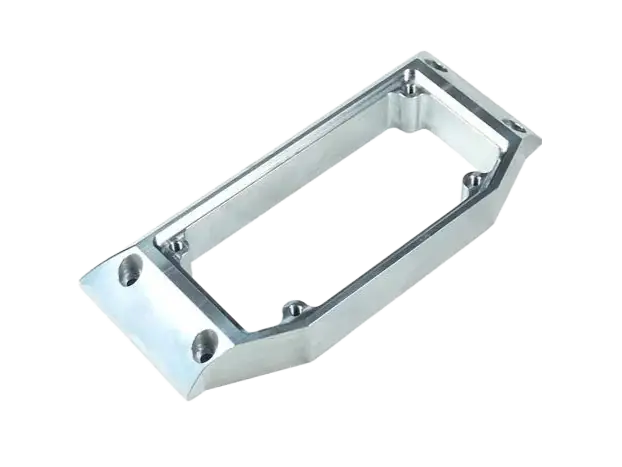

Die Casting Plating Services

IEC Mould provides die casting plating services for aluminum and zinc components, offering durable metallic coatings with controlled adhesion and consistent surface quality. By applying electroplating processes optimized for die cast substrates, we ensure reliable performance for functional and appearance-critical parts.

Our plating solutions focus on corrosion resistance, coating stability, and production consistency.

- Stable adhesion on die cast parts

- Uniform coating on complex features

- Improved corrosion and wear resistance

- Suitable for aluminum and zinc die casting

What Is Die Casting Plating?

Die casting plating is an electrochemical surface finishing process in which a metallic layer is deposited onto die cast parts to improve corrosion resistance, surface durability, and functional performance.

Unlike coating processes that form a thick external film, electroplating creates a thin, uniform metallic layer that closely follows the geometry of the part. When properly engineered, it is suitable for aluminum and zinc die cast components requiring controlled thickness, strong adhesion, and reliable surface performance. However, successful plating on die cast parts depends heavily on substrate quality, surface preparation, and porosity control—factors that are often overlooked when plating is treated as a standalone process.

Why Plating Is widely Used for Die Cast Parts

Die casting plating is selected when components require precise metallic surface performance that coatings alone cannot provide. It is widely applied in functional, decorative, and tolerance-sensitive applications where controlled thickness, conductivity, or enhanced surface hardness is critical.

Key Advantages

- Thin, controlled metallic layers with predictable thickness

- Improved corrosion and wear resistance

- Strong adhesion on properly prepared aluminum and zinc die cast substrates

- Excellent conformity to complex features and sharp details

- Suitable for both functional and decorative surface requirements

Engineering Reality

Die casting plating is not a simple post-process. Surface porosity, alloy composition, trapped gases, and pretreatment quality directly affect adhesion and long-term stability. Without proper substrate control, electroplated layers may blister, peel, or corrode prematurely.

Our Integrated Approach

By aligning die casting process control with electroplating requirements, we manage substrate quality, surface preparation, and plating parameters as a single system. This integrated approach reduces plating risk, improves consistency, and delivers reliable surface performance in production.

Plating Die Casting Manufacturing Advantage

Most plating failures don’t originate in the plating bath—they begin at the casting stage. When die casting and electroplating are managed by separate suppliers, porosity variation, alloy inconsistency, surface contamination, and uncontrolled handling often remain hidden until adhesion or blistering issues occur. By integrating die casting and plating within one controlled manufacturing system, this disconnect is eliminated.

- Die casting parameters are optimized to reduce porosity and gas entrapment before plating

- Parts enter surface preparation immediately, avoiding oxidation and handling damage

- Casting and plating teams align on alloy condition and pretreatment requirements

- Each batch follows a controlled path from casting to electroplated finish

The result is not simply a plated surface, but a stable metallic layer with reliable adhesion and performance—engineered to withstand real service conditions rather than masking substrate-related risks.

