Have you ever held a lightweight yet sturdy aluminum die casting part from a car, a laptop, or a power tool and wondered, “How was this made so precisely and efficiently?” The answer, more often than not, is the aluminum die casting process. This high-pressure manufacturing technique is the backbone of mass-producing complex, dimensionally accurate, and durable metal parts. But what exactly is die cast aluminum? In simple terms, it’s the process and the resulting product created by forcing molten aluminum into a mold under high pressure.

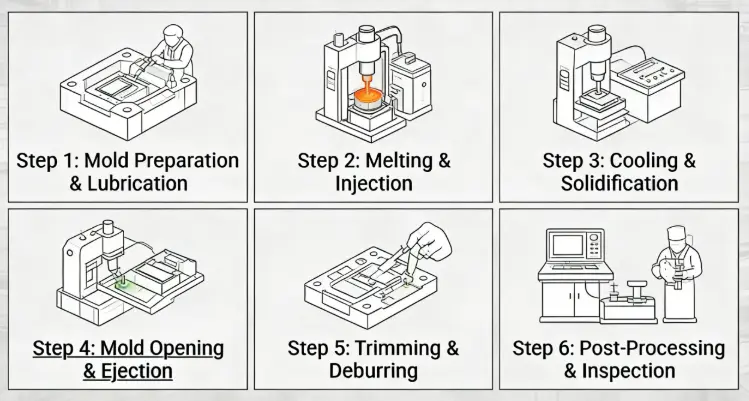

But what exactly happens inside a die casting machine? The aluminum casting process may seem shrouded in industrial mystery, yet it follows a meticulously engineered sequence. Understanding the aluminum die casting process is key for designers, engineers, and procurement specialists to leverage its full potential. In this definitive guide, we will demystify the entire aluminum die casting process by breaking it down into six critical, sequential steps. By the end, you’ll have a clear blueprint of how to cast aluminum into a finished, high-integrity component, from aluminum die casting mold to final part.

Step 1: Mold Preparation & Lubrication

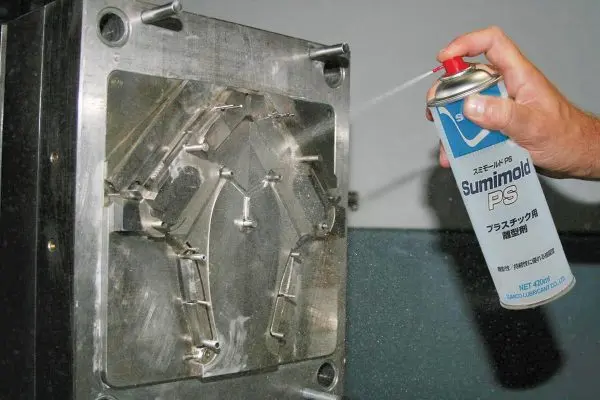

Before molten aluminum enters, the stage is set inside the die casting mold. This preparatory phase is the foundational first step in the aluminum die casting process. Proper lubrication ensures the success of subsequent stages in the aluminum die casting process.

Clamping: The two mold halves are securely clamped together under immense force (often hundreds to thousands of tons) by the die casting machine. This ensures the mold remains completely sealed against the high pressures to come.

- Lubrication & Cooling: A specialized water-based lubricant or release agent is then sprayed onto the mold’s cavity surfaces. This is a critical die casting process step with three vital functions: aiding release, cooling, and protecting the aluminum die casting mold.

It creates a barrier to prevent the molten aluminum from welding to the steel mold, allowing for clean part ejection.

It helps control the mold temperature by providing a cooling effect, which is crucial for managing the solidification rate.

It protects the expensive mold from thermal shock and wear, extending its lifespan.

Why it matters: Skipping or inadequately performing this step leads directly to major die casting defects like sticking, soldering, and premature mold failure, resulting in costly downtime.

