Die Casting Engineering Services – Powered by IEC MOULD

IEC Mould provides advanced DFM, Moldflow, and precision tooling engineering to ensure parts are right the first time and stable in mass production. Trusted by OEM and Tier-1 customers for aluminium, zinc, and magnesium die-casting projects.

- ISO 9001:2015 & IATF 16949 Certified

- 20 + Years Experience

- Full in-house service

Engineering — The Foundation of Reliable Die Casting Production

Choosing a die casting partner is not just about machine tonnage, brand names, or an equipment list. In real manufacturing, what truly determines quality stability, tooling life, cost efficiency, and lead-time reliability is engineering. Inside our factory, engineering is the core engine behind every project. IEC Mould don’t simply produce parts — we help customers minimize risk, reduce cost, ensure quality, and accelerate time-to-market.

Our engineering system covers the entire product lifecycle:

- DFM Engineering

- Quality Engineering

- Project Engineering

- Material Engineering

- Moldflow Simulation

- Process Engineering

- Value & Cost Engineering

- Die Casting Tooling Engineering

Why Engineering Matters in Die Casting?

Industry research shows that over 70% of die casting defects — porosity, shrinkage, deformation, cracking, warpage, dimensional instability — originate from engineering mistakes, not production issues. IEC Mould Strong Casting engineering can help you:

Avoid design-related failures and redesign cost

Early DFM and Moldflow help eliminate hidden risks such as wall thickness issues, flow imbalance, and tolerance conflicts. You avoid redesign loops, shorten development time, and ensure the part is ready for mass production.

Reduce tooling risk and extend tooling life

Optimized gating, cooling, and steel selection make the mold more stable and durable. This reduces early wear, minimizes repairs, and ensures consistent output across the tool’s lifetime.

Increase yield and reduce scrap rate

Correct engineering eliminates porosity, shrinkage, cold shuts, and thermal defects before production begins. With a clean, balanced filling and cooling design, your FPY increases and waste drops dramatically.

Shorten validation cycles

A well-engineered mold reaches dimensional stability faster. Fewer tooling adjustments are needed, helping you move through EVT/DVT/PVT in a much shorter time.

Improve supply chain stability

Strong engineering creates a wide, stable process window that remains consistent across machines, shifts, and suppliers. Your production stays predictable, reducing quality drift and supply chain disruptions.

Improve supply chain stability

Strong engineering creates a wide, stable process window that remains consistent across machines, shifts, and suppliers. Your production stays predictable, reducing quality drift and supply chain disruptions.

Why Our Die Casting Die Engineering Team Is Trusted by Global Customers?

To support demanding projects in automotive, industrial equipment, telecom, EV charging, lighting, and consumer electronics, we have built a robust in-house engineering system.

- 20+ years of experience in die casting & tooling engineering

- 15+ engineering experts (DFM, Moldflow, tooling, process, quality, PM)

- Full in-house capacity: DFM → Moldflow → Tooling → Die Casting → Machining → Finishing → Assembly

- Delivered 300–400 sets of die casting tools every year

- 90T–1500T die casting machines for complete production validation

- Automotive-level engineering processes (APQP, PPAP, FMEA, SPC, MSA)

- Supporting high-demand industries globally

- IATF 16949 / ISO9001 quality system

Casting Die DFM Engineering — Design for Manufacturability

We provide a fully documented DFM analysis for every drawing to identify all manufacturability and casting risks before tooling begins, helping customers prevent redesign and tooling rework, reduce overall production costs, accelerate the transition from design to T0 samples, ensure the part is fully ready for stable mass production, and minimize long-term quality and reliability risks.

Draft Angle & Ejection Feasibility

- Required draft for cavities and cores

- Analysis of deep ribs and small pockets

- Ejector pin layout feasibility

Wall Thickness Optimization

- Uniformity review

- Thin-wall feasibility

- Reinforcement rib suggestions

- Cooling and solidification effects

Parting Line & Tooling Constraints

- Optimal parting line selection

- Flash risk analysis

- Impact on A/B surface appearance

Shrinkage & Warpage Analysis

- Alloy-specific shrinkage prediction

- High-risk deformation zones

- Structural compensation recommendations

Cooling & Slide/Core Feasibility

- Cooling path complexity

- Slide direction conflicts

- Undercut detection

Functional Requirements Alignment

- Mechanical strength

- Thermal performance

- Assembly compatibility

- Lifetime requirement vs. alloy selection

Surface Requirement Feasibility

- Surface roughness vs. mold steel

- Texture/painting/anodizing suitability

- Cosmetic gate/overflow considerations

Tolerance Stack-Up & Machining Allowance

- Functional tolerance evaluation

- Machining datum recommendations

- CNC feasibility

- Cost impact vs. tolerance requirements

Casting Parts Moldflow Simulation — Predict Problems Before They Occur

We use advanced Moldflow simulation to evaluate flow, solidification, cooling, temperature distribution, vacuum effectiveness, and defect formation.

