One-Stop Die Casting & Precision

Manufacturing for All Industries

IEC Mould supplies die cast components to global OEM and industrial manufacturers across multiple sectors including machinery components, medical equipment, door hardware, sanitary & plumbing, pump & valve systems, lighting products, food machinery, automotive, and marine industries.

We support engineering teams, procurement departments and QC professionals from early DFM validation through tooling, mass production, CNC machining, finishing and assembly.

Casting Industries We Serve

Explore the industries we serve and discover how IEC Mould combines die casting expertise, precision machining, and finishing capabilities to meet demanding industrial requirements.

Machinery Components

Industrial machinery relies on die-cast components for structural stability, precision alignment, and long-term durability. Common applications include gear housings, brackets, covers, and machine frames. Parts require:

- Dimensional stability & strength

- Machinable datum features

- Mounting/assembly accuracy

- Impact & vibration resistance

- Surface finishing for harsh environments

Medical Equipment

Medical devices demand extremely precise tolerances, hygienic-compatible surfaces, and defect-free cosmetic finishes. Our die-cast housings, brackets, and instrument covers meet:

- Tight mechanical tolerances

- Cosmetic surface quality

- Documentation & traceability

- Low-defect finishing

- Lightweight but rigid housings

Automotive Components

The automotive and EV sectors require parts that balance strength, weight, and dimensional accuracy. Applications include motor housings, transmission cases, brackets, and heat sinks. Key requirements include:

- Thin-wall lightweight structures

- Functional sealing for oil/water

- Tight tolerances after machining

- Thermal performance

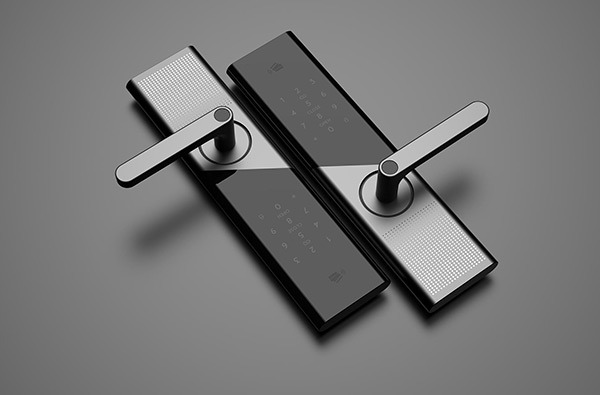

Door Hardware

Door locksets, handles, and plumbing valves require both functional and aesthetic excellence. Parts must withstand repeated use, provide corrosion resistance, and maintain smooth operation. Our die-cast solutions address:

- Decorative finishing (plating, coating)

- Wear & corrosion resistance

- Dimensional fit for moving parts

- Aesthetic consistency for visible areas

Sanitary & Plumbing

Sanitary and plumbing devices benefit from corrosion-resistant alloys and smooth finishing suitable for water environments. Parts need:

- Leak-proof and pressure resistance

- Corrosion resistance in wet environments

- Machinable sealing faces & threads

- Cosmetic surface quality

Food Machinery

Food processing equipment uses robust components with hygienic-compatible surfaces and reliable assembly fit.

- Cleanable, smooth surfaces

- Robust structures for industrial duty

- Precision interfaces for mechanisms

- Coating/plating compatibility

Lighting Products

LED and architectural lighting housings require heat dissipation, uniform coating and outdoor corrosion resistance. Parts need:

- Thermal performance

- Outdoor corrosion resistance

- Decorative powder coating

- Precision mounting interfaces

- IP sealing features

Pump & Valve Systems

Pump housings, valve bodies, fittings and hydraulic components rely on accurate internal cavities and sealing interfaces. Parts need:

- Accurate internal bores & ports

- CNC-machined sealing faces

- Pressure/leak resistance

- Corrosion protection

- Alloy compatibility with fluids

Marine & Yacht Components

Marine applications demand extreme corrosion resistance, waterproofing, and structural durability. We supply housings, brackets, and covers designed for:

- Corrosion resistance (salt/vapor exposure)

- Sealing and waterproof interfaces

- Strong mechanical structures

- UV-resistant finishing

How We Support These die casting Industries

Although performance needs vary across industries, our support framework remains consistent:

3D Printing

Rapid Prototyping

Surface finishing

Precision CNC machining

Engineering evaluation & DFM

Die Casting Mold Making

Die Casting Productions

Assembly & functional support

For detailed manufacturing capability information:

Start Your Die Casting Project

Whether you are at concept, design validation, sampling, tooling transfer, or mass production, our engineering team can support you from early evaluation through serial production.

- ENDA available

- Free DFM & MoldFlow Report

- Files accepted: STEP / STP / IGS / PDF

- Engineering feedback within 24–48 hours