Magnesium die casting manufacturers are at the forefront of lightweight innovation across industries. The global magnesium die casting market is experiencing significant growth, driven by increasing demand for lightweight components across automotive, aerospace, and electronics industries. Magnesium alloys offer a 33% weight reduction compared to aluminum, making them ideal for applications where weight savings and fuel efficiency are critical. This comprehensive analysis explores the leading manufacturers, emerging technologies, and regional market trends, providing valuable insights for businesses seeking reliable magnesium die casting suppliers.

Why Magnesium Die Casting is Gaining Global Traction

Magnesium die casting has become a cornerstone of modern manufacturing, particularly in sectors prioritizing weight reduction and sustainability. The process involves injecting molten magnesium into precision molds under high pressure, producing components with exceptional strength-to-weight ratios, excellent dimensional accuracy, and superior surface finishes. As industries worldwide strive for greater efficiency and reduced environmental impact, magnesium die casting offers a compelling solution that balances performance with economic viability.

Global Market Overview and Growth Projections (2024–2032)

The global market for automotive parts, magnesium die-cast, continues to expand rapidly. According to industry research, the market was valued at millions of USD in 2024 and is projected to maintain a substantial compound annual growth rate (CAGR) through 2032. China represents a significant portion of both production and consumption, accounting for approximately 36.49% of the global market share in 2023, with expectations to reach 41.43% by 2030. Other key regions include North America and Europe, where technological advancements and stringent quality standards drive innovation.

Top 10 Global Magnesium Die Casting Manufacturers and Suppliers

Meridian Lightweight Technologies

As a global leader in lightweighting solutions, Meridian specializes in magnesium die casting for automotive applications. The company’s expertise in producing large, thin-walled components makes it a preferred supplier for major automotive manufacturers seeking to reduce vehicle weight without compromising safety or performance.

IEC Mould is a leading Chinese die casting manufacturer with over 20 years of experience, specializing in custom aluminum, zinc, and magnesium alloy components. The company provides a complete one-stop service from design and prototyping to precision machining, surface treatment, and assembly.

