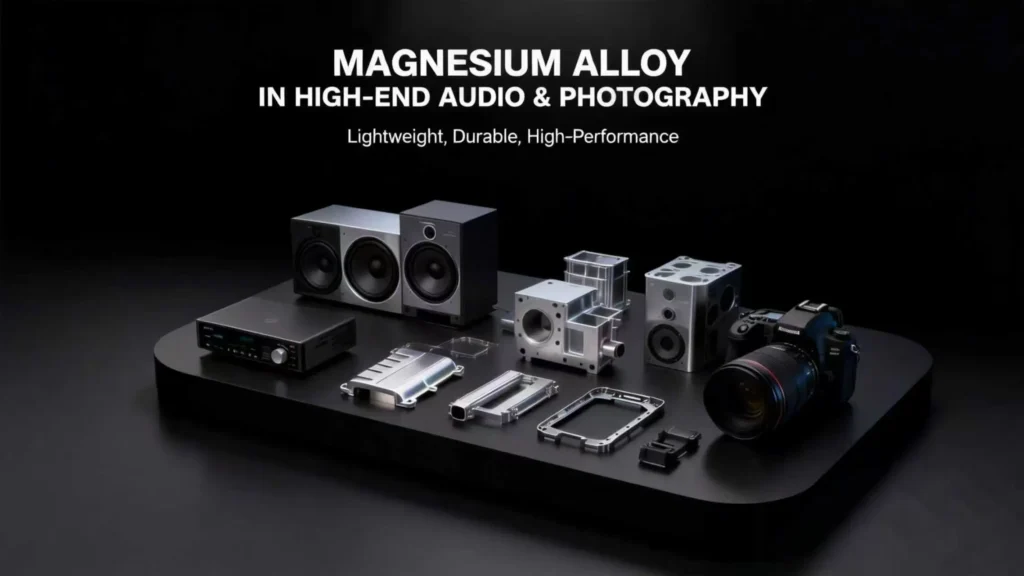

In the relentless pursuit of perfection within high-end audio and professional photography, every component is scrutinized. While discussions often center on exotic speaker drivers, pristine DACs, or advanced image sensors, a silent champion underpins the performance of the world’s most revered gear: magnesium die casting. This material is not merely a housing; it’s a foundational technology that directly enhances user experience and engineering outcomes.

Far from being a simple metal, magnesium alloys are the strategic choice for engineers demanding an unmatched combination of properties. This article explores the six pivotal reasons why magnesium alloys, delivered via sophisticated die-casting processes, have become the backbone of professional cameras, high-fidelity speakers, and critical audio components.

The Core Advantages of Magnesium Alloy

Magnesium’s dominance in premium applications stems from a unique synergy of physical properties, as highlighted in industry analyses on its rising use. Here’s why it outperforms alternatives like aluminum or plastics:

Superior Strength-to-Weight Ratio

Magnesium is approximately 33% lighter than aluminum and 75% lighter than steel while offering comparable specific strength. This allows for robust, durable constructions without burdening the user—a critical factor for handheld cameras or heavy amplifiers.

Exceptional Damping Capacity

Magnesium alloys absorb vibrational energy significantly better than aluminum. This intrinsic damping reduces resonant vibrations that can color audio output or blur images through microscopic camera shake.

Effective Electromagnetic Interference (EMI) Shielding:

In our digitally saturated environments, magnesium acts as a Faraday cage, protecting sensitive internal circuits from external EMI and preventing internal signals from leaking—a non-negotiable for clean audio signals and digital image integrity.

Excellent Thermal Conductivity

It efficiently dissipates heat from power amplifiers, processors, or sensors, maintaining optimal operating temperatures and ensuring long-term stability and reliability. This thermal management is greatly enhanced by the excellent processability of magnesium die casting, which allows for the integration of heat-dissipating fins within complex chassis designs.

High Precision & Design Freedom

The magnesium die casting process enables the production of complex, thin-walled, and net-shape components with high dimensional stability and excellent surface finish, perfect for intricate designs.

Revolutionizing the Soundstage: Magnesium in High-End Audio

The quest for pure, uncolored sound drives audio engineers to components made via magnesium die casting. This process is critical for components.

Speaker and Headphone Frames

Resonant enclosures distort sound. Magnesium’s high damping factor minimizes enclosure vibration, allowing the driver’s output to be heard without additive “color.” This results in clearer transients and a more accurate soundstage. Companies like Foxconn have demonstrated through case studies how precision etching of magnesium parts, often post-die-casting, achieves unparalleled tolerances and functional designs for audio components

Chassis for Amplifiers & Digital Components

A magnesium alloy chassis serves a dual purpose. First, its EMI shielding creates a quiet environment for low-voltage analog and digital circuits. Second, its rigidity forms a stable platform for internal boards and connectors, minimizing microphonic effects.

Turntable Platters and Tonearms

In analog playback, eliminating vibration is paramount. Magnesium platters offer superb rotational stability with low mass, while tonearms benefit from the material’s stiffness and damping to accurately trace record grooves.

Capturing the Decisive Moment: Magnesium in Professional Photography

For photographers, reliability is as crucial as image quality. Camera bodies crafted through magnesium die casting are the industry standard for professionals, and for good reason.

