Brushing Services for Die Cast Parts

Brushing (also called brushed finishing or linear grain finishing) is an effective surface finishing process for die cast components when controlled texture, directional grain, and premium surface aesthetic are required—without excessive cosmetic cost.

We provide precision brushing services specifically optimized for aluminum and zinc die cast parts, helping customers achieve stable visual textures, reduce the visibility of minor surface defects, and prepare parts for downstream finishing such as anodizing, powder coating, and clear coating.

- Consistent linear or circular grain

- Compatible with anodizing & coating

- Improved surface aesthetics & touch feel

- Helps mask minor cosmetic casting marks

What Is Brushed finishing?

Brushed is a mechanical finishing technique that uses abrasive belts, wheels, or pads to create a controlled, directional texture on metal surfaces. On aluminum and zinc die cast components, the process produces a uniform matte appearance with visible grain lines, reduced surface glare, and an enhanced tactile feel—without applying coatings or altering critical dimensional features.

As a die casting manufacturer, we manage brushing in coordination with casting quality to achieve stable and repeatable surface effects. Alloy characteristics, casting defects, and part geometry can influence the final brushed pattern, making surface preparation, tool selection, and grain direction control essential for consistent results.

Unlike polishing or high-gloss finishing, brushing delivers a premium metallic look that is subtle, functional, and highly compatible with downstream finishes such as anodizing, clear coats, powder coating, and plating. This makes brushed finishing well-suited for consumer-facing housings, appliance hardware, automotive interior trims, and other visible die cast components where appearance consistency, production repeatability, and brand quality are important.

Why Brushing Is Widely Used for Die Cast Parts

Liquid painting is one of the most commonly selected finishes for die casting due to its flexible color options, decorative finishes, and visual consistency, while remaining cost-efficient and suitable for design-driven components.

Key Advantages

- Produces a consistent grain pattern with controlled directionality

- Enhances surface appearance and perceived product quality

- Reduces visibility of minor cosmetic casting marks and tooling lines

- Improves tactile feel and reduces surface glare for user-facing components

Engineering Reality:

Brushing is more than a cosmetic process—it requires controlled tooling and preparation. Alloy behavior, surface defects, and part geometry affect the final grain pattern. Abrasive type, grit size, and feed direction must be managed to achieve uniform texture across batches.

Our Integrated Approach:

With in-house brushing for die cast parts, we align casting quality, surface prep, and brushing parameters under one system. This ensures consistent grain direction and downstream compatibility for consumer electronics, appliances, lighting, and automotive components.

Brushing for Die Cast Parts Manufacturing Advantage

Most brushing challenges don’t occur at the brushing machine—they originate during die casting. When casting and brushing are performed by different suppliers, surface defects, alloy inconsistencies, and uncontrolled handling can lead to uneven grain patterns, visible tool marks, and poor batch uniformity. By integrating die casting and brushing in one facility, these issues are eliminated at the source.

- Die casting parameters are managed to reduce surface blemishes before brushing

- Parts enter finishing without transport-related scratches or oxidation

- Casting and brushing teams coordinate on surface prep and grain direction

- Each production batch follows a controlled flow from casting to finished texture

The result is not just a brushed appearance, but a clean, uniform metallic grain that holds up in mass production—rather than a superficial texture applied over inconsistent cast surfaces.

Brushing for Suitable Casting Materials

Brushing is particularly effective on aluminum and zinc die cast parts, producing a controlled metallic texture with consistent grain patterns and a refined matte appearance. Not all alloys behave the same under brushing, so proper alloy selection and surface preparation are essential to achieve uniform results. Common die casting alloys suitable for brushing include:

ADC12

Widely used for consumer and industrial products; provides stable grain texture with moderate visual refinement.

A380

Common in functional components; allows predictable linear or circular grain patterns.

A360

Lower silicon content improves uniformity and consistency of brushed texture.

Zamak 3 / 5

Fine-grain structure produces smooth, even brushed surfaces; suitable for decorative hardware and small precision components.

⚠️ Note: Brushing is not generally suitable for ferrous die castings or plastic parts. Alloy composition, part geometry, and surface quality must be carefully evaluated to ensure consistent grain direction, uniform texture, and repeatable results across production batches.

How Our Brushing Die Casting Process Works — Step by Step

Our brushing process is fully integrated with die casting to ensure uniform, high-quality surface textures. Each stage is carefully controlled to manage alloy behavior, surface condition, and part geometry, delivering consistent and repeatable brushed finishes.

Casting Preparation

Die cast parts are inspected for surface blemishes, porosity, and alloy suitability. Critical areas are checked to ensure the final brushed grain will form evenly and consistently.

Surface Preparation

Parts are thoroughly cleaned to remove oils, release agents, and other contaminants. Pre-treatment and light deburring help create a smooth base for controlled brushing.