Moldflow Helps Prevent

- Short shots

- Porosity and shrinkage

- Cold shuts / flow lines

- Hot spots causing short tooling life

- Warpage and internal stress

- Uneven cooling → longer cycle time

Customer Gains

✔ Predict defects before the mold is built

✔ Minimize mold corrections (T0 → T1 → T2)

✔ Improve first-shot success rate

✔ Increase production stability

Die Tooling Engineering — Precision Die Casting Mold Design

The die is the soul of die casting. Our tooling engineering team designs molds that are durable, stable, easy to maintain, and built for high-volume production. What We Do in Tooling Engineering

- Parting line and cavity design optimization

- Gating & runner system optimization

- Overflow & venting system engineering

- Vacuum system design

- Cooling system simulation & layout

- High-strength slider/core-pulling mechanism design

- Heat treatment specification for mold steel

- Mold thermal balance planning

- Maintenance-friendly mold structure design

Customer Benefits

✔ Longer mold life

✔ More stable production

✔ Reduced downtime and maintenance cost

✔ Faster cycle time → lower cost per part

Die Casting Process Engineering — Stable Production Comes From Process Control

Every die casting machine setting is backed by scientific engineering. Our Casting Process Engineering Includes

- Alloy melting temperature control

- Material composition & refining process

- Mold temperature control strategy

- Injection speed curve optimization

- Intensification pressure & holding time design

- Spray cycle optimization

- Cooling timing strategy

- Vacuum parameter & venting system control

- Deburring, heat treatment, machining process planning

Our Customer Benefits

✔ Lower scrap rate

✔ Less production fluctuation

✔ Lower energy consumption

✔ Stable long-term supply

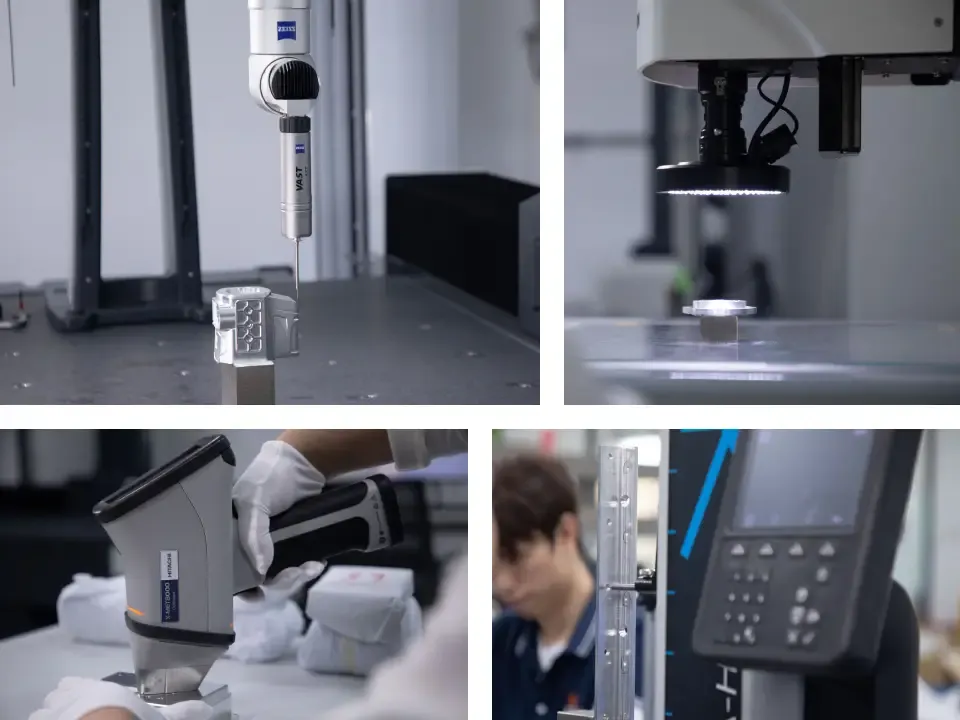

Casting Die Parts Quality Engineering — Accuracy, Consistency & Traceability

Quality engineering is not just inspection — it is the foundation of producing stable, high-performing die cast die parts. Our comprehensive quality engineering system prevents problems before they happen, controls every critical parameter, and ensures your products run smoothly from prototype to mass production.

Our Die Casting Part Quality Engineering Capabilities:

- APQP / PPAP

- PFMEA & DFMEA

- SPC (Critical dimension trend analysis)

- MSA (Gauge R&R)

- First Article Inspection

- CPK / Process Capability validation

- 8D root-cause analysis

Inspection Equipment:

- CMM 3D measurement

- 2.5D optical inspection

- X-ray inspection

- Spectrometer

- Roughness tester

- Hardness tester

- Ultrasonic thickness tester

Our Customer Benefits:

Die Casting Cost & Value Engineering — Reduce Cost Without Compromising Quality

As a die casting manufacturer serving cost-sensitive and competitive industries, we understand the constant pressure to reduce cost while maintaining performance and reliability. Our Cost & Value Engineering approach systematically identifies optimization opportunities across design, tooling, and production to help you achieve real, measurable cost-down.