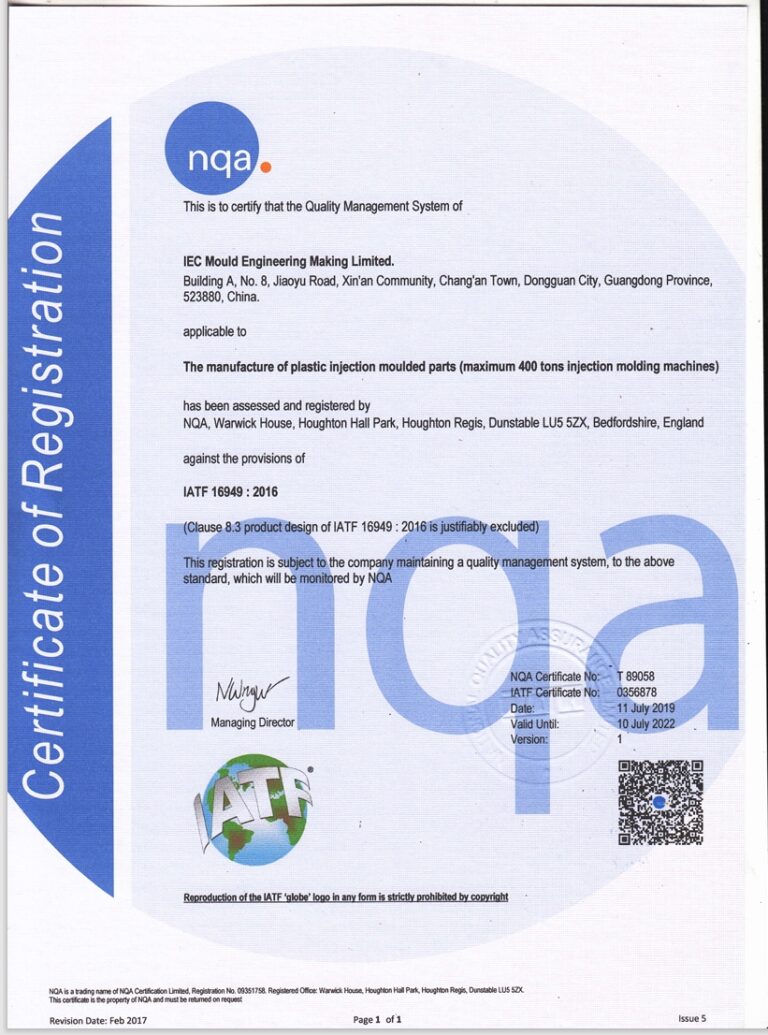

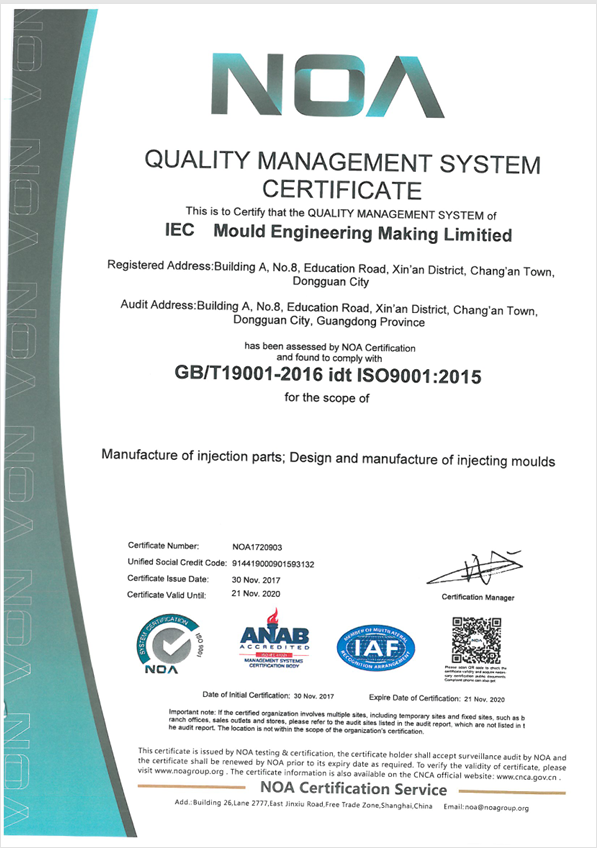

Certified to ISO 9001 and IATF 16949 standards, it ensures high quality through advanced processes like AI-powered X-ray inspection, guaranteeing tight tolerances and low defect rates. With a large library of pre-certified molds and high-volume production capability, IEC Mould serves global clients across automotive, electronics, and consumer industries, emphasizing fast delivery, cost efficiency, and reliable supply chain solutions.

Georg Fischer

With a strong presence across Europe and North America, Georg Fischer combines decades of experience with advanced manufacturing technologies. The company’s magnesium die casting division focuses on high-pressure applications for automotive and industrial sectors, maintaining rigorous quality standards and certifications.

Handtmann Group

This German manufacturer is recognized for its precision engineering and innovative die-casting technologies, producing high-quality magnesium components for the automotive and engineering sectors.

Ryobi Group

Ryobi is a global force in die casting with diversified capabilities across multiple materials, including magnesium. The company’s vertical integration allows it to deliver cost-effective solutions for high-volume production.

Shiloh Industries

Shiloh offers a multi-product approach that includes various lightweighting technologies, such as advanced magnesium die casting solutions. The company focuses on innovation and sustainability in its manufacturing processes.

DGS Druckguss Systeme AG

This company specializes in pressure die casting technology and is a noted supplier of magnesium components for commercial vehicle manufacturers.

Gibbs Die Casting

With facilities in North America and Asia, Gibbs provides comprehensive magnesium die casting services backed by decades of industry experience in both conventional and specialized processes.

Sundaram Clayton Limited (SCL)

Sundaram Clayton Limited (SCL) is one of the largest auto components manufacturing and distribution groups in India. SCL has developed specialized capabilities in magnesium die casting for automotive applications and is a trusted supplier to leading vehicle manufacturers.

Foryou Industries Co., Ltd

This Chinese manufacturer has rapidly expanded its magnesium die casting capabilities to meet growing domestic and international demand. The company’s competitive positioning reflects China’s increasing dominance in the global magnesium die casting market.

Key Application Areas and Industry Trends

Automotive Industry Dominance

The automotive sector remains the largest consumer of magnesium die-cast components, with applications spanning interior systems, engine and powertrain components, front-end and rear-end structures, and steering mechanisms. The push for vehicle lightweighting to improve fuel efficiency and reduce emissions continues to drive innovation in this segment.