Rugged, Lightweight Camera Bodies

A full-frame DSLR or mirrorless camera with a magnesium alloy frame offers a perfect balance. It withstands the rigors of daily professional use and harsh environments while maintaining a manageable weight for extended shoots. This durability, often including weather-sealing built into the cast frame, is a key marketing point for flagship cameras.

Lens Barrels and Internal Mechanisms

High-performance lenses, especially fast primes and long telephotos, utilize magnesium for barrel construction. The material maintains precise optical alignment under temperature variations and physical stress. Its lightness also contributes to faster autofocus performance by reducing the moving mass of focus groups.

Supporting Gear: Gimbals & Tripods

The stability benefits extend to accessories. High-end tripod heads and drone gimbals utilize magnesium to minimize overall weight without compromising the rigidity required for rock-solid camera support or smooth, vibration-damped footage.

The Manufacturing Edge: High-Pressure Magnesium Die Casting

The realization of these benefits hinges on advanced manufacturing. High-pressure magnesium die casting is the predominant method. It involves injecting molten magnesium alloy into a precision steel mold under high pressure. This allows for:

Complex Geometries

Creating single-piece structures with integrated ribs, bosses, and heat sinks that would be impossible or costly to machine.

Excellent Surface Finish & Detail

Achieving fine details directly from the mold, reducing the need for secondary machining.

Cost-Effectiveness at Volume

Once the mold is created, producing large quantities of consistent, high-tolerance parts is highly efficient.

Selecting the right material for high-end enclosures is critical for electronic devices, automotive components, and industrial equipment. Different materials offer distinct advantages in weight, damping, rigidity, EMI shielding, and cost.

The comparison table below details the key characteristics of three common high-end enclosure materials to help make informed decisions based on specific application requirements.

| Property |

Magnesium Alloy

Lightweight metal with good damping

|

Aluminum Alloy

Durable with excellent thermal properties

|

Advanced Polymers

Carbon-fiber reinforced composites

|

|---|---|---|---|

|

Weight

Lighter materials improve portability and energy efficiency

|

Very Light

Density ~1.8 g/cm³

|

Medium

Density ~2.7 g/cm³

|

Lightest

Density 1.2-1.6 g/cm³

|

|

Damping

Ability to absorb vibrations and reduce noise

|

Excellent

Superior vibration absorption

|

Poor

Prone to vibration transmission

|

Good

Depends on composite formulation

|

|

Rigidity/Stiffness

Resistance to deformation under load

|

Medium

High strength-to-weight, limited stiffness

|

Excellent

High stiffness, structurally stable

|

Tunable

Carbon fiber can provide high stiffness

|

|

EMI Shielding

Protection against electromagnetic interference

|

Good

Conductive metal, natural shielding

|

Excellent

Best electromagnetic shielding

|

Requires enhancement

Needs conductive fillers or coatings

|

|

Cost

Material and manufacturing expenses

|

High

High material & processing costs

|

Medium

Mature processing, good value

|

Low to High

Wide range based on specific material

|

Magnesium alloys excel in weight reduction and damping performance, making them ideal for high-end applications requiring vibration reduction and lightweight properties, though they come with higher costs and medium EMI shielding.

Aluminum alloys offer the best rigidity and EMI shielding with moderate costs, making them the standard choice for many electronic products and automotive components.

Advanced polymers are the lightest option with tunable properties through composite formulation, but require additional treatment for EMI shielding and have a wide cost range.

Note: Actual performance depends on alloy composition, manufacturing processes, design structure, and surface treatments. This comparison is based on general characteristics. Specific selections should be evaluated based on application requirements.

FAQ

Are magnesium alloy camera bodies significantly more expensive?

Initially, yes. The material and precision die-casting process have higher upfront costs than polycarbonate. However, the benefits in durability, performance, and perceived value make it a necessary investment for professional and high-end equipment, justifying the price premium.

How can I tell if my device has a real magnesium alloy frame?

Manufacturers typically explicitly advertise “magnesium die casting chassis” or “magnesium die casting frame” as a key feature. Technically, magnesium is non-magnetic, so a strong magnet will not stick to a pure magnesium part (though some internal steel screws may cause slight attraction). The material also feels distinctly lighter and more “dense” than plastic counterparts.

Is magnesium strong enough? Isn't it brittle?

Modern magnesium die casting alloys(like AZ91D or AM60B) offer excellent strength and toughness. While not as ductile as some aluminums, their superior strength-to-weight and damping properties make them ideal for structural housings. Their performance in demanding real-world use across industries is the best testament to their durability.

Future Trends and Conclusion

The application of magnesium alloys is expanding into portable high-fidelity audio, professional video equipment, and broadcast gear. As the demand for devices that are both lightweight and phenomenally capable grows, magnesium’s role will only solidify.

In conclusion, specifying components made via magnesium die casting is a commitment to performance integrity. For the audiophile, it’s the guardian of acoustic purity. For the photographer, it’s the assurance of reliability when capturing a once-in-a-lifetime shot. It represents a harmony of material science and precision die-casting engineering that truly defines what makes gear “professional grade.”