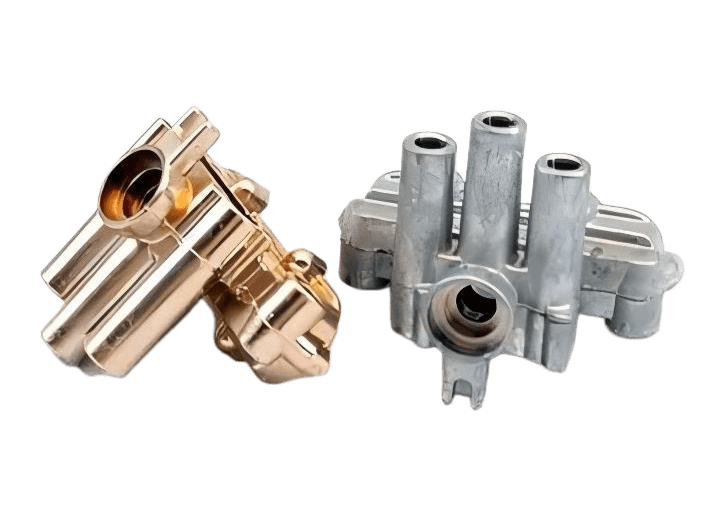

Plating for Suitable Die Casting Materials

The success of die casting plating depends not only on the electroplating process itself, but also on alloy composition, casting quality, and surface condition. Aluminum and zinc die castings are the most commonly plated materials when plating requirements are defined early and substrate control is properly managed.

Aluminum Die Casting

Common alloys: ADC12, A380, AlSi series

Aluminum die castings can be electroplated for functional and decorative purposes when advanced pretreatment and activation processes are applied. Properly prepared aluminum substrates allow plated layers to deliver corrosion resistance, wear protection, and controlled surface performance.

Why aluminum can be plated successfully:

- Enables thin, functional metallic layers with controlled thickness

- Improves corrosion resistance in demanding environments

- Suitable for applications requiring dimensional control

- Supports multi-layer plating systems for performance enhancement

Our engineering control:

We manage alloy condition, porosity level, and surface activation to ensure stable adhesion and consistent plating performance from initial samples through mass production.

Zinc Die Casting

Common alloys: Zamak 3, Zamak 5

Zinc die cast parts are highly suitable for electroplating due to their excellent surface characteristics and predictable plating behavior. They are widely used for both functional and decorative plated applications.

Why zinc works well for die casting plating:

- Naturally compatible with electroplating processes

- Strong and reliable plating adhesion

- Uniform coating on fine details and complex geometries

- Consistent results across production batches

Engineering consideration:

Zinc plating performance depends on strict control of surface cleanliness and pretreatment timing. Our process ensures stable adhesion, uniform thickness, and long-term durability while maintaining part integrity.

How Our Die Casting Plating Process Works — Step by Step

Reliable die casting plating is never achieved by chance. It requires a tightly controlled, step-by-step process in which each stage directly affects adhesion, thickness control, and long-term surface performance.

1.Degreasing & Cleaning — Removing Hidden Risks

All oils, die release residues, and surface contaminants are thoroughly removed. This step is critical to prevent adhesion failure and ensure the plated layer bonds directly to the die cast substrate.

2. Surface Activation — Preparing the Substrate for Plating

Through alloy-specific chemical activation and pretreatment, the natural oxide layer is controlled and the surface is prepared to accept electroplating evenly and reliably.

3. Underlayer Preparation — Building a Stable Foundation

Where required, an intermediate metallic layer is applied to improve adhesion, level surface irregularities, and support the final plated finish.

4. Electroplating Application — Depositing the Functional Layer

The metallic coating is deposited under controlled current density and bath conditions, ensuring uniform thickness, precise coverage, and conformity to complex geometries.

5. Post-Treatment & Stabilization — Enhancing Durability

Plated parts undergo rinsing, neutralization, and optional sealing to improve corrosion resistance and stabilize long-term performance.

