Rapid Prototyping Manufacturer

Looking for fast, precise die casting prototypes or want to validate your design before mass production? As a professional Rapid Prototyping supplier and trusted manufacturing partner, IEC MOULD delivers high-accuracy, durable, and fully functional prototypes tailored to your application. Whether you need aluminum, zinc, or magnesium prototypes, complex geometries, or assembly-fit verification, our prototyping expertise ensures reliable testing, dimensional accuracy, and smooth transition to production — contact us today!

±0.01mm

Tolearance

20+

Years Experience

15 Day

Repid Protyping Samples Delivered

Certifications

ISO 9001 & IATF 16949

Rapid Casting Prototyping Solutions by IEC MOULD

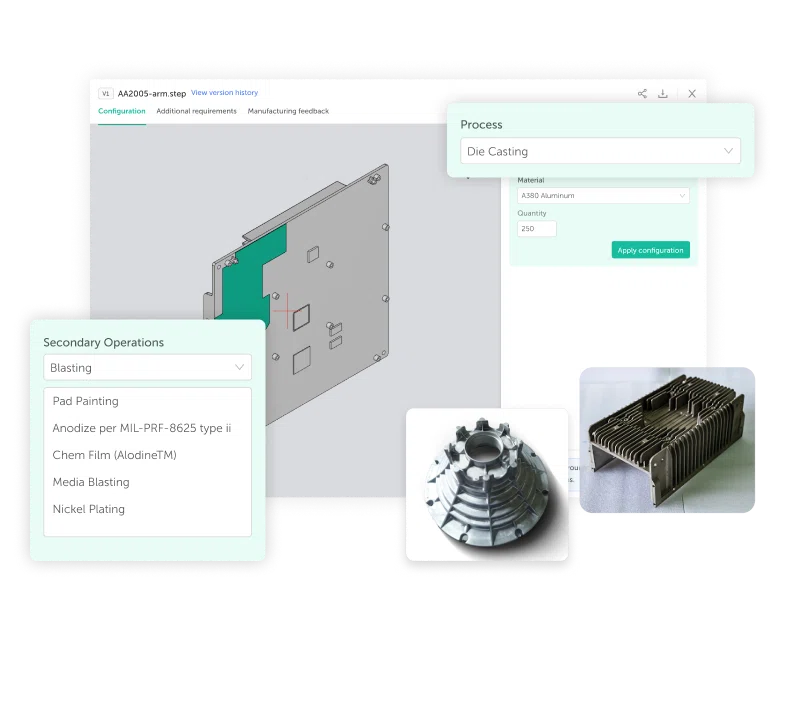

IEC MOULD’s Rapid Casting Services are designed to bring your product ideas to life—fast, accurately, and cost-effectively. Whether you are developing a new automotive component, testing an industrial device, or creating a medical device prototype, our comprehensive rapid casting capabilities allow you to validate designs, perform functional testing, and prepare for production without waiting for full tooling or large-volume investment. By leveraging our in-house engineering, moldflow simulation, tooling, and post-processing expertise, IEC MOULD ensures your prototypes not only meet your specifications but also mimic the performance of production-ready parts.

Key Benefits for Our Customers:

- Speed: Get functional prototypes in 3–15 days, depending on the process and complexity.

- Flexibility: Low-volume production from 1 piece to hundreds.

- Accuracy: Tight tolerances and production-grade finishes.

- Material Variety: Aluminum, zinc, magnesium, steel, brass, and more.

- Engineering Support: Design optimization, DFM, and functional validation.