Step 2: Melting & Injection

This is where the core action of the aluminum die casting process begins. The cold chamber die casting method, standard for aluminum, involves injecting molten metal at high speed and pressure. Mastering this injection phase is crucial to the overall aluminum die casting process.

- Melting: The aluminum cast alloy is melted in a central furnace at temperatures around 660°C (1220°F) and held in a ready state.

- Transfer & Injection: For most aluminum casting, the cold chamber die casting method is standard. A precise amount of molten aluminum is transferred via a ladle into the “shot sleeve” (a horizontal cylinder). A powerful hydraulic piston then rams forward at high speed, forcing the metal into the mold cavity under high pressure. This step defines what is die cast aluminum– it’s all about high-pressure injection.

Key Insight: The injection phase is split into two stages: a fast first stage to fill the cavity before the metal solidifies, followed by an intensification stage to apply maximum pressure to pack the metal densely and compensate for shrinkage.

Step 3: Cooling & Solidification

The controlled solidification within the mold is what gives die cast aluminum its strength and defines the precision of the entire aluminum die casting process.

The molten metal cools from the outside in, taking the exact shape of the cavity.

The intensification pressure applied during injection is maintained for a critical few seconds. This “hold time” ensures that additional molten metal is forced into the cavity to compensate for volumetric shrinkage as the aluminum solidifies, minimizing internal porosity and ensuring a dense, strong part structure.

Process Control: The cooling time must be carefully calculated. Too short, and the part may be soft or warp upon ejection; too long, and it reduces production cycle time unnecessarily. This step is fundamental to achieving the high integrity associated with high pressure die casting.

Step 4: Mold Opening & Ejection

After solidification, the mold opens to eject the part. The reliability of this step directly impacts the cycle time and efficiency of the aluminum die casting process.

Mold Opening: The die casting machine opens the mold by retracting the movable platen, separating the two mold halves.

Part Ejection: Built-in ejector pins, driven by a mechanism in the ejector half of the mold, then advance uniformly to push the now-solid aluminum casting out of the cavity. In automated setups, a robotic arm often immediately reaches in to extract the part, placing it on a conveyor or cooling rack.

Hot chamber die casting is used for lower-melting-point metals like zinc, where the injection mechanism is immersed in the molten metal. Cold chamber die casting, used for aluminum, involves transferring molten metal into a separate injection cylinder to prevent prolonged contact and erosion of the components.

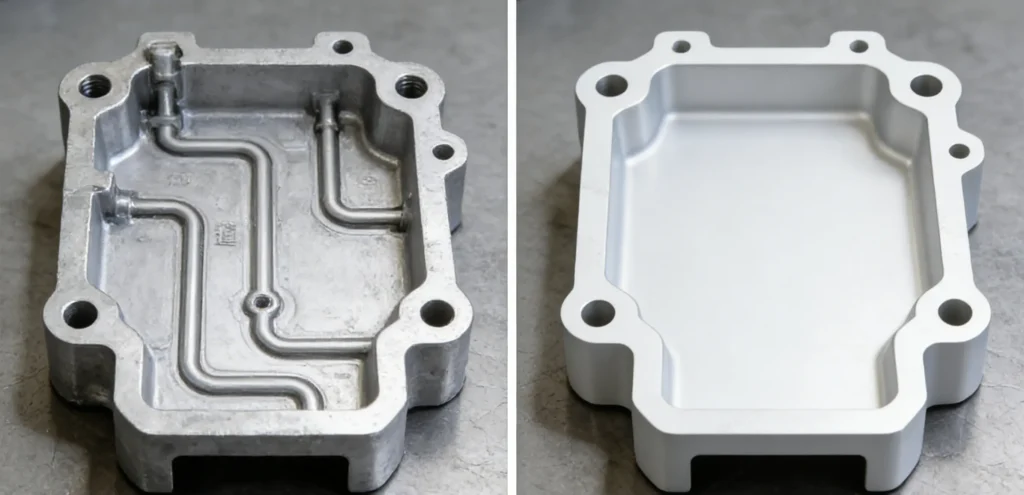

This step marks the birth of the “raw” casting, complete with its attached network of excess material.

