In the global manufacturing sector, Die Casting Aluminum is the benchmark for high-volume precision. However, a common pitfall for procurement managers is focusing solely on the “Unit Price”. This “Price-First” mentality often hides cascading costs that erode profit margins by up to 40%.

To achieve true ROI, you must look at the Die Casting Aluminum process holistically. This guide exposes the 7 hidden traps in the production of Die Casting Aluminum and provides actionable strategies to optimize your supply chain.

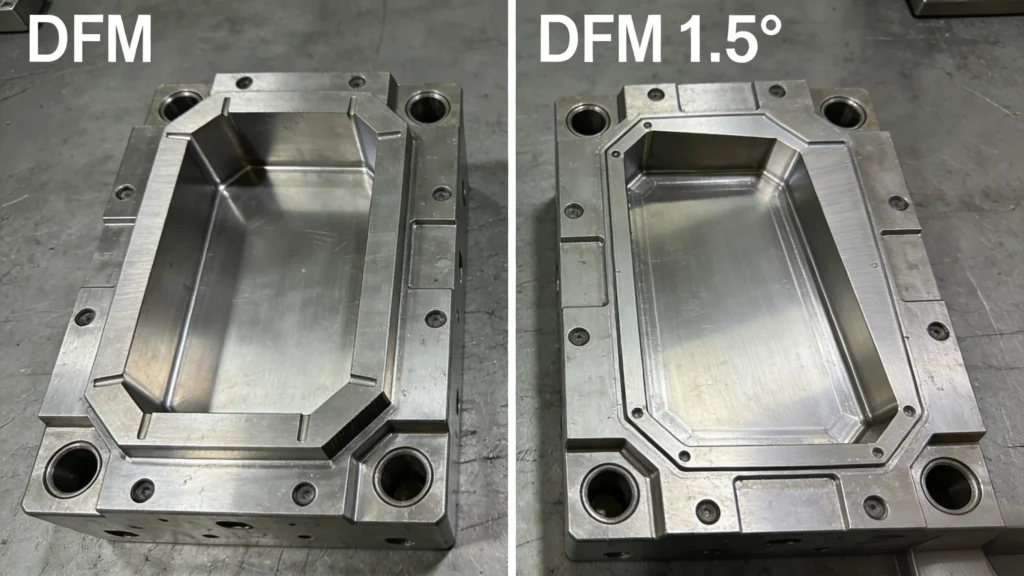

Trap 1: DFM Failure in Die Casting Aluminum

The most expensive manufacturing mistakes are solidified at the drawing board. A DFM Failure in Die Casting Aluminum mold that isn’t optimized for DFM (Design for Manufacturing) acts as a permanent tax on your production.

- The Hidden Cost: Excessive wall thickness doesn’t just waste DFM Failure in die casting aluminummaterial; it exponentially increases cycle time and risks internal casting of aluminum defects like shrinkage porosity.

- The Fix: Implement a 1.5° to 2° draft angle to ensure clean ejection from the casting dies.

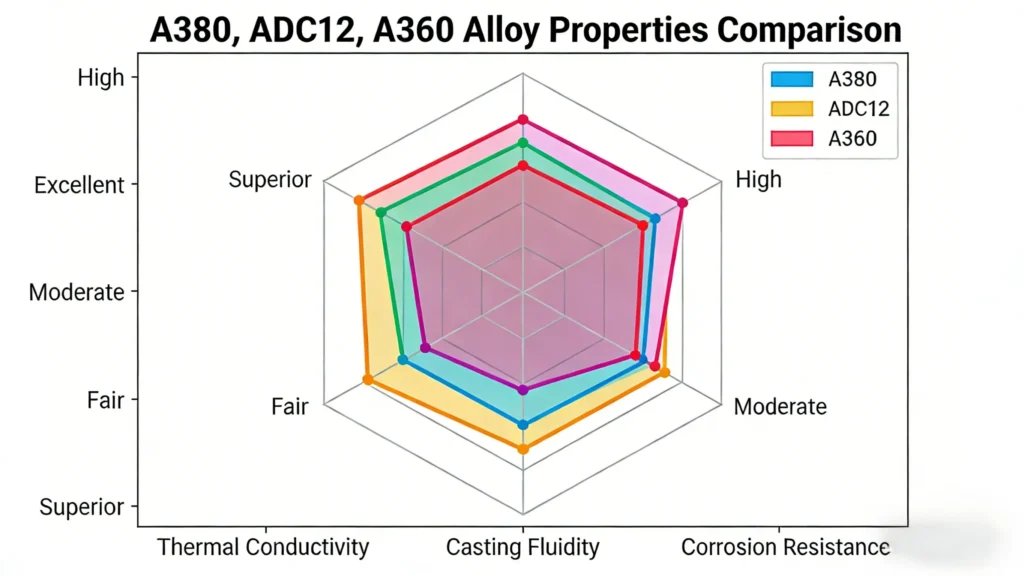

Trap 2: Alloy Misalignment (A380 vs. ADC12 vs. A360)