Brushing Process

Using precision abrasives and controlled feed direction, parts are brushed to achieve the desired linear, circular, or non-directional grain. Grit selection, speed, and pressure are adjusted for uniform texture and appearance.

Optional Finishing

After anodizing, parts undergo sealing to enhance corrosion resistance and surface stability. Optional coloring or post-treatment can be applied depending on alloy and specification requirements.

Quality Inspection

Each batch is inspected for grain uniformity, surface smoothness, and visual consistency. Controlled workflows ensure repeatable finishes across production runs.

The result is a durable, functional, and visually appealing brushed finish that enhances product aesthetics, tactile feel, and perceived quality—without masking underlying casting issues.

Surface Preparation — The Key to Uniform Brushed Finishes

For brushing, the final appearance is just what you see on the surface. What truly ensures consistent grain, uniform texture, and a premium metallic look happens before the abrasive even touches the part. On aluminum and zinc die cast components, proper surface preparation determines how well the brushed pattern forms and how repeatable it will be across production batches.

Common Industry Challenges

Die cast parts often present subtle issues that can compromise brushed finishes:

- Micro-porosity or surface unevenness can lead to irregular grain patterns

- Residual oils, mold release agents, or debris may create streaks or inconsistent texture

- Alloy composition, casting geometry, and corner details can affect grain direction and depth

These issues are not always visible on raw castings and often only appear after brushing, making rework costly and aesthetics inconsistent.

Our Control Measures

To achieve reliable, repeatable brushed finishes, we focus on preparing the surface, not just the act of brushing itself:

- Surface conditioning tailored for uniform grain and smooth texture

- Cleaning and deburring that accounts for porosity and surface defects

- Adjustments for sensitive alloys to ensure even texture formation

- Careful masking for functional or decorative areas requiring precise grain direction

By controlling these factors, our brushing process delivers consistent, high-quality metallic textures that look premium, feel smooth to the touch, and maintain uniformity across every production batch.

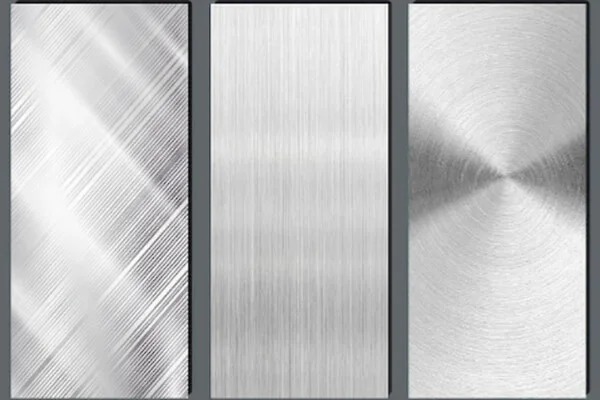

Brushing Options for Die Cast Parts We Offer

We provide a variety of brushing finishes specifically designed for aluminum and zinc die cast components, delivering consistent grain patterns, enhanced surface aesthetics, and functional texture. Each option is selected based on alloy, part geometry, and application requirements to ensure predictable and repeatable results.

Linear Grain Brushing

— Straight, directional lines that give a clean, modern metallic appearance; ideal for appliance hardware, electronics, and visible housings.

Circular Grain Brushing

— Smooth, radial texture for components with curved or rounded surfaces; enhances visual depth and reduces glare.

Non-Directional / Random Grain Brushing

— Subtle, irregular patterns that help mask minor surface imperfections and provide a matte, uniform look across complex geometries.

Combined or Custom Grain Finishes

— Tailored patterns for functional or decorative purposes; process parameters adjusted to maintain consistent texture across batch production.

⚠️ Note: Extremely high-gloss or mirror-like brushing is generally not recommended for die cast parts due to micro-porosity and alloy structure, which can cause uneven grain or streaks. Each brushing type is carefully executed to maintain surface uniformity, consistent grain direction, and repeatable aesthetics across production runs, ensuring both functional reliability and premium appearance.

Custom Brushed Finishes for Die Cast Parts

Brushing Capabilities & Surface Options

Brushing is a precision mechanical finishing process that creates controlled directional textures on aluminum and zinc die cast surfaces. It enhances appearance, tactile feel, and functional surface quality without adding coatings or altering critical dimensions.

Precisely managed brushing parameters—including abrasive type, grit size, and feed direction—ensure consistent linear, circular, or custom grain patterns across production batches.

Brushed surfaces are compatible with downstream treatments such as clear coating, powder coating, or anodizing, and maintain uniform texture for functional or decorative components.

Uniform surface roughness and tactile feel provide a premium look while masking minor casting imperfections.

Improved surface smoothness, reduced glare, and enhanced metallic aesthetics compared to as-cast surfaces.