IEC Mould's Rapid Casting Capabilities

| Details | Specifications |

|---|---|

| Dimensional Accuracy for Rapid-Cast Components | Our rapid casting and prototype casting processes achieve ±0.05–0.10 mm accuracy for functional prototypes and low-volume manufacturing. After CNC machining, tolerances improve to ±0.01–0.03 mm, ideal for precision rapid prototyping, sealing surfaces, and assembly-critical components. |

| Minimum Wall Thickness for Rapid Casting | Depending on the rapid manufacturing method: investment casting prototypes support 0.8–1.5 mm thin walls; sand casting prototypes support 2.5–4.0 mm; rapid die casting supports 1.2–2.0 mm. Perfect for lightweight housings, aluminum rapid casting, and fast design validation builds. |

| Uniform Wall Structure Requirement | For stable prototype casting quality, adjacent wall thickness transitions follow 1:1.3–1:2.0, reducing shrinkage and improving metal flow—ideal for rapid tooling, thin-wall prototypes, and complex geometries. |

| Fine Details, Threads & Inserts | Supports cast-in holes ≥ 1.0–2.0 mm, micro-features, logos, textures, and basic threads. Custom rapid casting also allows insert molding for bushings and pins, reducing CNC machining time and improving rapid product development efficiency. |

| Draft Angle for Rapid Casting Ejection | Typical draft angles: 1°–2° for rapid die casting, 1°–3° for sand casting, and minimal draft for investment casting. Optimized for customers who need prototypes that match mass production die casting geometry for testing and assembly. |

| Tooling Durability for Rapid Casting | Soft tooling for rapid prototyping (silicone/urethane) supports 20–50 shots, while aluminum prototype tooling for bridge production supports 2,000–10,000 shots. Suitable for pilot runs, market testing, and early-stage engineering builds. |

| Surface Finish Quality | Surface finish ranges from Ra 1.6–3.2 μm for rapid die casting, Ra 3.2–6.3 μm for investment casting, and Ra 6.3–12.5 μm for sand casting. Suitable for polishing, plating, anodizing, painting, or other prototype finishing requirements. |

| Minimum Production Volume | Flexible prototype quantities: 1–10 pcs for concept validation, 20–200 pcs for engineering testing, and 300–3,000 pcs for rapid low-volume production. Ideal for startups, OEMs, and fast market-entry projects. |

| Production Schedule / Lead Time | 3D-printed patterns: 3–7 days; soft tooling: 10–15 days; prototype casting + first articles: 7–12 days. Typical rapid production lead time: 10–25 days, depending on material selection and part complexity. |

Prototype castings We Manufactured

These brass alloy cast components highlight our capability in producing high-precision, corrosion-resistant parts with detailed features and stable dimensional performance. From plumbing fittings and valve bodies to electrical connectors and decorative hardware, each component reflects our commitment to accuracy, durable copper-alloy metallurgy, and consistent quality in brass pressure casting manufacturing.

