The magnesium die casting market is experiencing significant growth, driven by the increasing demand for lightweight, high-strength components in the automotive, aerospace, and electronics industries. Magnesium, the lightest of all structural metals, offers an exceptional strength-to-weight ratio and excellent durability. However, its high reactivity and narrow processing window make it particularly susceptible to specific magnesium die casting defects. Understanding these flaws and the intricacies of the magnesium die casting process itself is the first step toward elimination. This comprehensive guide delves into the most common defects, their root causes, and practical solutions to help you achieve flawless production.

Why Magnesium Poses Unique Casting Challenges

Before diving into specific issues, it’s crucial to understand what makes magnesium distinct from aluminum or zinc. Its unique properties directly influence the defects you may encounter:

High Reactivity

Magnesium oxidizes rapidly when molten, requiring protective atmospheres (like SF6 or SO2 mixes) to prevent burning. This reactivity can lead to inclusions and oxidation defects.

Narrow Processing Window

Critical Temperature Control Ranges

Melt Temperature

680 - 710 °C

Overheat Zone > 720°C

Die Temperature

200 - 260 °C

Up to 280°C for thin walls

Raw Material Drying

120 - 150 °C

(2-4 hours)

Excellent Fluidity

While beneficial for filling thin walls, this can also lead to flash if the process isn’t tightly controlled.

Common Magnesium Die Casting Defects and Solutions

Here is a detailed breakdown of the most common Magnesium Die Casting Defects and how to solve them.

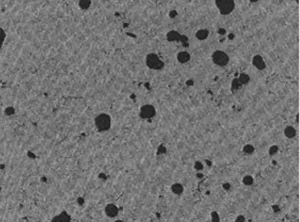

Porosity: The Most Troublesome Defect

Porosity is arguably the most challenging of all Magnesium Die Casting Defects, presenting as small, round (gas) or irregular (shrinkage) voids within the casting. It severely compromises mechanical strength, pressure tightness, and corrosion resistance.

- Gas Porosity: Caused by trapped air from turbulent filling, hydrogen from moisture in raw materials (e.g., damp ingots or flux), or gases from excessive lubricant.

- Shrinkage Porosity: Results from inadequate feeding of molten metal to compensate for volumetric shrinkage during solidification, often in thick sections.

- Strict Raw Material Control: Dry magnesium ingots and returns at 120-150°C for 2-4 hours to eliminate moisture. Store fluxes in a dry environment and preheat before use.

- Optimized Degassing: Use argon or nitrogen at a flow rate of 0.5-1.5 L/min for a minimum of 15 minutes. Consider secondary degassing for high-integrity castings.

- Enhanced Mold Venting: Increase exhaust channels at the end of fill and dead zones. Recommended vent dimensions: 8-12 mm wide, 0.03-0.05 mm high.

- Precise Process Parameters: Reduce injection speed to promote laminar flow; increase die temperature to 180-250°C to extend solidification time for gas escape; strictly control melt temperature to avoid overheating (do not exceed 720°C).

Cold Shuts & Misruns: A Critical Category of Magnesium Die Casting Defects

Cold shuts appear as visible lines or seams on the casting surface where metal streams fail to fuse. Misruns result in incomplete filling of the mold cavity. Both are critical defects that destroy part integrity.

Root Causes: Low melt or die temperature, slow injection speed, and poor gating design that causes premature solidification.

- Temperature Management: Increase melt temperature to 680-710°C for improved fluidity. Raise die temperature to 200-260°C (up to 280°C for complex thin-wall parts) using mold temperature controllers for uniformity.

- Optimized Injection Parameters: Increase injection speed to 1-3 m/s to shorten fill time. Ensure sufficient injection pressure (80-120 MPa) to push metal into all cavity sections.

- Improved Gating Design: Increase runner cross-sectional area to reduce flow resistance. Use multiple gates for complex parts to ensure balanced filling.