Key Technical Control & Quality Focus

By integrating die casting and brushing under a single controlled workflow, we manage alloy behavior, surface condition, and process parameters as a unified system. This ensures stable grain formation, consistent appearance, and repeatable results from batch to batch.

Brushing parameters are optimized to avoid deformation or material removal that could affect critical dimensions.

Abrasive materials and process methods are selected to meet safety, environmental, and regulatory requirements, ensuring industrial-grade reliability.

Brushing speed, pressure, and grit selection are tuned according to alloy type, part geometry, and desired texture.

Grain direction, texture depth, and visual consistency are checked for each batch.

Design Guidelines for Brushed Die Cast Parts

The quality of a brushed finish is determined long before the part reaches the brushing machine. For aluminum and zinc die cast components, surface geometry, alloy characteristics, and dimensional consistency directly influence grain uniformity, texture depth, and overall visual quality. Unlike coatings or plating, brushing modifies the existing metal surface, so design choices made during the die casting stage significantly affect the consistency and appearance of the final finish.

To achieve uniform brushed finishes on die cast parts, we recommend:

- Avoiding sharp corners, thin walls, or sudden section changes that can cause irregular grain formation or inconsistent texture

- Designing balanced wall thickness and smooth transitions to support even abrasive contact during brushing

- Defining visible and functional surfaces early, especially when precise grain direction or selective brushing is required

- Maintaining consistent as-cast surface quality to minimize variation in grain pattern, depth, and appearance

By aligning die casting design with brushing behavior, brushed die cast parts achieve consistent grain patterns, uniform surface aesthetics, and repeatable tactile quality—without relying on corrective processing or excessive post-treatment.

While brushing delivers controlled grain patterns and premium metallic texture, not all die cast features are equally suitable for this surface finish. Certain geometries, alloy behaviors, and functional requirements should be carefully evaluated during design.

- Tight-tolerance interfaces where material removal or abrasive contact could affect fit, alignment, or assembly clearance

- Precision-machined surfaces that require exact dimensions and cannot tolerate the slight material displacement caused by brushing

- Deep recesses, narrow cavities, or complex internal features where consistent grain formation is difficult to achieve

- Parts with sensitive or mixed alloys that may result in uneven texture or irregular grain patterns

In these situations, selective brushing, masking, or alternative surface treatments such as anodizing, powder coating, or plating may provide more predictable aesthetics and functional performance than full-surface brushing.

We provide DFM-focused engineering support for aluminum and zinc die casting projects at the quotation stage, emphasizing brushing feasibility and desired surface texture.

Our engineers evaluate part geometry, visible and functional surfaces, alloy properties, and dimensional tolerances to determine whether full-surface brushing, selective brushing, or alternative finishing methods will deliver consistent, high-quality metallic textures — all before production begins.

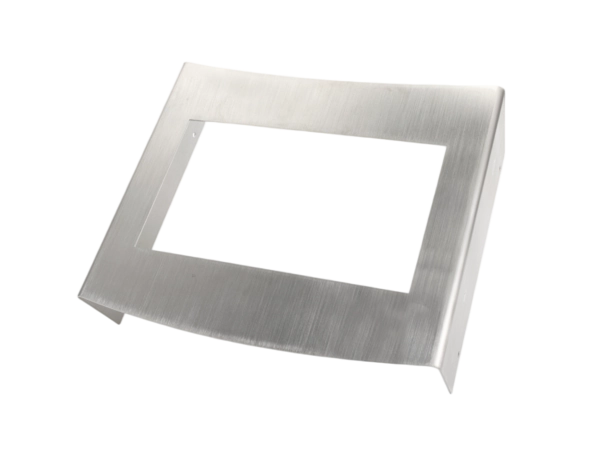

Ideal Industries & Products for Brushed Die Cast Finishes

Automotive Interiors & Decorative Trim

– Dashboard bezels, center console panels, air vent surrounds, door handles

Consumer Electronics

– – Laptop casings, tablet frames, smartphone enclosures, smart home devices

Industrial Equipment & Control Panels

– Switch panels, control housings, machine covers

Home Appliances & Kitchen Hardware

– Refrigerator panels, oven handles, range hood components, faucets, cabinet hardware

Lighting Fixtures & Architectural Components

– LED housings, chandeliers, wall sconces, metal trim elements

Furniture & Decorative Metal Fittings

– Handles, brackets, knobs, accent pieces

Our 6 Quality Controls for Brushed Die Cast Parts

Consistent brushed finishes rely on systematic inspection and process management, focusing on grain uniformity, texture depth, and surface consistency.

- Incoming Casting Inspection – Check as-cast surfaces for porosity, blemishes, and alloy suitability to ensure an ideal base for brushing.

- Surface Preparation Verification – Confirm cleaning, deburring, and pre-treatment steps are properly executed to support uniform grain formation.