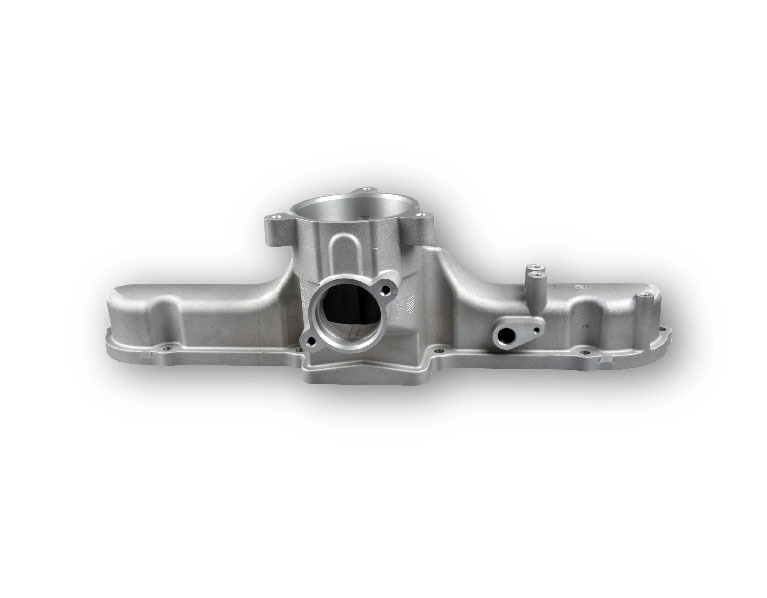

Engine Component made by Rapid Prototyping

Aluminum Cover made by Rapid Prototyping

Automotive In-take Tube made by Rapid Prototyping

Aluminum Housing made by CNC Rapid Prototyping

Camara Parts made By Rapid Casting

Telecom Cover made By Rapid Prototyping

Choosing the Right Material for Your Casting Prototyping Project

Selecting the proper material is essential for ensuring your prototype cast parts meet performance expectations during design validation, functional testing, and pilot production. Whether your project requires rapid investment casting prototypes, low-volume die cast prototypes, or functional metal prototype parts, IEC MOULD’s engineering team evaluates mechanical strength, heat resistance, surface finish, and manufacturability to recommend the ideal alloy for stable, accurate prototype casting results.

Material Options for Casting Prototyping

| Material | Key Characteristics | Typical Prototype Applications | Why It Excels in Prototype Casting |

|---|---|---|---|

| Aluminum A356 / A356-T6 | Lightweight, good fluidity, strong mechanical properties, excellent post-machining performance | EV housings, brackets, lightweight structures, heat-dissipating components | Ideal for prototype casting requiring high strength-to-weight ratio, fast mold filling, and production-equivalent mechanical testing. |

| Aluminum ADC12 / A380 | High castability, stable dimensions, good strength, cost-effective | Consumer electronics samples, auto interior components, connector housings | Best for rapid die casting prototypes where thin walls, tight tolerances, and mass-production consistency are required. |

| Zinc Alloy (Zamak 3 / 5) | Excellent detail reproduction, low porosity, superior surface finish | Small precision prototypes, gear housings, connector heads | Suitable for fine-feature prototype models and small-size engineering parts requiring high accuracy and smooth surfaces. |

| Magnesium AZ91D | Ultra-lightweight, excellent strength-to-weight ratio, good machinability | Mobility components, handheld device prototypes, lightweight engineering parts | Perfect for rapid prototyping where weight reduction and functional performance need to be validated early. |

| Stainless Steel (Investment Casting) | High strength, wear resistance, corrosion resistance | Mechanical assemblies, valve prototypes, structural test components | Ideal for functional prototypes requiring durability, pressure resistance, or corrosive-environment testing. |

| Carbon Steel / Alloy Steel (Investment Casting) | High rigidity, fatigue resistance, precision detail capability | Industrial brackets, load-bearing prototype parts | Suitable for evaluating mechanical strength, load capability, and assembly performance before full production. |

| Copper / Brass Prototype Casting | Good conductivity, excellent surface quality, corrosion resistance | Electrical connectors, decorative samples, HVAC prototypes | Great for validating thermal, electrical, or aesthetic performance before tooling investment. |

Why Our Casting Prototyping Services Trusted by Global Customers

For industries like automotive, industrial equipment, telecom, EV charging, lighting, and consumer electronics, precise and reliable prototypes are essential for design validation and product development. Our casting prototyping team delivers fast, accurate, and functional prototypes that help customers reduce risk and accelerate time-to-market

Our Casting Prototyping Services Inlcude:

- Experienced Engineering Team: Experts in DFM, Moldflow simulation, prototype tooling, process optimization, and quality control.

- End-to-End In-House Solutions: From design analysis and Moldflow simulation to rapid tooling, casting, CNC machining, finishing, and assembly.

- Rapid and Accurate Validation: Prototypes allow testing of critical dimensions, aesthetics, and functionality before full-scale production.

- Flexible Prototyping Methods: Support for a variety of alloys and small-batch casting, enabling realistic evaluation under actual operating conditions.

- Quality-Driven Process: Advanced engineering methods ensure prototypes reflect true performance, supported by IATF 16949 / ISO9001 quality standards.

Why Customers Choose Us?

- Early detection of design or tooling issues

- Shortened development cycles and reduced costs

- Reliable functional and visual testing

- Confidence in mass production readiness

Other Die Casting Metals Services You May Looking for

Rapid Casting Prototypes Frequently Questions & Answers

What is the difference between a prototype and a production part?