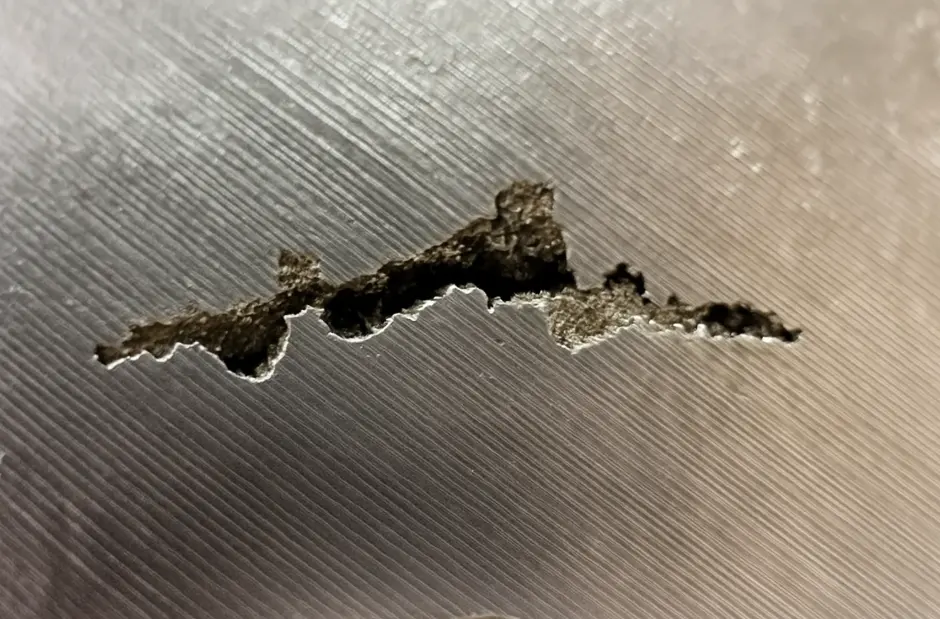

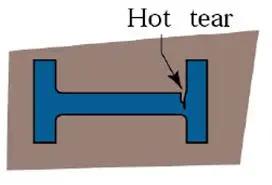

Hot Tearing: Stress-Induced Magnesium Die Casting Defects

Hot tears are intergranular cracks that occur as the casting solidifies and contracts, often in areas with changing wall thickness. They are a critical failure point.

Root Causes: Restricted shrinkage due to mold design, high die temperature gradients, and alloy compositions with high hot tearing sensitivity.

- Design for Manufacturability (DFM): Modify product design to avoid sharp corners and ensure uniform wall thickness. Add ribs or process holes to reduce localized thick sections.

- Controlled Cooling: Optimize the mold cooling system. Install cooling channels in thick sections to promote uniform solidification and reduce thermal stress. Control water temperature at 30-50°C.

- Alloy Selection: Choose alloys with lower susceptibility to hot tearing, such as AZ91D, compared to others like AM60B.

- Process Adjustment: Implement a sufficient holding pressure phase (60-80% of injection pressure for 3-8 seconds) to feed the shrinkage during solidification.

Soldering & Surface Defects

Soldering occurs when molten magnesium alloy welds to the die steel, leaving a rough, torn surface. Other defects include stains (from oxidation) and flashes (thin excess metal).

Root Causes: Overheated metal, improperly maintained die surfaces, insufficient or incorrect die lubricant, and magnesium’s high reactivity.

- Robust Melt Protection: Use flux or inert gas (Argon) protection during melting to prevent oxidation and contamination.

- Die Surface Maintenance: Polish die surfaces regularly to a roughness of Ra ≤ 0.8 μm. Apply protective coatings (e.g., nitriding) to enhance soldering resistance.

- Precise Lubrication: Apply high-quality, magnesium-specific die lubricants sparingly and consistently.

- Control Mold Fit: Ensure parting line fit and control core/cavity gaps within 0.02-0.03 mm to prevent flash. Adjust clamping force to eliminate gaps.

| Solution | Porosity | Shrinkage | Cold Shut | Hot Tear | Soldering |

|---|---|---|---|---|---|

| Vacuum Die Casting | ★★★★★ | ★★☆☆☆ | ★★★☆☆ | ☆☆☆☆☆ | ☆☆☆☆☆ |

| Optimized Mold Venting | ★★★★★ | ☆☆☆☆☆ | ★★★☆☆ | ☆☆☆☆☆ | ☆☆☆☆☆ |

| Precise Temperature Control | ★★★★☆ | ★★★★☆ | ★★★★★ | ★★★★★ | ★★★★☆ |

| Optimized Injection Speed/Pressure | ★★★☆☆ | ★★★★★ | ★★★★★ | ★★★☆☆ | ☆☆☆☆☆ |

| High-Quality Die Lubricant | ★★☆☆☆ | ☆☆☆☆☆ | ☆☆☆☆☆ | ☆☆☆☆☆ | ★★★★★ |

| Regular Die Maintenance | ★★★☆☆ | ☆☆☆☆☆ | ☆☆☆☆☆ | ☆☆☆☆☆ | ★★★★★ |

Legend: More stars (★) = greater effectiveness.

Proactive Prevention: Best Practices to Minimize Magnesium Die Casting Defects

Systematic Process Control

Rigorously monitor and document all parameters of the magnesium die casting process (temperatures, pressures, speeds). Use real-time monitoring systems for consistency.

Preventive Die Maintenance

Establish a regular schedule for die cleaning, inspection, and repair to prevent issues like soldering and flash at their source.

Quality at the Source

Use high-purity alloys and implement strict material handling procedures to minimize contamination.

FAQ

What is the most common defect in magnesium die casting?

Porosity stands out as the most common and challenging of all magnesium die casting defects, primarily due to magnesium’s high susceptibility to gas absorption and shrinkage during solidification.

How can I prevent soldering on my magnesium castings?

Focus on three areas: 1) Use a high-quality, magnesium-specific die lubricant; 2) Maintain a polished die surface (Ra ≤ 0.8 μm) and consider protective coatings; 3) Avoid overheating the melt and die.

Why is vacuum die casting highly recommended for magnesium?

Vacuum die casting actively removes air from the mold cavity before and during injection, which is the most effective method for eliminating gas porosity, magnesium’s most common defect.

What is the ideal die temperature range for magnesium?

A typical range is 200-260°C. For complex or thin-walled parts, it may be necessary to increase this to 280°C to prevent cold shuts and misruns.

Conclusion

Mastering the prevention of magnesium die casting defects requires a deep understanding of the root causes and a disciplined approach to process control. By implementing the data-driven solutions outlined above—from precise temperature control to optimized gating and systematic maintenance—you can significantly reduce defect rates, lower costs, and produce high-integrity magnesium components that meet the most demanding applications.

Struggling with casting defects? Contact our experts today to schedule a consultation and receive a quote for your next project.