Many engineers default to “what we used last time”, ignoring that aluminum die casting materials dictate the rejection rate.

| Best Grade | Thermal Conductivity | Casting Fluidity | Corrosion Resistance | Best For |

|---|---|---|---|---|

| A380 | High | Excelent | Moderate | Standard for Asian Die Casting Aluminum supply chains |

| ADC12 | High | Excelent | Moderate | Standard for Asian supply chains |

| A360 | Moderate | Fair | Superior | High corrosion resistance Die Casting Aluminum |

The Trap: Using A360 for a simple bracket. It’s harder to cast and increases tool wear. Stick to die casting alloys aluminum like A380/ADC12 unless specific mechanical properties demand otherwise.

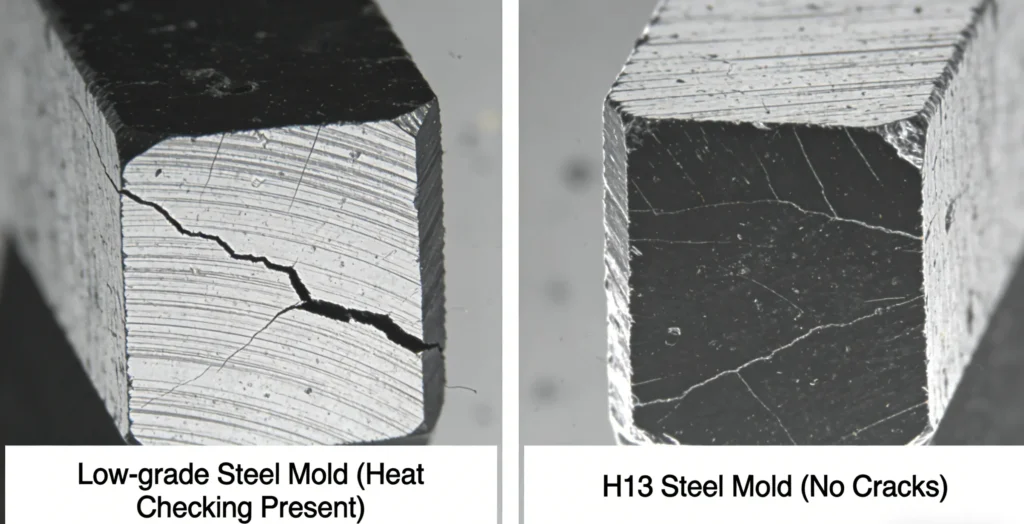

Trap 3: The "Cheap Steel" Tooling Mirage in Die Casting Aluminum

When sourcing tooling for die casting aluminum, it’s tempting to pick the lowest-priced steel option. After all, “steel is steel,” right? Wrong.

Aluminum die casting exposes tooling to extreme conditions: temperatures up to 700°C (1,292°F), high injection pressure, and repeated thermal cycling (heating/cooling). “Budget” steels (e.g., low-grade carbon steel) lack the heat resistance and hardness to withstand this stress.

The hidden costs here:

- Premature tool failure: A cheap steel tool might last 50,000 cycles—vs. 150,000+ cycles for a quality tool (e.g., H13 tool steel). This means replacing tooling 3x more often.

- Inconsistent part quality: Warped tools lead to dimensional defects, requiring 15–25% more rework or scrap.

- Downtime: Tool repairs/replacement can halt production for 1–2 weeks, delaying orders and risking customer relationships.

- The Reality: High-pressure die casting aluminum involves extreme thermal fatigue. Lower-tier steel will develop “heat checking” (surface cracks) after just 20,000 shots.

3 Steps to Skip the “Cheap Steel” Trap:

- Specify tool steel by grade (not just “steel”). Require H13 (or equivalent) tool steel for die casting aluminum—it’s engineered for high heat and pressure. Include this as a non-negotiable line item in your RFQ.

- Ask for cycle-life guarantees. A reputable caster will guarantee 100,000+ cycles for H13 tooling. If a supplier can’t commit to a minimum cycle count, walk away.

- Calculate “total tooling cost per part” (not just upfront price). Example:

◦ Budget steel: $15,000 upfront → 50,000 cycles → $0.30/part in tooling cost.

◦ Premium steel: $25,000 upfront → 150,000 cycles → $0.17/part in tooling cost.

The “expensive” option is cheaper per part in the long run.

