Have you ever run your finger over a metal part and wondered, “How smooth can a die casting really get?” Is it always grainy, or can it be as sleek as glass? The answer is more visual than you think. While specifications like “Ra 1.6” are precise, they don’t paint the full picture.

In this guide, we cut through the technical jargon. We’ll show you, side-by-side, the full spectrum of die casting finishes—from rough, as-cast textures to stunning mirror polishes. By the end, you’ll not only understand the grades but also know exactly which one is right for your next project.

What Determines Die Casting Smoothness?

Before we dive into the visuals, it’s helpful to know what controls the final feel of a die-cast part. The surface finish isn’t random; it’s the result of several key factors:

Mold Quality & Polish: This is the #1 influencer in die casting. A new, highly polished steel mold will produce a significantly smoother surface than a worn or textured one. Every tiny scratch or pit on the die casting mold will be reproduced on the part.

Alloy Material: Different die casting alloys flow and solidify differently. For example, aluminum-silicon alloys generally provide better surface finish than some zinc alloys, but high-purity zinc can achieve exceptional smoothness.

Process Parameters: The magic triangle of temperature (mold and metal), injection pressure, and speed must be balanced in die casting. Optimized parameters ensure the metal fills the mold perfectly before solidifying, minimizing defects.

Post-Processing: The die casting journey doesn’t end at ejection. Processes like sandblasting, polishing, grinding, or plating can dramatically enhance or alter the final surface.

Now, let’s see what these factors actually produce. There is a professional factory for your reference.

The Complete Visual Guide to Die Casting Finishes

Surface roughness in die casting is typically measured in micrometers (µm) as an Ra (Average Roughness) value. Lower Ra = smoother surface. The chart below gives you a quick reference before we look at real-world examples.

| Finish Level | Typical Ra Value (µm) | Visual Character | Common Applications |

|---|---|---|---|

| As-Cast | 3.2 – 12.5 | Visible grain, rough feel | Hidden structural parts, engine brackets |

| Machine-Gated | 1.6 – 3.2 | Matted, uniform texture | Housing interiors, non-critical covers |

| Standard Production | 0.8 – 1.6 | Smooth to touch, slight luster | Consumer electronics housings, power tools |

| High-Quality | 0.4 – 0.8 | Very smooth, satin sheen | Visible automotive parts, appliance faces |

| Precision | 0.1 – 0.4 | Glossy, near-defect free | Medical device components, optical bezels |

| Polished/Mirror | < 0.1 | Reflective, mirror-like | Decorative trim, luxury goods, reflectors |

Picture Comparison: 6 Levels of Die Casting Smoothness

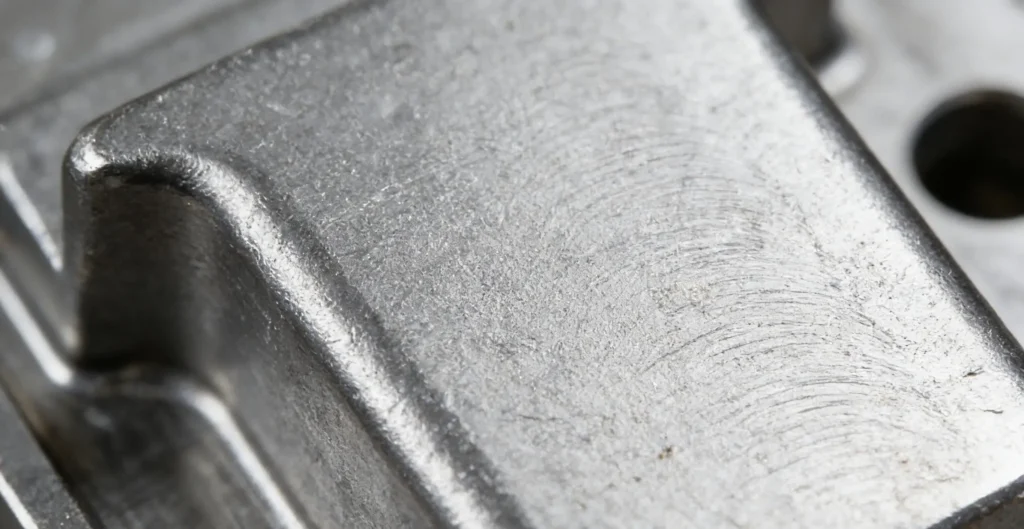

1. As-Cast Finish (Ra 3.2-12.5 µm)

What you see & feel: A distinctly rough, granular surface. You can easily see and feel the grain from the mold texture. Often has visible flow lines or minor imperfections.

