Choosing the wrong aluminum alloy for die casting can lead to costly failures, delayed timelines, and underperforming products. With numerous options available, how do you pick the right one for your specific die casting project? This comprehensive guide will demystify the selection process, comparing key alloys and providing a clear framework to help you make an informed, optimal decision for performance, cost, and manufacturability.

Why Aluminum Reigns Supreme in Die Casting

Aluminum alloys offer an ideal balance of properties for high-volume production. Their lightweight strength, excellent corrosion resistance, and superior castability make them the top choice. When selecting an aluminum alloy for die casting project, these inherent advantages provide a strong starting point.

| Property | Description |

|---|---|

| Lightweight Strength | Aluminum provides an exceptional strength-to-weight ratio. Components can be strong and rigid while significantly reducing overall product weight—a critical factor in automotive and aerospace applications for fuel efficiency and performance. |

| Superior Corrosion Resistance | A natural oxide layer forms on aluminum, providing excellent resistance to corrosion. This makes it suitable for components exposed to harsh environments, from outdoor enclosures to under-the-hood automotive parts. |

| Excellent Castability | Aluminum alloys melt at a lower temperature than many metals, reducing energy consumption and wear on tooling. Their excellent fluidity allows them to fill intricate molds and produce thin-walled, complex geometries with high dimensional accuracy. |

| High Thermal & Electrical Conductivity | Aluminum efficiently dissipates heat and electricity, making it the material of choice for heat sinks, LED housings, and electrical components. |

| Sustainability Champion | Aluminum is 100% recyclable without loss of its inherent properties. Using recycled aluminum in die casting (often with high post-consumer content) significantly reduces the carbon footprint, aligning with green manufacturing initiatives. |

Key Properties to Evaluate in a Die Cast Aluminum Alloy

Not all alloys perform the same. Understanding these core properties is crucial when evaluating an aluminum alloy for die casting applications:

| Performance Category | Key Properties & Description |

|---|---|

| Mechanical Properties | Tensile Strength (resistance to pulling apart), Yield Strength (point of permanent deformation), and Elongation (ductility). Higher strength often comes with reduced ductility. |

| Physical Properties | Density (weight), Thermal Expansion Coefficient (dimensional change with temperature), and Thermal Conductivity (heat dissipation ability). |

| Process Properties | Fluidity (ability to fill thin sections of a mold), Hot Tearing Resistance (susceptibility to cracking as it solidifies), and Die Soldering Tendency (sticking to the steel mold). |

| Post-Processing Performance | Machinability (ease of drilling, tapping, milling), Polishing & Plating potential, and Anodizing Response (for aesthetic or corrosive-resistant surface finishes). |

Comparison of Major Die Cast Aluminum Alloys

The following table compares the most common aluminum alloys for die casting, highlighting their distinct roles.

| Alloy Designation (Common Standards) | Key Composition & Characteristics | Primary Advantages | Ideal Application Examples | Cost & Considerations |

|---|---|---|---|---|

| ADC12 (A383) | High Silicon (~10-12%), Good Copper content. | Excellent castability and fluidity, good resistance to hot tearing, pressure-tight. | Automotive components (transmission cases, valve bodies), engine brackets, electronic housings. | The most common and cost-effective general-purpose alloy. Excellent balance. |

| A380 | Balanced Silicon (~8.5%) and Copper (~3.5%). | The industry benchmark. Excellent combination of strength, fluidity, and machinability. | Power tools, lawnmower housings, gearboxes, structural automotive parts. | Slightly higher strength than ADC12, excellent all-rounder. Widely available. |

| ADC10 (A380 Variant) | Similar to A380 with slightly lower copper. | Better corrosion resistance than standard A380 while retaining good strength. | Parts for marine environments, decorative hardware, applications where corrosion is a concern. | Moderate cost. A good choice when corrosion resistance is a priority. |

| AlSi9Mg (A360) | High Silicon (~9%), with added Magnesium. | Superior strength and ductility (elongation). Excellent for heat treatment (T5, T6). | High-integrity structural parts, automotive safety components, bicycle frames, parts requiring high pressure tightness. | Higher cost due to magnesium content and often slower casting speed. Used when mechanical performance is critical. |

| AlSi12 (A413) | Very High Silicon (~12%), low impurity levels. | The best fluidity and dimensional stability. Excellent resistance to hot cracking. | Complex, thin-walled castings (electronic enclosures, laptop chassis), parts with intricate details. | Excellent for difficult-to-fill molds. May be slightly less strong than lower-silicon alloys. |

