the first things to assess is whether the zinc die casting supplier offers engineering and design support, not just production.

A qualified manufacturer should be able to:

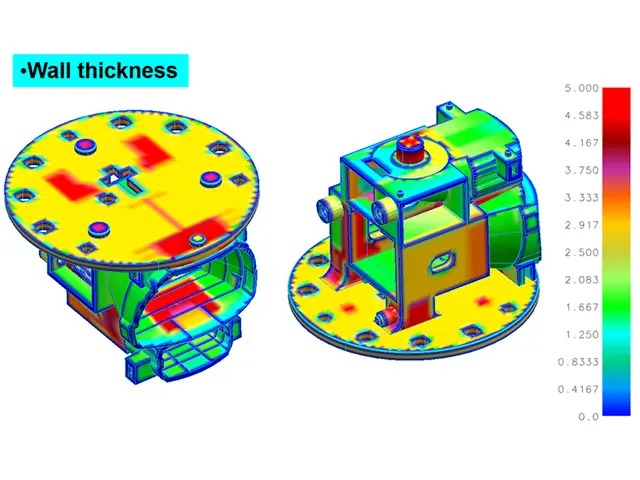

- Provide DFM (Design for Manufacturability) feedback

- Optimize wall thickness, draft angles, and part geometry

- Support mold flow analysis and early risk identification

- Assist with prototyping and pre-production validation

From an engineering standpoint, early collaboration often determines the success of the entire project. Manufacturers with strong technical teams help reduce revisions, prevent defects, and lower overall production costs.

Check Quality Control Systems & Certifications

Quality control is a key differentiator among zinc die casting manufacturers. Rather than relying on final inspection alone, top suppliers build quality into every stage of the process.

When evaluating a manufacturer, look for:

- ISO 9001 or IATF 16949 certification

- Documented quality management systems

- Statistical process control (SPC)

- In-house inspection equipment such as CMMs, X-ray testing, and surface measurement tools

As many experienced engineers say, quality is not inspected at the end—it is designed into the process. A precision zinc die casting manufacturer should be able to provide traceable inspection reports and clear quality documentation.

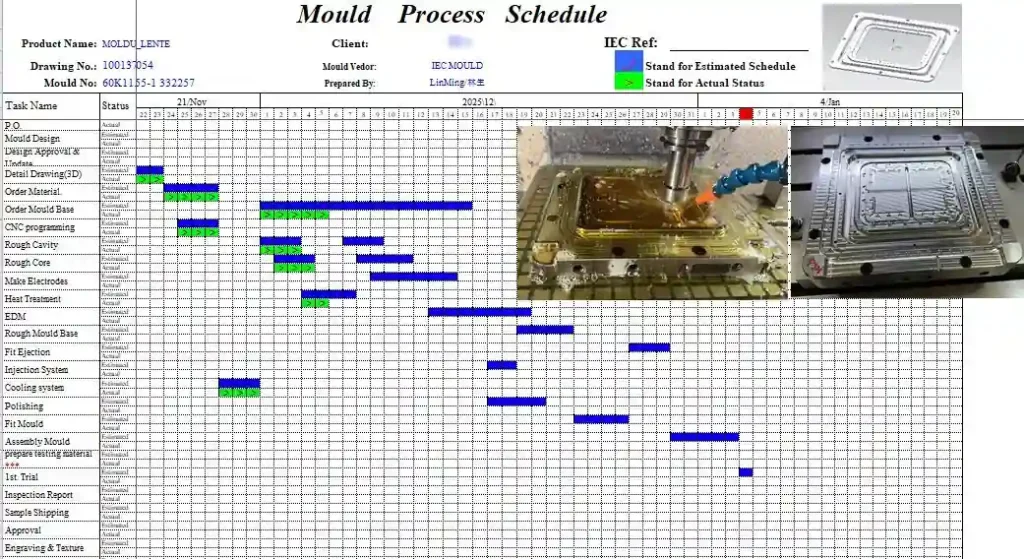

Assess Production Capacity & Lead Time Reliability

Production capacity and lead time consistency are critical, especially for growing or high-volume programs.