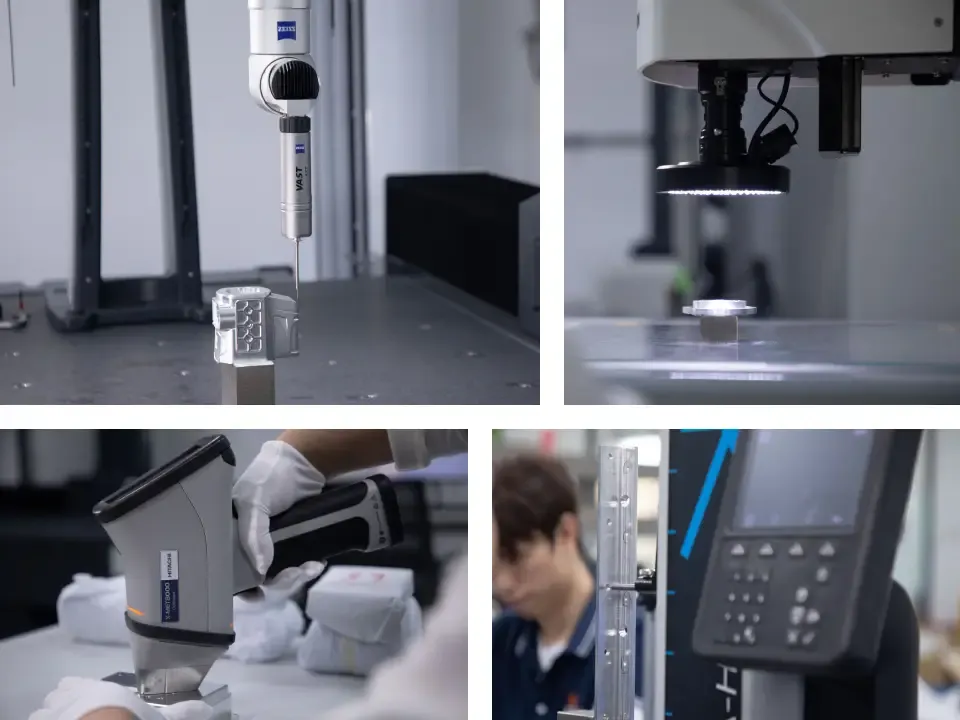

6. Final Inspection & Packaging — Verified Surface Performance

Each batch is inspected for adhesion, coating thickness, surface consistency, and appearance, ensuring the plated finish meets functional and quality requirements before delivery.

Surface Preparation — The Hidden Key to Consistent Die Casting Plating Results

In die casting plating, the metallic layer is only the final outcome. What truly determines adhesion strength, thickness stability, and long-term performance happens well before electroplating begins. For die cast parts, surface preparation is the decisive factor that controls how the plated layer bonds, grows, and performs over time.

Common Industry Challenges

Die cast components introduce substrate-related risks that directly affect plating quality and durability:

- Micro-porosity and trapped gases can lead to blistering or peeling after plating

- Residual release agents and surface contamination can prevent proper metal bonding

- Inconsistent surface activation may cause uneven thickness or localized adhesion failure

These issues are often invisible on raw castings and only emerge after plating or during service life—when correction is difficult and costly.

Our Control Measures

To achieve stable and repeatable plating results, our surface preparation focuses on how the die cast substrate interacts with the electrochemical process, not just whether the coating initially adheres.

- Alloy-specific cleaning and activation tailored for electroplating

- Porosity-aware pretreatment to minimize gas-related defects

- Controlled transition timing from casting to plating preparation

- Optimized surface condition for uniform current distribution

This approach ensures die casting plating delivers reliable adhesion, consistent thickness, and durable surface performance—not a plated layer that passes inspection once and fails in real-world use.

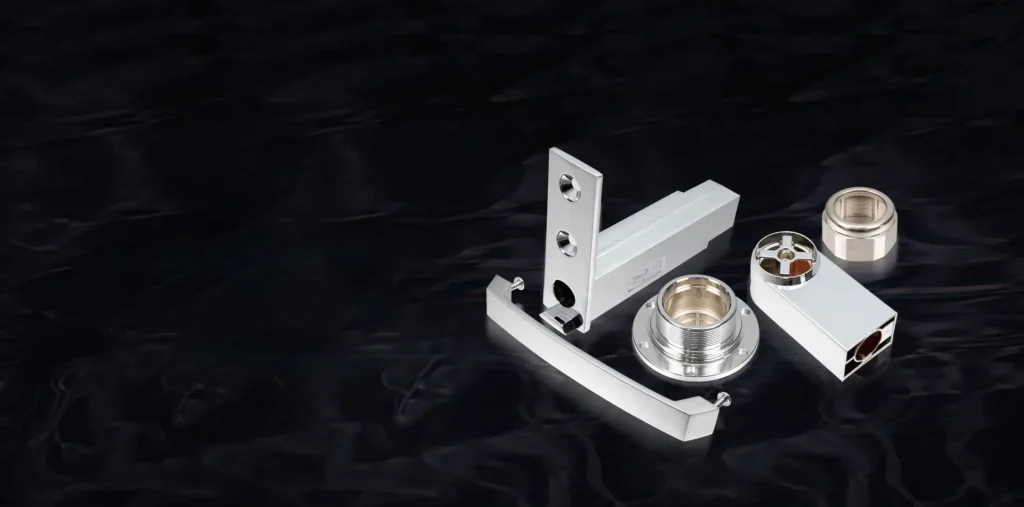

Die Casting Plating Types We Offer

Nickel Plating

– Commonly used for die cast parts requiring corrosion resistance, surface hardness, and stable functional performance; suitable for both decorative and functional applications.