Prototypes are primarily for testing design, fit, and function. They may use simplified tooling or small-batch processes but aim to closely replicate production parts.

Can casting prototypes include threads, holes, or other complex features?

Yes, our prototyping process supports complex geometries, functional threads, sealing features, and aesthetic surface details.

How do you handle small-batch or limited prototypes?

We provide flexible tooling options and machine settings to produce small quantities efficiently without compromising prototype quality.

What is the typical lead time for a casting prototype?

Lead time varies by complexity and material, but rapid prototyping solutions can deliver functional prototypes in a few days to a few weeks.

Why is casting prototyping important in product development?

It allows early identification of design or tooling issues, reduces risks, shortens development cycles, and ensures prototypes accurately reflect production parts.

How does casting prototyping differ from 3D printing prototypes?

Unlike 3D printing, casting prototypes use the actual material or similar alloys, providing realistic mechanical, thermal, and aesthetic properties.

What materials can be used for casting prototypes?

Common materials include aluminum, zinc, magnesium, brass, and copper alloys. Selection depends on project requirements and final part performance.

What is Casting Prototyping?

What Is Casting Prototyping?

Casting prototyping is the process of creating functional, test-ready metal parts using rapid tooling and controlled casting methods to validate design intent before full-scale production. It’s how engineers turn ideas into real, touchable, testable components—fast, accurate, and without the compromises common in 3D printing or soft materials.

Prototype cast parts behave like real production parts. They offer true material properties, realistic dimensional stability, and reliable performance under heat, force, or assembly stress. That’s why engineers rely on casting prototyping for early-stage testing, functional validation, and risk elimination long before mass production begins.

Why Do Engineers Choose Casting Prototyping?

Because it gives you real data, not simulation guesses. Prototype castings allow you to check how metal flows, how features fill, how tolerances behave, and how components interact in real assemblies. Whether it’s a 1mm sealing edge, a heat-loaded housing, or a structural bracket, prototyping ensures your final design will work as intended—no surprises later.

Even complex geometries are achievable. Thanks to optimized prototype tooling and controlled casting parameters, molten metal fills thin walls, sharp corners, and intricate forms with ease. Deep ribs, mounting bosses, integrated channels, fine textures—casting prototyping handles them all.

The Hidden Power of Prototype Casting

What engineers love most is how prototyping removes risk from the final production tool. A prototype reveals issues early—flow marks, shrinkage, warpage, weak sections, interference points—so you can fix them before investing in expensive final tooling. One improvement at the prototype stage can save weeks of delays and thousands in corrections later.

Casting prototyping also opens the door to design freedom. You can experiment with design variations, adjust thicknesses, refine structures, and test performance—all without committing to a full production mold. Every iteration becomes smarter, stronger, and more manufacturable.

So what is casting prototyping, really?

It’s the bridge between concept and mass production.

It’s the safest way to validate your design, optimize manufacturability, and eliminate risk—using real metal, real tooling, and real performance.

In simpler terms: Casting prototyping is how you get strong, functional, precision metal parts before the factory starts producing tens of thousands of them.

It’s the engineer’s shortcut to certainty—delivering confidence in every dimension, every feature, and every decision.

Casting Rapid Prototyping Methods

Rapid casting prototyping can be achieved through several tooling and casting approaches, each offering different levels of accuracy, surface quality, speed, and cost. These methods help engineers validate designs early, reduce risks, confirm manufacturability, and accelerate the transition into full-scale production.

Below is an overview of the most widely used rapid casting prototyping methods and how to choose the right solution for your project.