Key factors to review include:

- Die casting machine tonnage range

- Monthly and annual production capacity

- Sample lead time vs. mass production lead time

- Ability to scale production when demand increases

A reliable zinc die casting factory should have balanced capacity planning and clear communication around scheduling. This ensures stable deliveries without compromising quality.

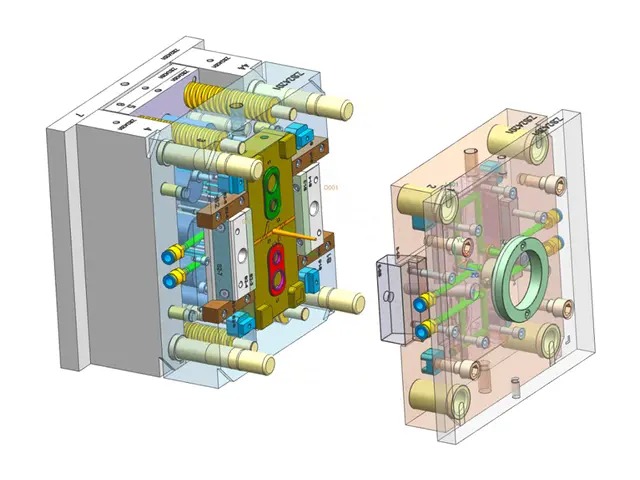

Review Mold Design & Tooling Expertise

The mold is the foundation of any zinc die casting project. Poor mold design leads to defects, frequent maintenance, and shortened tool life.

When selecting a zinc die casting manufacturer, ask:

- Is mold design handled in-house or outsourced?

- How is mold life monitored and maintained?

- How quickly can tooling modifications be made?

Manufacturers with strong tooling and mold design capabilities can significantly reduce downtime, improve part consistency, and lower long-term costs.

Compare Cost Beyond the Unit Price

While price is always an important factor, focusing solely on unit cost can be misleading. A low initial quote may hide higher costs later in the project.

Instead, evaluate:

- Total project cost over the product lifecycle

- Scrap and rework rates

- Secondary operations and finishing requirements

- Tooling durability and maintenance expenses

An experienced zinc die casting supplier helps optimize part design and production efficiency, resulting in better value—not just a lower price per piece.

Communication, Experience & Industry Focus

Clear communication and relevant industry experience often separate good suppliers from great ones.

Look for manufacturers who:

- Have experience in your target industries (automotive, electronics, hardware, industrial)

- Assign a dedicated project manager

- Communicate clearly in technical English

- Respond quickly to engineering or production questions

Strong communication reduces misunderstandings, shortens development cycles, and builds long-term trust.

Final Checklist: How to Choose the Right Zinc Die Casting Manufacturer

Before making your final decision, make sure your supplier meets these key criteria:

- ✅ Engineering and design support

- ✅ Certified quality management systems

- ✅ Reliable production capacity and lead time

- ✅ Strong mold design and tooling expertise

- ✅ Transparent cost structure

- ✅ Clear and responsive communication

This checklist can help you quickly compare zinc die casting manufacturers and identify the best long-term partner for your project.

Conclusion: Partner for Long-Term Success

Choosing the right zinc die casting manufacturer is not just about finding a supplier—it’s about building a partnership. A reliable manufacturer supports your product from design to mass production, helps control costs, and ensures consistent quality as your business grows.

Thank you for tuning in to today’s episode. If you’re planning a new zinc die casting project or looking for a more reliable manufacturing partner, taking the time to evaluate suppliers carefully will pay off in the long run.

IEC MOULD (China)

Location: China

Email: sherry@iec-mould.com

Tel: +86-0769-85336570

Website: www.iec-mould.com