Chrome Plating

– Applied where enhanced wear resistance, surface hardness, or premium metallic appearance is required; typically used on parts with higher surface performance demands.

Copper Plating (Underlayer)

– Used as an intermediate layer to improve adhesion, surface leveling, or electrical conductivity; generally not applied as a final functional finish on its own.

Multi-Layer Plating Systems

– Engineered for applications requiring optimized adhesion, durability, or corrosion resistance through layered metal structures; higher process control compared to single-layer plating systems.

Custom Plated Finishes for Die Cast Parts: Appearance, Performance & Control

We provide in-house die casting plating services to achieve controlled metallic finishes with reliable functional performance on aluminum and zinc die cast components. Our plating solutions focus on adhesion stability, thickness accuracy, and surface consistency—ensuring plated parts meet both technical and visual requirements.

- Plating Appearance Options:

Bright, semi-bright, or satin metallic finishes, suitable for functional parts with visible surfaces or decorative requirements. - Functional Surface Performance:

Enhanced corrosion resistance, surface hardness, and wear protection tailored to application conditions. - Detail Conformity:

Thin metallic layers that accurately follow part geometry, edges, and fine details without excessive build-up.

Unlike thick-film coatings, electroplating forms a controlled metallic layer that enhances surface properties while maintaining dimensional accuracy, making it suitable for tolerance-sensitive and performance-driven die cast parts.

Key Technical Control & Quality Focus:

- Plating Thickness: Precisely controlled to meet functional and dimensional requirements

- Adhesion Testing: Verified through standardized adhesion and integrity checks

- Surface Consistency: Uniform thickness and coverage monitored per batch

- Process Compliance: Plating systems aligned with applicable RoHS and REACH requirements

By performing plating within our manufacturing system, we align casting quality, surface preparation, and electroplating control as one integrated process—delivering stable, repeatable plated finishes without reliance on disconnected third-party operations.

Design Guidelines for Plated Die Cast Parts

Die casting plating delivers the most reliable results when plating requirements are considered during the part design stage, rather than treated as a corrective surface process later. Because electroplated layers are thin and highly sensitive to surface condition and geometry, substrate design has a direct impact on adhesion, thickness uniformity, and long-term performance.

To achieve stable plating quality on die cast parts, we recommend:

- Avoiding deep blind holes, enclosed cavities, or narrow recesses where plating solution flow and current distribution are difficult to control

- Designing smooth transitions and generous radii instead of sharp edges to prevent excessive thickness buildup or weak adhesion areas

- Clearly defining functional and non-functional surfaces, especially where masking or controlled plating areas are required

- Maintaining consistent surface conditions across plated areas to support uniform current density and coating growth

By aligning die casting design with electroplating behavior, plated die cast parts achieve stronger adhesion, more consistent thickness, and reliable surface performance across production batches—without relying on corrective processing or post-plating rework.

While electroplating provides functional and decorative metallic surfaces, certain die cast part features require careful evaluation:

- Precision bearing seats or datum surfaces where plating thickness must be tightly controlled to maintain dimensional accuracy

- Threaded features or fine tolerances where metal build-up may affect fit, torque, or assembly performance

- Deep internal cavities or enclosed areas where solution flow, current distribution, and rinsing are difficult to control

In these situations, selective masking, controlled local plating, secondary machining, or alternative surface treatments may deliver more stable and predictable results than full-part electroplating.

We provide DFM-driven engineering feedback specifically for die casting projects at the quotation stage, with a strong focus on plating feasibility and surface performance requirements.

Our engineers evaluate part geometry, functional surfaces, tolerance sensitivity, and masking or selective plating complexity to determine whether full plating, localized plating, or alternative surface treatments will deliver the most stable and reliable results — before production begins.

