Precision Die Casting Solutions for Mechanical Industry Components

At IEC Mould, we specialize in delivering high-performance, OEM-ready die-cast components for the mechanical industry. From industrial pumps, valves, and gear housings to automotive brackets and enclosures, our components are engineered to meet strict mechanical performance requirements while ensuring dimensional accuracy, surface quality, and production efficiency.

Why choose IEC Mould?

- Full-service OEM die casting solutions: DFM → Tooling → Casting → CNC → Finishing → Assembly

- Expertise in aluminum, zinc, magnesium, and copper alloys

- Proven track record with tens of thousands of components produced

- ISO 9001 & IATF 16949 certified, with robust QA and traceability systems

Why High-Performance Die Casting is Critical for Mechanical Components

Mechanical components face extreme operational demands:

- High tensile strength and impact resistance to endure vibration, load, and thermal stress

- Tight dimensional tolerances for precision assembly and smooth operation

- Surface quality and corrosion resistance for long-term reliability

- Complex geometries that traditional casting or machining methods cannot easily achieve

IEC Mould solution: We integrate engineering expertise, Moldflow simulation, DFM, CNC machining, and surface finishing to deliver defect-free, OEM-ready mechanical components.

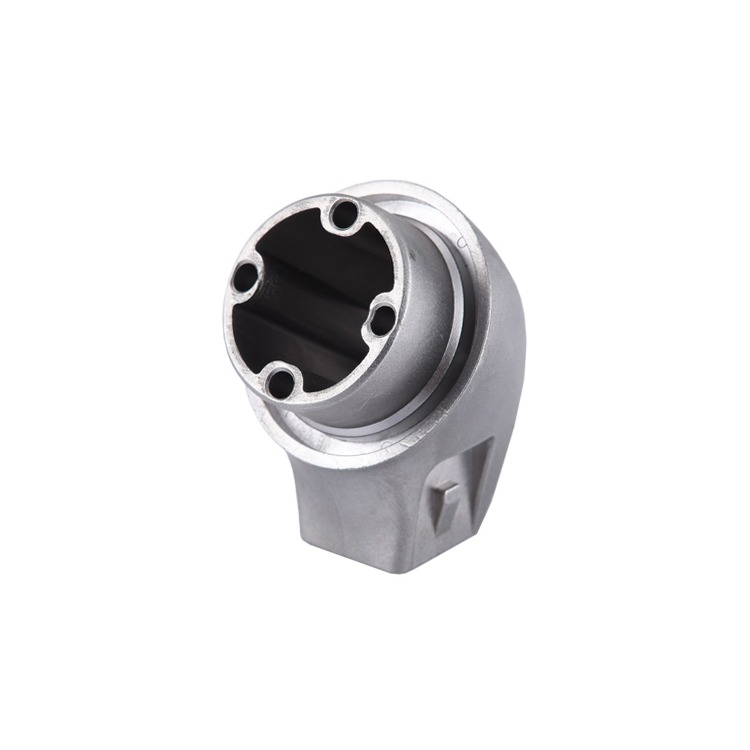

Example: Our industrial pump housing, cast in Aluminum A380, maintains ±0.1 mm tolerances while achieving high tensile strength, making it ready for assembly without modifications.

Case Studies – Real IEC Mould Mechanical Parts

We manufacture a wide range of die cast and machined components for industrial machinery OEMs, including:

- Pump and hydraulic housings

- Valve bodies and manifold blocks

- Gearbox and motor housings

- Pneumatic actuator bodies

- Structural brackets and mounting bases

- Enclosures and protective covers

- Motion control components (sliders, guides, carriers)

These components typically require:

- High strength-to-weight ratio

- Dimensional accuracy for mating & sealing surfaces

- Corrosion resistance in outdoor/industrial environments

- CNC machining for critical interfaces

- Leak testing for fluid & air systems (optional)

- Surface finishing such as anodizing, powder coating or plating

Our Mechanical Die Casting Capabilities

Materials We Use

We select materials based on strength, weight, corrosion resistance, and thermal performance. Here’s a snapshot:

| Material | Properties | Typical Applications | IEC Mould Example |

|---|---|---|---|

| Aluminum (A380, ADC12) | High strength-to-weight, corrosion-resistant | Pump housings, gear cases, automotive brackets | Pump Housing, 200×150×120 mm, tensile strength 220 MPa |

| Zinc (Zamak 3/5) | High dimensional accuracy, smooth surface finish | Precision valves, small mechanical assemblies | Valve Body, 90×60×50 mm, plating finish |

| Magnesium (AZ91, AM60) | Lightweight, machinable | Automotive brackets, aerospace components | Gear Housing, 150×120×80 mm, weight 1.8 kg |

| Copper alloys | Thermal/electrical conductivity | Heat sinks, connectors | Custom electrical housing, high conductivity, CNC machined |

Our expertise: IEC Mould helps OEM clients choose optimal materials for each mechanical application, balancing performance, cost, and manufacturability.

DFM for Mechanical Parts

Design for Manufacturing (DFM) is critical to avoid defects, reduce cost, and streamline production. Key considerations include:

- Wall thickness optimization: Prevents porosity and ensures uniform solidification.

- Rib and boss design: Enhances structural strength without excessive material use.

- Draft angles: Ensures easy ejection from molds.

- Fillet radii and corner design: Reduces stress concentrations and improves flow.