Best for: Parts where appearance doesn’t matter—internal structural components, brackets, or bases that will never be seen.

The Bottom Line: The most economical finish, straight from the mold with no additional processing.

2. Machine-Gated / Standard Matte Finish (Ra 1.6-3.2 µm)

- What you see & feel: A uniform, non-glossy matte surface. The rough grain is gone, replaced by a consistent, sandpaper-like feel (though smoother). It’s clean but not reflective.

Best for: The interior surfaces of housings, engine covers, or mechanical parts where a clean, industrial look is sufficient.

The Bottom Line: The workhorse finish for functional components. Reliable and cost-effective.

3. Standard Production Finish (Ra 0.8-1.6 µm)

- What you see & feel: This is the standard for most visible consumer and industrial parts. It feels smooth to the touch and has a slight, satin-like luster under light. Minor tooling marks might be faintly visible.

Best for: Power tool bodies, consumer electronics cases (like router bodies), garden equipment components, and automotive interior parts.

The Bottom Line: The perfect balance of good aesthetics, performance, and cost for a wide range of applications.

4. High-Quality Finish (Ra 0.4-0.8 µm)

- What you see & feel: A noticeably smooth and sleek surface with a consistent satin or fine-brushed sheen. It reflects light softly but clearly. No visible pores or defects to the naked eye.

Best for: High-end appliance faces (blenders, coffee makers), visible automotive components (pedals, trim), and premium DIY tools.

The Bottom Line: Requires excellent mold polish and process control. Conveys a sense of quality and is often ready for painting or coating.

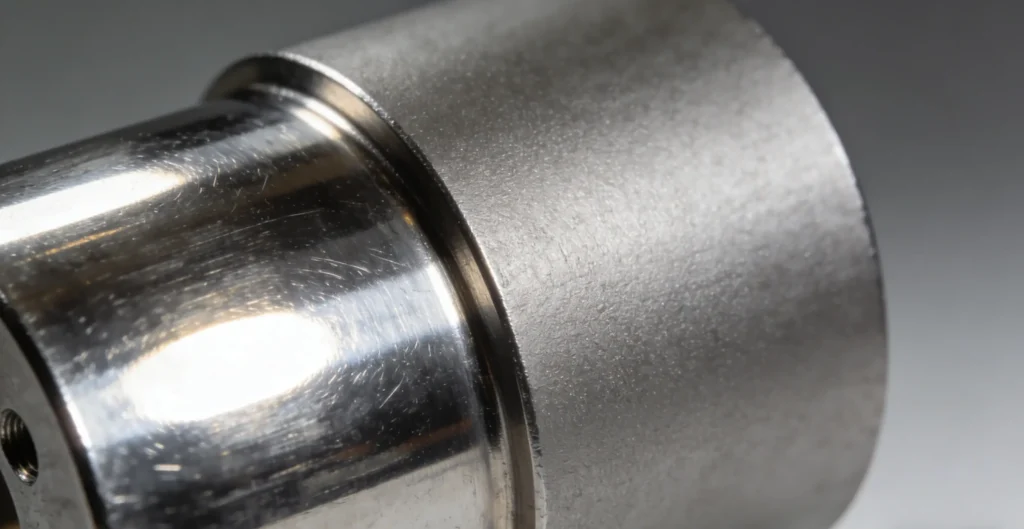

5. Precision Finish (Ra 0.1-0.4 µm)

- What you see & feel: This is where die casting starts to impress. The surface is glossy, highly reflective, and feels like fine ceramic or glass. It is virtually free of any visible casting imperfections.

Best for: Medical device housings, high-precision instrument bezels, optical component holders, and premium consumer tech products.