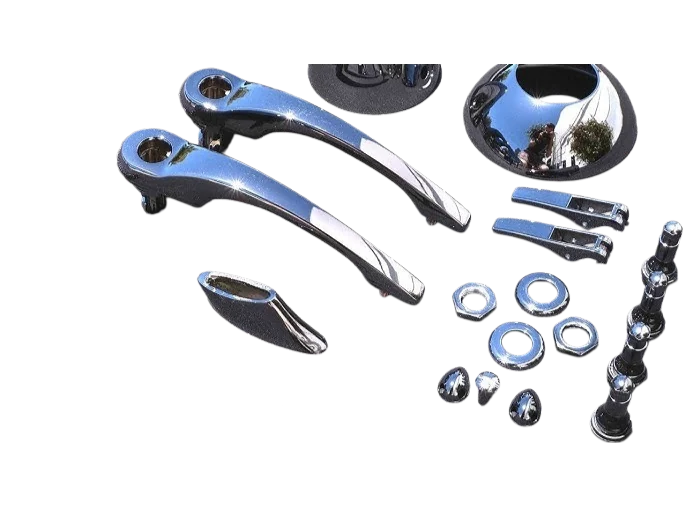

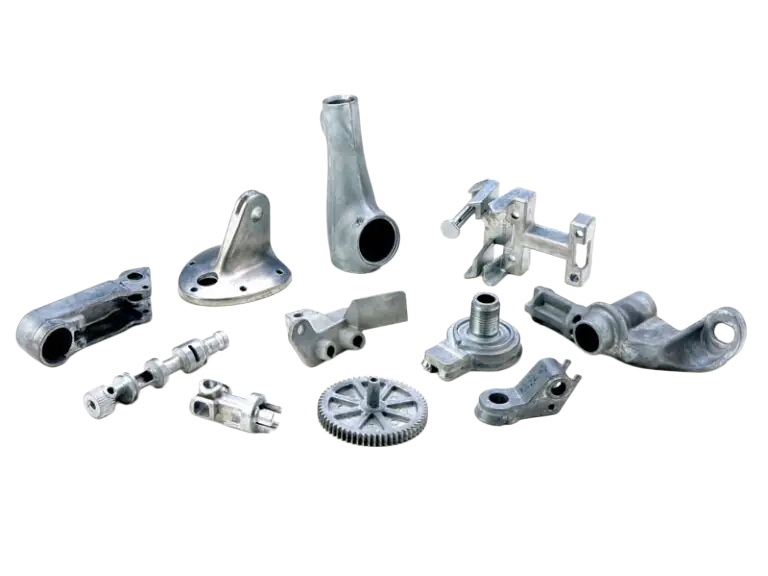

Plating for Typical Applications of Die Cast Parts

Automotive Functional & Decorative Components

– Trim elements, brackets, and housings requiring corrosion resistance, wear durability, and stable metallic appearance over long service life.

Automotive & Industrial Fastening Parts

– Zinc die cast components where plated surfaces enhance corrosion resistance while maintaining dimensional accuracy.

Industrial Mechanical Components

– Die cast parts exposed to friction, handling, or corrosive environments, where plating improves surface hardness and durability.

Electrical & Connector Housings

– Components requiring reliable conductivity, corrosion protection, or controlled surface performance in assembly and operation.

Decorative Metal Hardware

– Handles, fittings, and visible metal parts where electroplating delivers a refined metallic finish combined with functional protection.

Consumer Electronics & Hardware Parts

– Structural or visible components where thin metallic layers provide controlled thickness, conductivity, or premium surface appearance.

Our 6 Quality Controls for Plated Die Cast Parts

Die casting plating quality is ensured through systematic inspection and process control, focusing on adhesion, coating thickness, and long-term surface performance rather than purely cosmetic appearance.

- Incoming Die Cast Surface Inspection

Each batch is checked for surface cleanliness, porosity, and substrate condition to prevent adhesion issues or plating defects. - Surface Preparation Verification

Pretreatment, activation, and underlayer processes are monitored to ensure the substrate is fully ready for plating. - In-Process Plating Control

Electroplating parameters are tracked for uniform coverage, consistent thickness, and conformity to complex geometries. - Adhesion and Layer Integrity Testing

Standardized tests confirm proper bonding, absence of peeling or blistering, and consistent plating quality across the part. - Functional and Surface Performance Evaluation

Inspections verify coating thickness, hardness, corrosion resistance, and metallic finish according to design requirements. - Batch Traceability and Consistency Management

Each production batch is monitored to ensure repeatable plating results from prototype through full-scale manufacturing.