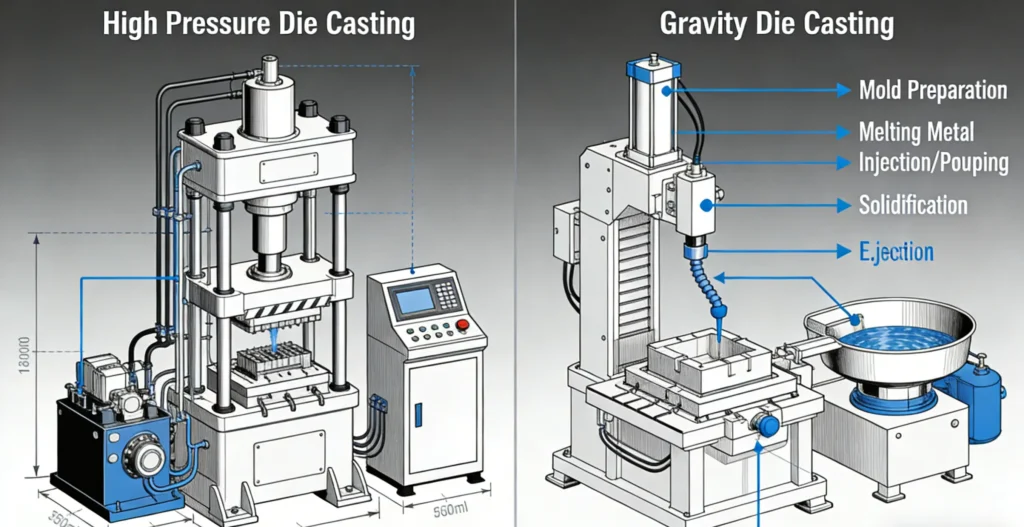

Deep Dive: High Pressure vs. Aluminium Gravity Die Casting

Choosing between aluminium high pressure die casting and aluminium gravity die casting is a critical financial decision.

- Aluminium High Pressure Die Casting: Best for complex, thin-walled die cast parts. It uses an aluminium die casting machine to inject metal at high velocity.

Aluminium Gravity Die Casting: Ideal for thicker cast aluminum parts where high-strength heat treatment is required. Understanding what is die cast aluminum in both contexts prevents over-engineering and keeps your die-casting product costs competitive.

Trap 4: Surface Finish Over-Specification

Does an internal die housing or structural component need a mirror-polish?

- The Trap: Treating every aluminium die cast surface as a “Class A” aesthetic surface.

- The Fix: Use “as-cast” finishes for internal die casting components. Only invest in premium coatings for visible die casting aluminium cookware or consumer-facing automotive aluminum die casting.

Trap 5: The CNC Machining "Crutch"

Over-reliance on secondary machining is a sign of poor die cast parts precision.

- The Trap: Designing a part with loose tolerances and “fixing it” on a CNC mill.

- Pro Tip: Modern aluminium high pressure die casting can achieve ISO 2768-m tolerances. By investing in high-precision aluminum die casting parts, you can often eliminate 80% of secondary machining labor.

Trap 6: Logistics Inefficiencies & "Shipping Air"

Logistics often account for 10-15% of the landed cost for aluminum things.

- The Trap: Bulky packaging for cast aluminum parts leads to high shipping volumes.

- The Solution: Use custom thermoformed trays. They protect the metal cast surfaces from scratches and maximize container density, lowering the final cost of your aluminium die castings.

Trap 7: Quality Blind Spots & Porosity Control

Internal porosity is the “silent killer” of basic aluminum castings.

- The Danger: If you discover air bubbles only after expensive machining, you lose both the diecast material cost and the labor time.

- Requirement: Ensure your die caster uses X-ray analysis and real-time shot monitoring. Catching defects during the aluminium die casting process is significantly cheaper than a field failure.

Future Trends: The Evolution of the Die Casting Aluminium Industry

As the aluminium die casting industry shifts toward electric vehicles (EVs), the demand for structural auto diecasting is skyrocketing. Innovations in cold cast aluminum and alloy die casting are allowing for larger, integrated components (Giga-casting). Staying ahead of these aluminum die casting process trends ensures your diecasting aluminium strategy remains future-proof.

FAQ: Strategic Sourcing for Die Casting Aluminum

What is Die Cast Aluminum?

It is a process where molten aluminum die cast material is injected into a steel mold under high pressure to create complex diecast shapes with high precision.

What is a die in casting?

A casting of aluminum requires a “die”, which is the permanent steel mold (or die cast aluminum mold) into which the molten metal is injected.

How to cast aluminum for automotive parts?

Automotive aluminum die casting typically requires high pressure aluminum die casting machines to ensure high density and strength for structural diecast aluminum components.

What is the meaning of die casting for ROI?

In a business context, the meaning of die casting is the ability to produce thousands of identical aluminum alloy die casting parts with minimal labor, maximizing scalability.

Stop Buying Parts, Start Buying Processes

The most profitable Die Casting Aluminium projects are the result of Early Supplier Involvement (ESI). By avoiding these 7 traps, you don’t just save cents—you protect your brand reputation and ensure long-term stability in the aluminium die casting industry.

Ready to de-risk your next project? Contact our engineering team for a Free DFM Audit. We will review your 3D files to identify potential cost-savings in your die casting aluminum product before you cut the steel.