The Bottom Line: Demands superior mold-making (often with diamond polishing), ultra-clean alloys, and perfect process parameters. Cost increases significantly.

6. Polished or Mirror Finish (Ra < 0.1 µm)

- What you see & feel: The pinnacle of smoothness. The surface is a flawless, highly reflective mirror. It can be difficult to distinguish from a polished wrought metal or even chrome plating.

Best for: Decorative automotive trim, luxury goods components, architectural hardware, and specialized reflectors.

The Bottom Line: Almost always requires extensive post-casting mechanical polishing and buffing. This is a premium finish with a premium price, but it unlocks stunning aesthetic possibilities for metal.

Choosing the Right Finish: Cost vs. Quality

Selecting a finish is an exercise in smart engineering. The smoothest option isn’t always the best. Consider this trade-off:

| Category | Details |

|---|---|

| Cost Impact | Moving from an As-Cast (Ra 3.2) to a Precision (Ra 0.2) finish can increase part cost by 50-200% or more. This comes from higher mold costs, slower cycle times, potential yield loss, and secondary operations. |

| The Rule of Thumb | Specify the roughest finish that meets your functional and aesthetic needs. Does an internal heat sink bracket need a mirror finish? No. Does a faceplate on a luxury device? Probably yes. |

| Think About Coating | If you plan to paint, powder coat, or anodize the part, you can often start with a slightly rougher (and cheaper) base finish, as the coating will fill minor imperfections. |

5 Tips to Improve Your Die Casting Surface Finish

| Optimization Strategy | Details & Key Points |

|---|---|

| Invest in Mold Polish | Don’t compromise on the initial mold finish. A high-polish (SPI A-1 or better) cavity is the foundation for a smooth part. Plan for regular mold maintenance to prevent degradation. |

| Optimize Your Gating & Venting | Proper gate design ensures smooth, laminar metal flow into the cavity. Good venting allows air to escape, preventing trapped gas bubbles (blisters) that ruin the surface. |

| Master the Release Agent | Use the correct type and dilution of die casting release agent. Too much or an improper agent can cause staining, residue buildup, or orange-peel texture. |

| Control the Alloy | Use high-purity, clean alloy with minimal slag or oxides. Contaminants directly lead to surface pitting and defects. |

| Consider Post-Processing | Be open to secondary operations. Vibratory tumbling can improve a standard finish. Light polishing or media blasting (e.g., glass bead) can create attractive uniform textures at a lower cost than a perfect as-cast finish. |

Die Casting Finish FAQs

Can die casting be as smooth as plastic injection molding?

It can get very close! A high-quality Precision Finish (Ra 0.1-0.4 µm) is comparable to many glossy plastic finishes. However, achieving a flawless, injection-mold-like surface on every square inch of a large part is more challenging and costly with metal.

How much more does a mirror finish cost?

A true mirror polish is a significant cost adder. Expect to pay 2 to 4 times the cost of a standard finish part, depending on the geometry. Complex shapes with hard-to-reach areas are especially expensive to polish.

How do I measure the surface roughness of my existing part?

Use a device called a profilometer. Contact stylus profilometers are industry standard, while newer optical/laser profilometers offer non-contact measurement. For a quick check, visual comparison charts (like the one in this article) are surprisingly effective.

Does a smoother finish affect part strength or tolerances?

Not directly. The finish is a surface characteristic. However, the processes to achieve it (like polishing) can remove a tiny amount of material, which must be accounted for in critical tolerance dimensions. The underlying metal’s mechanical properties remain unchanged.

It's All About "Fit for Purpose"

As we’ve seen through these pictures, die casting offers an enormous range of surface smoothness—from the functionally rough to the spectacularly reflective. The journey from an Ra 12.5 to an Ra 0.1 finish is one of escalating precision, control, and cost.

The key takeaway is not to chase the smoothest possible finish, but to identify the optimal finish for your application. Match the surface quality to the part’s role, budget, and user experience. Whether you need the rugged simplicity of an as-cast bracket or the dazzling reflection of a decorative trim, understanding this spectrum empowers you to make the perfect choice.

Ready to specify the ideal finish for your next project? Share your target application in the comments, and let’s discuss which level from our visual guide might be the best fit.