What We Optimize:

- Improve yield to reduce cost-per-piece

- Replace cost-heavy surface treatments

- Gating/overflow system to improve yield

- Geometry structure for lower material usage

- Cycle time reduction via tooling improvements

- Machining time reduction through process redesign

Our Customer Gains:

- Lower BOM cost

- Lower project cost

- Faster development

- Higher competitiveness

Die Casting Material Engineering — Select the Right Alloy for Performance, Cost, and Reliability

Choosing the correct alloy is one of the most important engineering decisions in die casting. The right material determines the part’s strength, stability, durability, surface quality, and overall cost. Our material engineering team helps customers evaluate and select the optimal aluminum, zinc, or magnesium alloy based on actual application, load conditions, environmental exposure, and cost targets.

What Our Material Engineering Covers:

- Mechanical property and strength requirement evaluation

- Thermal behavior & heat dissipation analysis

- Fluidity and filling performance assessment

- Heat-treatment compatibility and performance boosting options

- Corrosion resistance and surface durability analysis

- Environmental and operating condition assessment (temperature, load, humidity, vibration)

Supported Die Casting Materials:

- Zinc: Zamak 2 / 3 / 5 / 7

- Aluminum: ADC12, A380, A383, A360, EN AC series

- Magnesium: AZ91D, AM60B, and other specialty alloys

Our Customer Benefits:

- Better performance with the right alloy for the application

- Lower material and production cost through smarter alloy selection

- Reduced risk of cracking, deformation, porosity, or long-term failures

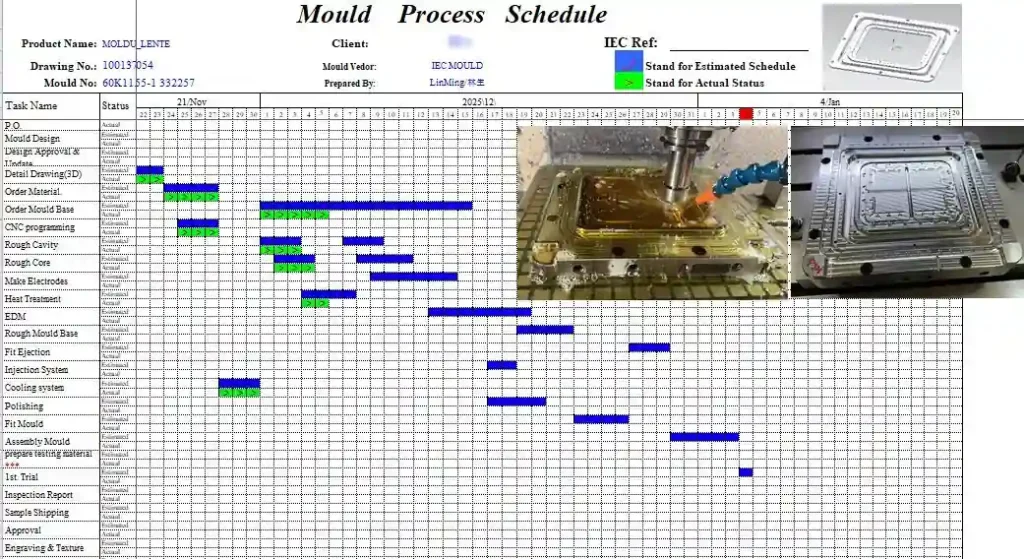

Die Casting Project Engineering — Complete Project Control

Every die casting project is assigned a dedicated Project Engineer (PM) who serves as our customer single point of contact. Our PMs provide seamless project coordination, engineering oversight, and risk management, ensuring that every design, tooling trial, and process change is meticulously tracked. With professional die casting project management, you gain transparent communication, predictable schedules, and consistent production quality, reducing the risk of delays, defects, or unexpected costs.

PM Responsibilities:

- Centralized file control for drawings, BOMs, and revisions

- Weekly progress updates to keep all stakeholders informed

- Engineering change control (ECN/ECR) to minimize design and tooling risks

- Tooling trial supervision to ensure first-shot success

- End-to-end process management: EVT → DVT → PVT → SOP

- Direct communication & technical support as your single point of contact

What Our Material Engineering Covers:

- Mechanical property and strength requirement evaluation

- Thermal behavior & heat dissipation analysis

- Fluidity and filling performance assessment

- Heat-treatment compatibility and performance boosting options

- Corrosion resistance and surface durability analysis

- Environmental and operating condition assessment (temperature, load, humidity, vibration)

Our Customer Benefits:

- Faster time-to-market

- Reduced tooling and production risk

- Higher first-pass yield & lower project cost

- On-time delivery with predictable schedules

- Peace of mind knowing every step is monitored by an expert

- Zero communication gaps — one PM manages all project details

- Full transparency & accountability throughout development and production

Interested in starting your die casting journey?

Our engineers are here to answer your questions and show you how innovative die casting technologies can revolutionize your next project.