How to Choose: A Scenario-Based Decision Guide

Match your project’s primary requirements with these recommendations:

| Application Requirement | Recommended Alloy | Key Advantage |

|---|---|---|

| Maximum Strength & Ductility | A360 (AlSi9Mg) | Best response to heat treatment (T6 temper) for highest mechanical properties; ideal for structural/safety-critical parts |

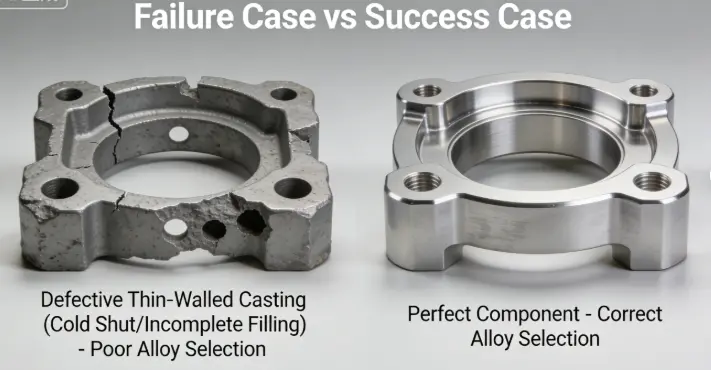

| Complex, Thin-Wall Designs | ADC12 (A383) or A413 (AlSi12) | High silicon content provides superior fluidity to fill intricate molds without defects |

| Excellent Machinability | A380 or ADC12 | Faster machining speeds, better chip breakage, longer tool life, reducing secondary processing costs |

| Cost-Sensitive, High-Volume Production | ADC12 or A380 | Excellent castability leads to faster cycle times, high yield rates, lower overall part cost; industry workhorses |

| Superior Corrosion Resistance or Anodizing | ADC10 or “anodizing grade” (low-copper alloy) | High copper content causes discoloration and reduced corrosion performance; low-copper alloys avoid this issue |

Other Critical Factors for Success

The alloy designation is just the start. Final part performance is equally influenced by:

Melt Quality: Control of hydrogen gas and oxide inclusions is crucial for porosity and integrity. A reputable die caster will have rigorous melt handling procedures.

Die Design & Cooling: The mold design dictates how the alloy solidifies. Proper gating and cooling channels are essential to achieve sound microstructure and minimize defects.

Process Parameters: Injection speed, pressure, and temperature profiles must be optimized for the specific alloy and part geometry.

Heat Treatment (Temper): Applying T5 (aged) or T6 (solution treated and aged) temper can dramatically increase the strength of suitable alloys like A360.

Common Pitfalls and Expert Advice

Pitfall 1: Selecting an Alloy in a Vacuum. The “best” alloy depends on your die caster’s expertise and equipment. Some foundries specialize in certain alloys.

Pitfall 2: Over-Engineering. Don’t specify a high-performance, expensive alloy like A360 if a standard A380 will functionally suffice. It unnecessarily increases cost.

Pitfall 3: Ignoring the Total Cost. Consider the entire process: raw material cost, castability (yield and cycle time), machinability, and finishing.

Expert Advice: Collaborate Early. Engage with your die casting partner during the design phase. They can advise on alloy selection, design for manufacturability (DFM), and potential trade-offs to optimize for performance and cost.

Future Trends: Emerging Alloys and Sustainability

High-Thermal-Conductivity Alloys: Driven by electric vehicles and advanced electronics, new alloys are being developed to better manage heat in battery trays and power modules.

Enhanced Recycled-Content Alloys: Advanced sorting and refining technologies are enabling the use of higher percentages of post-consumer recycled aluminum without compromising critical properties.

Digital Integration: Alloy property databases and simulation software are increasingly used to predict how a specific alloy will behave in a virtual mold, reducing trial and error.

Conclusion and Your Action Plan

The “best” aluminum alloy is the one that optimally balances your product’s performance requirements, manufacturability, and total project cost.

Your Action Plan:

Define & Prioritize: List your part’s critical needs (e.g., strength vs. corrosion resistance vs. thermal conductivity).

Consult the Experts: Share your requirements and part design with 2-3 reputable die casting specialists. Ask for their alloy recommendation and why.

Prototype & Test: If possible, produce prototypes with the top alloy contenders to validate performance in real-world conditions.

Think Long-Term: Establish a partnership with a die caster who provides transparency, quality data, and collaborates to refine material choice over the product lifecycle.