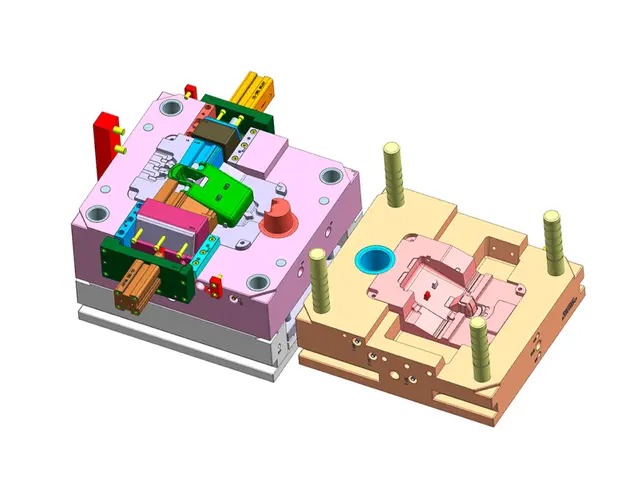

1. Rapid Prototype Tooling (Soft Steel or Aluminum Tooling)

Rapid prototype tooling creates a simplified mold—usually made from P20 steel or aluminum—to produce functional die cast–like parts quickly. This method allows molten metal to be cast under controlled conditions using a lighter, faster-to-machine tool.

Advantages:

- Fast turnaround with realistic casting behavior

- Supports complex geometries, thin walls, and integrated features

- Produces functional parts suitable for mechanical, thermal, and assembly testing

Limitations:

- Tool life is shorter than full production tooling

- Not ideal for very high-volume prototype runs

This approach is the closest simulation of real die casting without committing to the full cost of a production mold.

2. Silicone Mold / Investment Casting Prototyping

For low-volume or intricate prototypes, silicone molds or investment casting can replicate complex shapes with impressive detail. The process uses wax patterns or vacuum-formed replicas to create a precise mold cavity.

Advantages:

- Excellent surface finish and high detail reproduction

- Ideal for internal channels, organic shapes, artistic or decorative components

- Lower initial tooling cost

Trade-offs:

- Slower production cycle

- Not suitable for high-volume prototype batches

- Mechanical properties differ slightly from pressure die casting

This method is often chosen when verifying aesthetics or fine detail before transitioning to metal tooling.

3. Sand Casting & 3D Printed Sand Molds

Sand casting or 3D-printed sand mold prototyping is commonly used for larger components or early-stage functional evaluations. Modern 3D-printed molds eliminate the need for tooling, drastically reducing lead time.

Advantages:

- Very low tooling cost

- Suitable for large or thick-walled prototypes

- Excellent for early functional validation and thermal/mechanical testing

Limitations:

- Lower dimensional accuracy compared to die casting

- Rough surface finish requires post-machining

- Not suitable for thin-walled or fine-detail parts

This approach is ideal for large housings, structural brackets, and heavy components during the initial development phase.

4. Gravity Casting or Semi-Permanent Mold Prototyping

Gravity casting uses reusable molds and molten metal flow under its own weight—sometimes assisted by low pressure—to create higher-quality prototypes than sand casting but at a lower cost than full die casting.

Advantages:

- Good balance of cost, accuracy, and speed

- Better density and fewer defects than sand casting

- Works well for medium-sized structural components

Limitations:

- Less precise than high-pressure die casting

- Limited capability for ultra-thin walls or micro features

This method is commonly applied when testing mechanical strength or dimensional stability.

Choosing the Right Rapid Casting Prototyping Method

High-accuracy, thin-walled prototypes → Rapid Prototype Tooling

Highly detailed or aesthetic-focused prototypes → Silicone Mold / Investment Casting

Large, thick-walled, early-stage prototypes → Sand Casting / 3D Printed Sand Molds

Medium-size functional components → Gravity or Semi-Permanent Mold Casting

Main Steps of Casting Prototyping

As a precision die casting manufacturer, IEC Mould understands that creating prototypes for casting parts is not a simple “sample-making” process. Unlike standard machining or 3D printing, casting prototypes must simulate real metal flow, solidification behavior, shrinkage characteristics, and tooling feasibility. Achieving stable and production-representative prototype parts requires professional engineering evaluation, controlled processes, and prototype-specific tooling strategies.