- Brushing Process Control – Monitor abrasive type, grit size, feed direction, speed, and pressure to maintain consistent texture and appearance.

- Texture & Grain Assessment – Evaluate grain pattern, depth, and directionality to ensure repeatable surface aesthetics across batches.

- Visual & Tactile Evaluation – Inspect uniformity of finish, metallic look, and tactile feel for consumer-facing and functional surfaces.

- Batch Traceability – Maintain detailed records of casting, preparation, and brushing parameters for predictable results from prototypes to full-scale production.

Why Brushing Can Be Challenging on Die Cast Parts — How We Control It

Brushing defects often originate from the die cast substrate rather than the finishing process itself. Surface porosity, uneven geometry, or alloy variations can lead to irregular grain patterns, inconsistent texture depth, or uneven visual appearance. By integrating die casting with brushing, we address potential issues proactively, rather than correcting them after finishing.

| What Customers Might See | Why This Happens on Die Cast Parts | How We Prevent It in Production |

|---|---|---|

| Inconsistent Grain Pattern | Surface micro-porosity, rough spots, or thin walls | Controlled surface prep, porosity-aware cleaning, and precise brushing parameters |

| Uneven Texture Depth | Alloy composition differences or uneven abrasive contact | Batch-controlled process, proper grit selection, and optimized feed direction |

| Directional Grain Misalignment | Complex geometry, sharp corners, or recessed areas | Design guidance, selective masking, and controlled brushing angles |

| Surface Streaks or Marks | Residual debris, release agents, or inconsistent pre-treatment | Standardized cleaning and deburring protocols, with batch inspection |

| Edge or Corner Irregularities | Abrasive contact uneven at corners or tight features | Rounded edge design, selective brushing, and focused process control |

| Surface Contamination | Oils, particles, or improper handling | Thorough degreasing, inspection, and careful handling before brushing |

Surface Finishing Comparison for Die Cast Parts: Brushing, Powder Coating & Anodizing

Different finishing methods offer unique advantages depending on visual requirements, functional needs, and production scale. Understanding these differences helps engineers, procurement, and quality teams choose the optimal process for die cast components.

| Feature / Consideration | Brushing | Powder Coating | Anodizing |

|---|---|---|---|

| Material Compatibility | Aluminum, zinc; works on most non-ferrous alloys | Aluminum, zinc, magnesium; industrial durability | Aluminum only; sensitive to porosity |

| Surface Texture / Layer | Creates directional metallic grain; no added coating | Thick protective layer; uniform coverage | Thin, integral oxide layer |

| Edge & Corner Performance | Grain may vary on sharp corners or recessed areas | Full coverage on complex geometries | Can be uneven on tight edges or high-silicon areas |

| Appearance Consistency | Controlled directional or custom grain; premium metallic look | Uniform color and texture; limited texture effects | Consistent metallic or dyed tones; limited palette |

| Complex Geometry Suitability | Best for visible, flat, or gently contoured surfaces | Excellent for intricate parts and full coverage | Challenging for complex shapes or deep recesses |

| Production Volume | Low to medium; ideal for consumer-facing or decorative components | Medium to high; suited for industrial-scale production | Low to medium; functional aluminum parts |

| Design & Branding Flexibility | High; grain orientation and pattern can be customized | Moderate; mainly uniform finish | Limited to metallic or dyed finishes |

Key Takeaway

Brushing is ideal for die cast parts where premium metallic aesthetics, tactile feel, and controlled texture are the priority. Powder coating delivers high-volume, protective coverage for functional surfaces. Anodizing is best for aluminum parts requiring durable, wear-resistant, or metallic finishes with controlled surface properties.

Why Customers Choose IEC Mould for Their Brushed Die Cast Parts

At IEC Mould, we deliver consistent, high-quality brushed aluminum and zinc die cast components designed to meet both aesthetic and functional requirements for global projects.

- Engineering-driven brushing: Our integrated approach ensures uniform grain patterns, controlled texture depth, and repeatable tactile quality—even for prototypes or low-volume production.

- Complete in-house process control: From die casting and surface preparation to brushing and optional downstream coatings, every step is monitored to guarantee consistent texture, appearance, and surface performance.

- Flexible finishing options: We provide linear, circular, non-directional, or custom grain patterns, with selective brushing available for functional or decorative areas.

- Proven global expertise: Our combined die casting and brushing experience has delivered premium, reliable parts for clients across consumer electronics, home appliances, automotive interiors, lighting, furniture hardware, and industrial applications.

Start Your Brushed Die Casting Project

Reach out to our engineering team to discuss your application, part design, and brushing finish requirements.

Our experts collaborate with you to ensure consistent grain patterns, uniform texture, and premium metallic appearance—helping your die cast parts achieve the perfect look and feel, without surprises.