Step 5: Trimming & Deburring

The part ejected from the mold is not yet finished. It remains connected to the leftover material from the flow channels, known as the “biscuit,” “sprue,” “runners,” and “gates,” along with thin flash from parting lines.

Trimming: The casting is placed into a trimming press or trim die, a separate tool that cleanly shears off all this excess material in one powerful stroke. The removed scrap is 100% recyclable, being remelted for future shots, making the aluminum die casting process highly sustainable.

Deburring: The trimmed part may then undergo deburring to remove any sharp edges or minor imperfections left at the trimming points, often via vibrating tumblers, abrasive blasting, or manual filing.

Step 6: Post-Processing & Inspection

The final step ensures parts meet specifications. Rigorous inspection is the quality gatekeeper of the aluminum die casting process, ensuring that only aluminum die casting parts are shipped.

Post-Processing: Depending on the application, aluminum die casting parts may undergo.

- Machining: Precision drilling, tapping, or milling to achieve tolerances or features not possible in the casting itself.

- Surface Finishing: Techniques like sandblasting, polishing, powder coating, anodizing, or plating to enhance appearance, corrosion resistance, or wear properties.

Quality Inspection: This ensures the aluminum die cast material meets specifications.

- Dimensional checks with gauges or CMM (Coordinate Measuring Machines).

- Visual inspection for surface defects.

- Advanced methods like X-ray inspection to detect internal porosity or defects.

- Mechanical property testing to ensure strength specifications are met.

Only after passing inspection is the aluminum die casting considered complete and ready for shipment.

Why Choose Aluminum Die Casting Process?

This six-step aluminum die casting process delivers unmatched advantages:

High Efficiency & Volume: Capable of producing tens of thousands of parts with minimal cycle times.

Exceptional Precision & Detail: Creates complex shapes with tight tolerances and excellent surface finishes.

Thin Walls & Lightweight: Allows for strong, lightweight designs crucial in automotive and aerospace.

Superior Strength: Parts have high strength-to-weight ratios and good dimensional stability.

FAQ for Aluminum Die Casting Process

What is the difference between hot chamber and cold chamber die casting?

Hot chamber die casting is used for lower-melting-point metals like zinc, where the injection mechanism is immersed in the molten metal. Cold chamber die casting, used for aluminum, involves transferring molten metal into a separate injection cylinder to prevent prolonged contact and erosion of the components.

What are common aluminum alloys for die casting?

The most widely used alloys are A380 (excellent fluidity and strength) and ADC12 (similar, with high silicon content for castability). Others include A360 (high corrosion resistance) and A413 (excellent pressure tightness).

How do you control porosity in aluminum die casting?

Porosity is controlled through several key factors: proper venting of the mold, optimized injection speed and pressure to avoid turbulence, applying adequate intensification pressure during solidification, and precise control of mold temperature and alloy quality.

What is a typical tolerance for aluminum die casting?

Standard linear tolerances are typically around ±0.002 inches per inch (±0.05mm per 25mm) for the first inch, with an additional allowance for larger dimensions. Tighter tolerances can be achieved for critical features with aluminum die casting process optimization.

What are the main advantages over other processes like sand casting?

Compared to sand casting, die casting offers much higher production speeds, superior surface finish, tighter dimensional accuracy, and the ability to produce thinner walls. Sand casting is better suited for very large, low-volume parts where tooling cost for a die would be prohibitive.

Conclusion

The aluminum die casting process is a symphony of precision engineering, high pressure, and controlled thermodynamics. From the critical preparation of the die casting mold to the final quality inspection, each of the six steps plays an indispensable role in manufacturing the strong, lightweight, and complex components that power modern industry. By mastering this aluminum die casting process, manufacturers can achieve unparalleled efficiency and part quality, solidifying die casting’s role as a cornerstone of advanced manufacturing.