Below is the typical six-step casting prototyping workflow used by advanced die casting factories. It highlights what truly matters from the viewpoints of engineers, procurement teams, and quality control departments.

Step 1: Prototype Engineering, DFM & Moldflow Simulation

Before any prototype is produced, the engineering team analyzes the part design using DFM and Moldflow to ensure die-castability and identify potential production risks.

Proper engineering ensures:

- Early detection of design flaws

- Reduced tooling modifications

- Prototype parts that accurately reflect mass-production performance

Step 2: Prototype Tooling & Process Selection

Depending on tolerance, quantity, mechanical requirements, and project timeline, the most suitable prototype process is selected.

Typical prototype options include:

- Soft steel or aluminum prototype dies

- CNC-machined samples for high precision

- Gravity or sand casting for thick or large parts

- 3D printing + machining hybrid prototypes for fast iterations

Step 3: Prototype Tooling Fabrication & Mold Preparation

For rapid tooling prototypes, a simplified but production-representative mold is created.

Focus points include:

- Modular inserts for quick design updates

- Simplified cooling channels to reduce tooling cost

- Optimized gating and venting based on simulation

- Mold steel selection suitable for short-run production

- Preheating and release agent application for consistent cycles

Step 4: Prototype Casting & Metal Filling Evaluation

The selected metal (aluminum, zinc, magnesium, or brass) is melted and cast through the chosen process—HPDC, LPDC, gravity casting, or hybrid casting. Process focus includes:

- Controlled metal temperature and holding time

- Adjusted injection parameters to simulate real tooling behavior

- Monitoring for turbulence, cold shuts, or gas entrapment

- Filling trials to verify gating system functionality

Step 5: Trimming, Machining & Surface Finishing

After ejection, prototypes undergo secondary operations to achieve final geometry and appearance.

Common finishing and machining processes:

- CNC machining for threads, sealing surfaces, and precision tolerances

- Deburring, trimming, and gate removal

- Shot blasting, tumbling, sanding

- Powder coating, anodizing, chromate, plating (depending on metal)

- Sub-assembly for multi-component functional prototypes

Step 6: Prototype Inspection & Engineering Validation

All prototypes undergo strict inspection to verify engineering reliability and dimensional accuracy.

Typical prototype testing:

- CMM dimensional measurement

- X-ray or CT scanning for porosity and internal defects

- Flatness, roundness, and critical tolerance verification

- Mechanical property evaluation (hardness, tensile, elongation if required)

- Coating and corrosion performance checks

- Assembly fit testing for multi-part systems

Advantages of Metal Rapid Prototyping

Casting prototyping is the process of transforming a digital design into a real, production-like metal part before committing to full-scale die casting tooling. It allows engineers to validate form, fit, function, and manufacturability while enabling procurement and quality teams to reduce risk and control costs. IEC Mould offers rapid casting prototypes, soft tooling, low-volume casting, and CNC-hybrid solutions to ensure prototypes behave like final production parts.

| Key Advantage | Description |

|---|---|

| Production-Representative Parts | Prototypes replicate real metal behavior, including flow, shrinkage, and structural strength, allowing accurate evaluation before mass production. |

| Fast Design Iterations | Rapid prototyping methods enable quick modifications and functional testing, accelerating product development. |

| Flexible Prototyping Methods | High-pressure, low-pressure, gravity casting, soft tooling, and CNC–casting hybrid methods accommodate different sizes, complexities, and volumes. |

| High Precision & Dimensional Accuracy | Tight tolerances ensure reliable assembly fit, functional surfaces, and consistent testing results. |

| Functional Strength for Testing | Metal prototypes can withstand stress, thermal cycling, vibration, and load tests for real-world validation. |

| Surface Finishing & Cosmetic Evaluation | Supports machining, blasting, coating, or painting to simulate final appearance and inspect surface quality. |

| Design Flexibility & Part Consolidation | Enables integration of multiple features into a single casting, reducing assembly steps and part count. |

| Low-Volume Trial Production | Allows early functional testing and manufacturability verification without full tooling investment. |

| Material Versatility | Supports aluminum, magnesium, zinc, brass, and copper alloys to evaluate mechanical, thermal, and weight properties. |

| Cost-Efficient & Sustainable | Soft tooling and recyclable materials reduce development costs and environmental impact while ensuring accurate prototypes. |