Our DFM service combines CAD simulation, mold flow analysis, and engineering consultation to ensure parts are manufacturable at scale without compromising performance.

High-Precision Tooling & Moldflow Optimization

Advanced tooling and Moldflow analysis guarantee defect-free die casting. We provide:

- High-precision mold design with hardened steel inserts for long-lasting durability.

- Flow simulations: Predict filling patterns, air traps, and potential shrinkage areas.

- Thermal analysis: Ensures consistent solidification, reducing warpage.

- Iterative testing: Refines gate locations, vents, and cooling channels for optimal production efficiency.

By combining tooling expertise with Moldflow simulation, we minimize cycle times, reduce scrap rates, and ensure consistent part quality.

Example: Our pump housing Moldflow simulation ensures complete filling, minimal porosity, and ±0.1 mm dimensional accuracy, delivering repeatable high-quality parts.

Advanced CNC Machining & Post-Processing

Many die-cast mechanical components require secondary machining to meet tight tolerances. Key CNC requirements include:

- Surface flatness and finish: Ensures proper assembly.

- Threading and tapping: Precision holes for fasteners.

- Critical hole dimensions: Maintaining concentricity and alignment.

- Complex profiles and contours: Achievable with 3–5 axis CNC machining.

We provide fully integrated machining services in-house, eliminating the need for third-party subcontractors and reducing lead times.

Mechanical Part Performance & Tolerances

Mechanical components must withstand high stress, impact, and thermal expansion. IEC Mould guarantees tight tolerances:

| Feature | Standard Tolerance | Notes |

|---|---|---|

| Up to 50 mm | ±0.1 mm | Wall thickness dependent |

| 50–150 mm | ±0.2 mm | Critical for assembly |

| Over 150 mm | ±0.3 mm | Requires careful tooling |

| Holes < 10 mm | H7/H8 | For press-in parts |

| Complex features | ±0.05 mm | CNC finishing recommended |

We can customize tolerances based on part requirements, ensuring functional reliability and interchangeability.

Surface Treatments for Mechanical Components

We offer a wide range of surface treatments to enhance durability and aesthetics:

- Powder coating / Liquid painting: Corrosion resistance, color consistency.

- Anodizing (Aluminum): Protective oxide layer, improved wear resistance.

- Plating (Zinc/Nickel/Chrome): High corrosion and decorative finish.

- Sand blasting / Brushing: Texture control for functional or aesthetic purposes.

- Custom coatings: PTFE, anti-galling, or chemical-resistant treatments.

Surface treatments are fully integrated with QA processes to ensure uniform coverage and long-term performance.

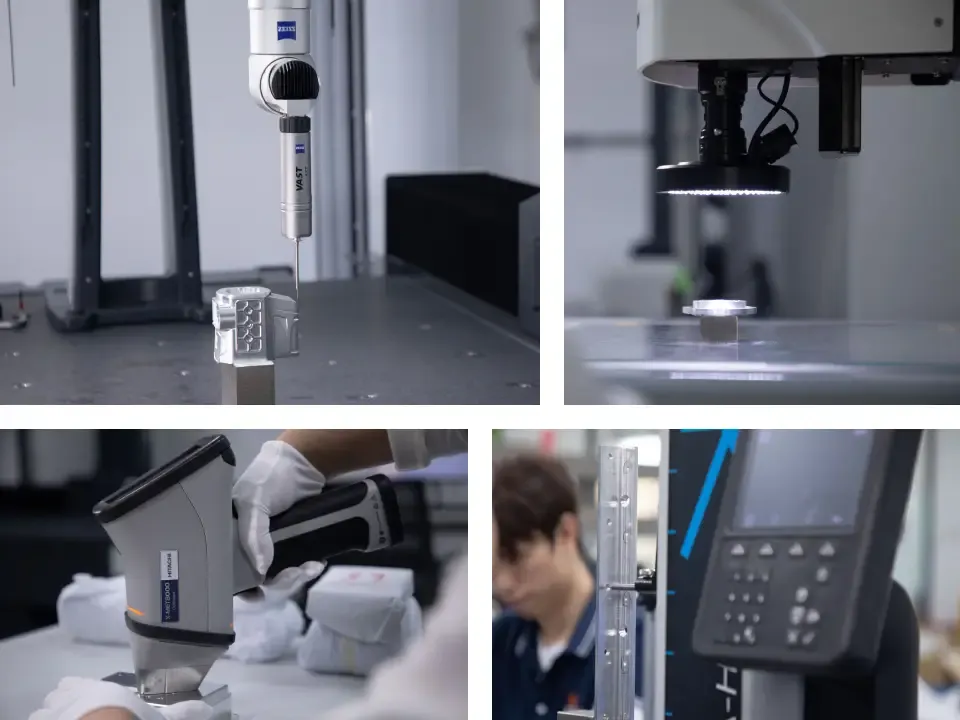

Quality Assurance & Testing

Our QA process guarantees mechanical and dimensional integrity:

- X-ray / CT scanning: Detects internal porosity and defects.

- Tensile and hardness testing: Confirms alloy properties meet specifications.

- Surface roughness measurement: Ensures coating adhesion and assembly precision.

- Functional testing: Simulates operational loads and environmental conditions.

All processes comply with ISO 9001 / IATF 16949 standards, providing full traceability and inspection reports for each batch.

Get Your Custom Mechanical Component Quote Today

Transform your mechanical designs into high-performance, OEM-ready die-cast components.