In an era where efficiency and performance are paramount, magnesium die casting stands out as a key enabler of innovation. As the lightest structural metal available, magnesium alloys unlock unparalleled opportunities for weight reduction without sacrificing strength. This guide examines the process, advantages, and practical considerations of magnesium die casting, providing the insights necessary to evaluate its potential for your next project.

Why Choose Magnesium?

The viability of magnesium for die casting stems from a unique set of physical properties:

Extreme Lightweight: With a density of 1.74 g/cm³, it is 35% lighter than aluminum, 75% lighter than zinc, and 80% lighter than copper.

Property

Magnesium (Mg)

Aluminum (Al)

Zinc

(Zn)

Cooper

(Cu)

Guide

Density

1.0

1.6

4.2

5.0

Normalized to Mg density = 1.0

Excellent Castability: Low melting point and high fluidity allow for the production of complex, thin-walled components with high dimensional accuracy.

Superior Machinability: It can be machined at higher speeds with longer tool life, significantly reducing secondary operation costs.

Functional Performance: Provides effective EMI/RFI shielding and good thermal dissipation.

The Hot Chamber Die Casting Process

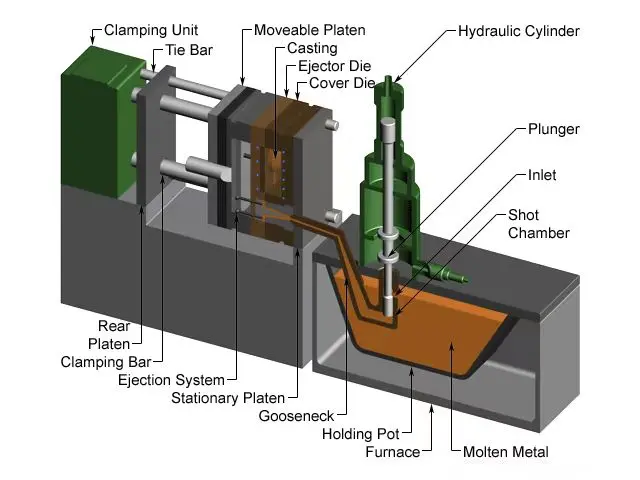

Magnesium is primarily formed using the efficient hot chamber die casting process. The injection system is submerged in molten metal, enabling rapid, automated cycles ideal for high-volume production.

The streamlined process involves five key stages:

Clamping & Lubrication: The mold is closed and sprayed with a release agent.

Injection: Molten magnesium is forced at high pressure into the die cavity.

Cooling & Solidification: The part solidifies under pressure within the water-cooled die.

Ejection: The die opens, and the casting is ejected.

Trimming & Finishing: Excess material is removed, and secondary finishing is applied.

Key Advantages: Beyond Light Weight

In the pursuit of efficiency and innovation in modern manufacturing, the value of a technology often extends far beyond its most apparent feature. While weight reduction is significant, the true transformative potential lies in how this advantage synergizes with other core strengths to reshape product design, manufacturing processes, and business competitiveness. The following key benefits demonstrate that it is not merely about being lighter—it is about enabling greater flexibility, cost efficiency, and precision in manufacturing.

Advantage | Impact on Design & Business |

Weight Reduction | Directly improves fuel efficiency in vehicles, battery life in electronics, and portability. |

Design Freedom | Allows for part consolidation and intricate geometries, reducing assembly steps. |

High Productivity | Fast hot-chamber cycles combined with easy machinability lower per-part cost. |

Dimensional Stability | Produces parts with minimal shrinkage and tight tolerances, ready for assembly. |

Important Considerations & Challenges

A balanced evaluation is crucial. Magnesium die-cast presents specific challenges that must be planned for:

Corrosion Sensitivity: While alloys improve resistance, parts exposed to harsh environments (e.g., marine, automotive underbody) require protective coatings like plating, anodizing, or painting.

Higher Raw Material Cost: Magnesium alloy cost is typically higher than aluminum. The justification comes from the value of weight savings and performance in the final application.