Disadvantage of Metal Rapid Prototyping

When evaluating Metal Rapid Prototyping, it’s important to recognize that—while it offers production-grade material properties and fast design validation—there are also several limitations to consider. Understanding these potential drawbacks helps engineers, procurement teams, and quality departments make informed decisions when selecting the most suitable prototyping method. Below are the primary disadvantages of metal rapid prototyping:

| Disadvantage | Description |

|---|---|

| Higher Cost Compared to Plastic Prototypes | Metal prototypes generally require more expensive materials and specialized tooling, leading to higher per-part cost than polymer or 3D-printed prototypes. |

| Longer Lead Time than 3D Printing | Even rapid casting methods may take days or weeks for tooling, metal preparation, and finishing, slower than plastic additive manufacturing for simple shapes. |

| Limited Design Changes Once Tooling Is Made | Unlike fully digital or 3D-printed models, modifying geometry after the prototype tooling is made can be costly and time-consuming. |

| Surface Finish May Require Post-Processing | Metal cast prototypes often need machining, polishing, or coating to meet aesthetic or functional surface requirements. |

| Size and Complexity Constraints | Extremely large parts or highly intricate internal features may require multiple prototypes or special casting methods, increasing complexity and cost. |

| Material-Specific Limitations | Certain metals may have higher shrinkage, porosity, or thermal conductivity issues, requiring experienced engineering to achieve reliable prototypes. |

| Lower Production Volume Feasibility | Rapid metal prototyping is ideal for low-volume testing; high-volume production is not cost-effective without full production tooling. |

| Specialized Equipment Required | Metal rapid prototyping requires furnaces, casting presses, and skilled operators, which can increase setup complexity and investment. |

Copper & Brass Die Casting vs Other Die Casting Metals

Copper and brass die casting (including high-pressure brass die casting) provides engineers with exceptional strength, conductivity, and corrosion resistance in precision components. Its unique combination of high density, dimensional stability, and thermal/electrical conductivity allows complex geometries, thin walls, and functional features—such as ribs, bosses, threads, and heat-dissipating elements—to be integrated directly into a single part. This reduces secondary machining, assembly steps, and production complexity while maintaining long-term performance and reliability.

Compared to other die casting metals, copper and brass alloys are ideal for applications requiring mechanical robustness, wear resistance, and electrical or thermal conductivity. Fast filling under high-pressure die casting ensures tight tolerances, low porosity, and consistent quality for connectors, valves, housings, fittings, and electrical components.

At IEC Mould, engineers support copper and brass die casting with detailed DFM reviews, mold flow analysis, and alloy selection guidance. By understanding copper’s advantages relative to magnesium, aluminum, and zinc, informed decisions can be made to optimize cost, performance, and manufacturability.

| Property | Copper / Brass Alloys (Cu-Zn) | Magnesium (Mg) | Aluminum (Al) | Zinc (Zn) |

|---|---|---|---|---|

| Weight | Heavy – used where mass, stability, or wear resistance is required | Extremely light – ideal for handheld, portable, and weight-sensitive components | Very light – suitable for large parts | Moderate – provides solid feel |

| Strength & Toughness | Very high – ideal for wear-critical, load-bearing, and structural components; excellent corrosion and fatigue resistance | Moderate to high – excellent strength-to-weight ratio; supports thin-wall, load-bearing parts | High – strong but can be brittle in thin sections | High – strong and impact-resistant for small mechanisms |

