Why Your 2026 Partner Choice Matters More Than Ever

The high-pressure aluminum die casting sector stands at a crossroads — and your choice of an aluminum die casting partner in 2026 will define your success. As 2026 approaches, the industry is transforming at an unprecedented pace, driven by technological disruption and evolving global standards. Your choice of a precision die casting supplier will fundamentally determine your product integrity, supply chain agility, and market edge in the years ahead.

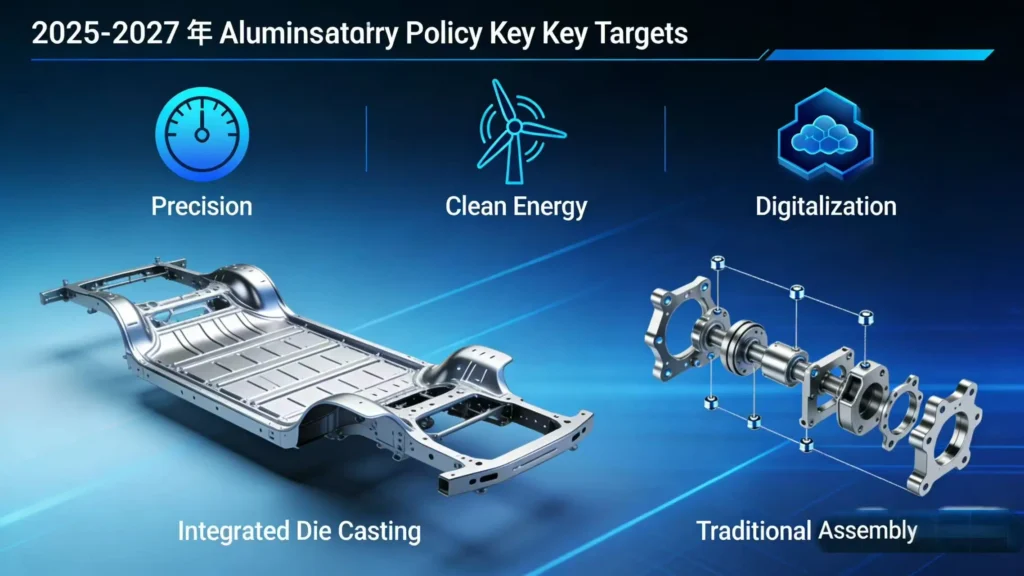

The urgency is underscored by recent policy shifts. In 2025, a consortium of ten Chinese government bodies released the Aluminum Industry High-Quality Development Implementation Plan (2025-2027). This blueprint mandates significant advancements in precision casting technology, a clean energy utilization rate exceeding 30%, and the rapid adoption of digitalization across the sector. This regulatory drive is reshaping the competitive landscape, prioritizing sustainable metal casting and smart manufacturing.

Concurrently, technological innovations like mega or giga casting—popularized by automotive leaders—are redefining production paradigms. This technique consolidates numerous components into a single, complex aluminum alloy casting, offering immense gains in strength, weight reduction, and assembly efficiency.

This guide delivers an actionable, step-by-step framework to navigate this new era. By following our structured evaluation, you can secure a partnership that aligns with both immediate project goals and your long-term strategic vision.

2026 Die Casting Partnerships: Costly Mistakes vs. Winning Results

3 Failure Cases of Choosing the Wrong Partner

- Tech Gap: An electronics parts maker used a non-single-piece partner—5-piece assemblies caused 8% cracking, costing $300k in recalls.

- Quality Issues: A home appliance firm relied on manual inspection—15% size errors led to $75k in retailer fines.

- Compliance Risks: A hardware factory’s partner failed 2026 carbon standards—production halted, costing $150k in overseas order penalties.

3 Success Cases of Choosing the Right Partner

- Cost Reduction: An auto wheel maker used 2026 single-piece tech—unit cost dropped from $11.5 to $8, saving $2M/year.

- Efficiency Boost: A telecom device firm used AI control—lead times fell from 15 to 10 days, increasing orders by 40%.

- Compliance Win: A medical device maker’s partner met EU 2026 eco-rules—securing a $450k export order.

Traditional VS. 2026 Future Aluminum Die Casting

Multi-Piece vs. Single-Piece Assembly

| Aspect | Multi-Piece Assembly Aluminum Die Casting (Batch Production) | Single-Piece Assembly Aluminum Die Casting (One-Piece Flow) |

|---|---|---|

| Production Style | Producing groups (batches) of identical items | Producing one item at a time, moving it through each process step before starting the next |

| Pros |

|

|

| Cons |

|

|

| Best Suited For |

|

AI Process Control vs Manual Quality InspectionAI Process Control: Pros: Cons: Manual Quality Inspection: Pros: Cons: FAQ for the Cost and Lead Time

|