Why Die Casting Plating Can Be Challenging — How We Control It

Plating defects often originate from the die casting itself rather than the plating process. Surface porosity, alloy composition, and complex geometries can affect adhesion, thickness uniformity, and long-term performance. As an integrated die casting and plating manufacturer, we address these risks from casting through surface preparation and plating, rather than correcting problems after they appear.

| What Customers Usually See | Why This Happens on Die Cast Parts | How We Prevent It in Production |

|---|---|---|

| Uneven Coating or Thin Spots | Surface micro-porosity or irregular geometry affects current distribution | Controlled surface pretreatment, porosity-aware cleaning, and optimized plating parameters for uniform deposition |

| Excess Build-Up or Overplating in Recesses | Complex shapes or sharp corners disrupt plating flow | Optimized current density, selective masking, and engineering guidance on geometry |

| Inconsistent Appearance Between Batches | Variations in substrate condition, plating bath chemistry, or process timing | Standardized bath control, in-house surface preparation, and batch-monitored plating cycles |

| Localized Adhesion Issues | Residual oils, release agents, or uneven activation | Degreasing, chemical activation, and inspection prior to plating |

| Edge or Corner Irregularities | Sharp or complex edges create uneven layer thickness | Design guidance on edge radii, localized plating control, and masking of critical areas |

| Surface Contamination Marks | Dust, particles, or handling residue | Cleanroom handling, inspection, and proper surface preparation before plating |

Die Casting Plating vs Powder Coating and Anodizing

Die casting plating offers unique advantages for parts where functional metallic surfaces, corrosion resistance, and precise thickness control are priorities. While powder coating and anodizing provide protective or decorative surfaces, plating excels in adhesion, thin uniform layers, and performance-critical applications.

| Feature / Consideration | Die Casting Plating | Powder Coating | Anodizing |

|---|---|---|---|

| Compatibility with Die Cast Materials | Works on aluminum and zinc; suitable for functional and decorative finishes | Excellent for aluminum, zinc, magnesium; optimized for industrial durability | Mainly aluminum; sensitive to porosity |

| Coating Thickness | Thin, precisely controlled metallic layer | Thick, protective polymer layer | Thin oxide layer |

| Edge & Corner Coverage | Excellent; conforms closely to complex geometries | Strong, full coverage | Limited; sharp edges may be undercoated |

| Functional & Cosmetic Consistency | High adhesion, uniform thickness, and metallic finish | Consistent color and surface texture; less flexible for functional customization | Limited color options; metallic sheen only |

| Geometry Compatibility | Conforms to fine details, recesses, and critical functional surfaces | Excellent for external shapes | Difficult on intricate shapes |

| Production Volume Suitability | Low to high; suitable for prototypes, small batches, and mass production | Medium to high | Low to medium |

| Design & Performance Flexibility | Supports multi-layer systems, selective plating, and functional surface requirements | Moderate; mainly uniform finishes | Limited to natural anodized appearance |

Key Takeaway

For die cast parts where surface performance, controlled thickness, and metallic functionality are critical, die casting plating is the ideal choice—especially for prototypes, selective plating, or functional and decorative components. Powder coating provides durable coverage for high-volume industrial parts, while anodizing is best suited for selective aluminum components needing corrosion resistance or a natural metallic finish.

Why Customers Choose IEC Mould for Their Plated Die Cast Parts

At IEC Mould, we deliver reliable, high-quality plated die cast components engineered for functional performance and precision surface finishes.

- Design-focused production: Our integrated process ensures each part achieves uniform metallic coating, controlled thickness, and consistent surface performance—even for prototypes or low-volume runs.

- Complete in-house control: From die casting and surface preparation to electroplating, every step is closely monitored to maintain adhesion, uniformity, and long-term durability.

- Flexible and customized finishes: We support selective plating, multi-layer systems, and tailored metallic appearances to meet your functional and design requirements.

- Proven global experience: Our die casting and plating expertise has successfully delivered reliable, high-performance plated components for international clients across automotive, electronics, industrial, and decorative applications.

Start Your Die Casting Plating Project

Contact our engineering team to discuss your application, part design, and plating requirements.

Our experts work with you to ensure precise metallic finishes, uniform coating thickness, and reliable surface performance—helping your die cast parts meet functional and aesthetic expectations without unexpected issues.