Emerging Applications

- Aerospace: For aircraft components where weight reduction is critical

- Electronics: Enabling thinner walls and tighter tolerances for device housings

- Industrial equipment: Providing durability and weight savings for machinery components

Technological Advancements

- Vacuum die casting for improved mechanical properties

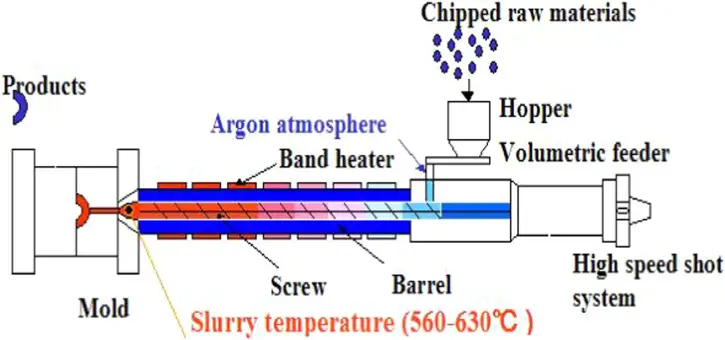

- Thixomolding for enhanced precision and reduced porosity

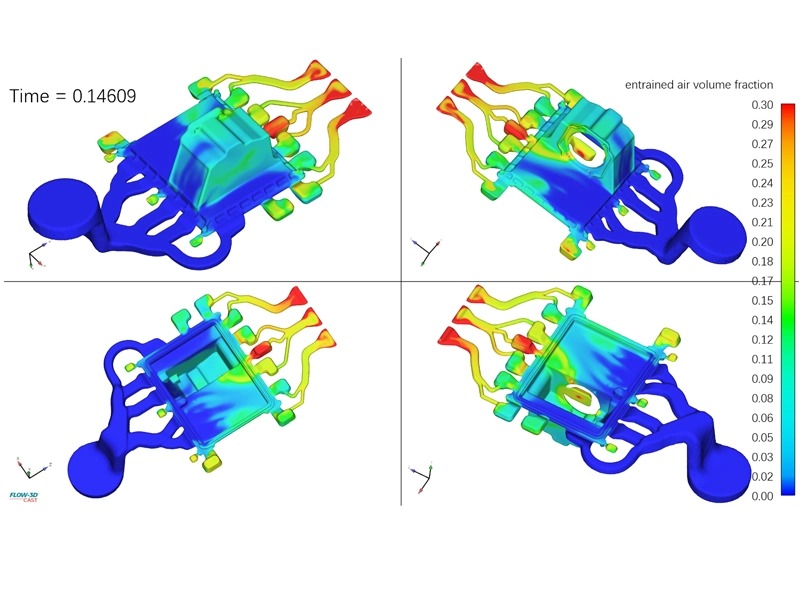

- Integrated quality control systems ensure consistent results

How to Select the Right Magnesium Die Casting Partner

Choosing an appropriate supplier requires careful consideration of several factors:

Technical Capabilities Assessment

- Equipment portfolio and technological sophistication

- Quality certifications (ISO 9001, IATF 16949, etc.)

- Material expertise and alloy development capabilities

- Production capacity and scalability

Quality and Compliance Standards

Reputable manufacturers maintain stringent quality control measures throughout the production process, from raw material inspection to final product verification. Certifications demonstrate adherence to international standards and industry-specific requirements.

Geographic and Supply Chain Considerations

Proximity to your operations or end markets can significantly impact logistics costs and lead times. Additionally, assess suppliers’ supply chain resilience and raw material sourcing strategies.

Why Choose Our Magnesium Die Casting Services?

At IEC MOULD, we have established ourselves as a reliable partner for precision magnesium die casting components. Our services stand out through:

Advanced Manufacturing Capabilities

We utilize state-of-the-art die casting equipment and implement rigorous quality control measures to ensure consistent, high-quality results for every project.

Comprehensive Service Portfolio

- Product design and engineering support

- Tooling design and fabrication

- Precision die casting production

- Secondary operations and finishing

- Quality assurance and testing

Global Compliance and Certification

We maintain internationally recognized quality management certifications, ensuring our processes and products meet the highest industry standards for performance and reliability.

Customer-Centric Approach

We collaborate closely with clients to understand their specific requirements, offering flexible production solutions and responsive technical support throughout the project lifecycle.

Future Outlook: Magnesium Die Casting Market Trends (2026–2030)

Lightweighting Imperative

Regional Market Evolution

Material and Process Innovation

Conclusion

The global magnesium die casting market presents significant opportunities for businesses seeking to leverage lightweighting advantages across various industries. By partnering with established manufacturers that demonstrate technical expertise, quality commitment, and innovation capabilities, companies can effectively incorporate magnesium components into their products. As market dynamics continue to evolve, staying informed about industry trends and emerging technologies will be crucial for maintaining competitive advantage.