Specialized Handling Required: Molten magnesium must be processed under a protective gas atmosphere (e.g., SF6/CO₂ mix) to prevent oxidation, necessitating expert foundry partners.

Limited High-Temperature Options: For applications consistently above ~150°C, alloy selection becomes critical, with fewer high-creep-resistance options than aluminum.

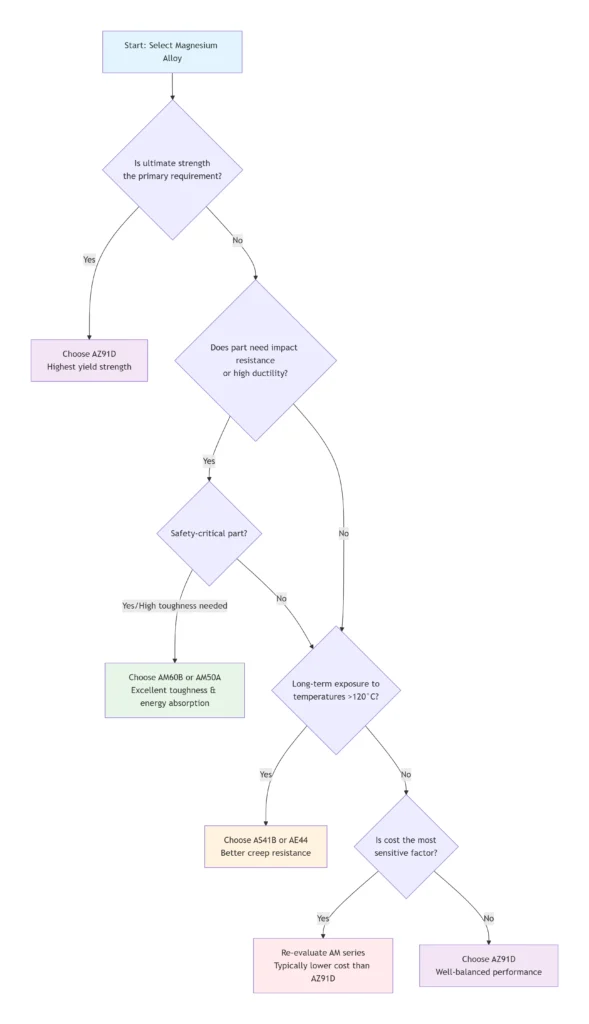

Choosing the Right Magnesium Alloy

Selecting the optimal alloy is key to balancing properties, cost, and performance:

|

Magnesium Number |

Features |

Applied for |

|

AZ91D |

The most common alloy |

Consumer electronics housings, power tool bodies. |

|

AM60B & AM50A |

Provide higher ductility and impact toughness |

Automotive seating and steering components where safety is critical |

|

AS41B & AE44 |

Offer improved creep resistance at elevated temperatures |

Engine and transmission components |

An Engineer’s Decision Flowchart

Primary Applications Across Industries

Automotive

Consumer Electronics

Aerospace

FAQ

Q1: Is magnesium die casting more expensive than aluminum die casting?

A: The raw material cost is higher, but the total cost can be competitive due to faster production cycles, less machining, and the high value of weight savings in performance-critical applications.

Q2: How does corrosion resistance compare to aluminum, and how is it managed?

A: Standard alloys have good resistance in many environments, but for harsh conditions, high-purity alloys and protective coatings (like anodizing or plating) are essential, unlike some aluminum alloys.

Q3: Can magnesium die casting be used for high-temperature applications like engine parts?

A: Yes, within limits. Specialized alloys like AE44 are used for components such as transmission cases (up to ~200°C), but aluminum is still preferred for the highest-temperature parts like cylinder blocks.

Q4: Why is a "hot chamber" process specifically used for magnesium?

A: Magnesium’s lower melting point and favorable chemistry make the hot chamber process ideal, enabling faster cycle times and higher productivity compared to the cold chamber process used for aluminum.

Conclusion

Magnesium die casting is a powerful technology for achieving radical lightweighting and functional integration. By understanding its full spectrum of advantages, considerations, and material options, engineering and product design teams can make informed decisions to drive innovation.