| Dimensional Precision | Good – stable for medium to complex geometries; excellent for thin walls under controlled high-pressure die casting | Very good – stable for thin walls and complex geometries with proper tooling | Very good – suitable for most precision applications | Excellent – fine detail and high accuracy |

| Surface Finish | Excellent – naturally smooth, corrosion-resistant; can be polished or plated for aesthetics | Good – usually requires chromate, anodizing, or painting; smooth finish achievable | Good – can be anodized or painted | Superior – can be polished, plated, or coated |

| Thermal Resistance | Excellent – high thermal tolerance and conductivity; suitable for heat sinks, connectors, and valves | Moderate – dissipates heat well; performance drops above 120–150°C | Excellent – performs well in high-heat applications | Limited – loses strength above 150°C |

| Electrical & Thermal Conductivity | Very high – ideal for electrical connectors, thermal components, and EMI shielding | Low to moderate – not ideal for conductivity-critical applications | Moderate – suitable for some electrical/thermal applications | Low – mainly mechanical applications |

| Production Efficiency | Moderate – high melting point requires precise high-pressure die casting; tooling wear higher, but repeatable quality | Moderate to high – rapid solidification allows thin-wall features; oxidation requires careful handling | High – efficient for medium-to-large components | Outstanding – low melting point enables fast cycles and long tool life |

| Cost Efficiency | Lower – higher raw material and energy cost; specialized tooling required; offset by performance, durability, and reduced maintenance | Moderate – higher material cost than aluminum, specialized tooling required, but weight savings offset cost | High – good balance of cost and performance | Excellent – minimal waste, fast cycles, long tool life |

| Typical Applications | Electrical connectors, precision valves, plumbing fittings, decorative hardware, marine components, heat-transfer modules | Automotive brackets, EV housings, aerospace structures, handheld electronics, precision casings | Engine covers, structural housings, heat sinks, large frames | Small gears, connectors, locks, hinges, decorative components |

Copper & Brass Die Casting Part Applications Across Industries

Copper and brass die cast parts are widely used where mechanical strength, corrosion resistance, thermal and electrical conductivity, and dimensional precision are required. These alloys allow intricate geometries, thin-wall designs, and consistent tolerances under high-pressure die casting, producing ready-to-use components that perform reliably in demanding industrial, automotive, electronics, and consumer applications.

| Industry | Typical Components | Why Copper & Brass Die Casting Fits |

|---|---|---|

| Automotive & EV | Engine brackets, connector housings, valve bodies | High strength and corrosion resistance for structural and functional components; excellent thermal and electrical conductivity for electronics and sensors |

| Aerospace & Aviation | Avionics enclosures, actuator brackets, heat exchangers | Dimensional stability and reliability under harsh conditions; lightweight yet strong for load-bearing assemblies |

| Consumer Electronics | Connectors, heatsinks, terminal blocks | Superior electrical and thermal conductivity; precise, intricate geometries enable compact designs |

| Industrial & Machinery | Pump housings, gears, valve bodies, sensor enclosures | High wear resistance, corrosion protection, and durability for heavy-duty applications; supports integrated designs |

| Electrical & Power | Switchgear components, busbars, contacts | Outstanding conductivity and precise tolerances ensure reliable performance in high-voltage or high-current systems |

| Plumbing & Fluid Systems | Fittings, valves, couplings | Excellent corrosion resistance in water, chemicals, and harsh environments; dimensional accuracy ensures leak-free assembly |

| Telecommunications & Networking | Connector shells, shielding enclosures | High conductivity, EMI shielding, and robust mechanical strength for sensitive electronic components |

| Marine & Offshore | Propeller components, valve bodies, connectors | Corrosion-resistant in seawater and harsh climates; suitable for structural and functional marine parts |

Ready to Start Your Brass/Copper Die Casting Parts?

Our experienced engineers are here to guide through brass alloy selection, mold design, and production optimization. Discover how advanced brass die casting technologies can deliver high-quality, durable, and cost-efficient components for the next brass casting project

- yoyo@iec-mould.com

- 86 13712993487

- 86 13712993487

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.