We’re covering everything you need to know about high pressure die casting, including step-by-step process breakdowns, common defects and solutions, sustainability trends, and answers to the most Googled questions about HPDC manufacturing. This guide will help you make an informed decision if this technique fits your next project.

What Is High Pressure Die Casting (HPDC)?

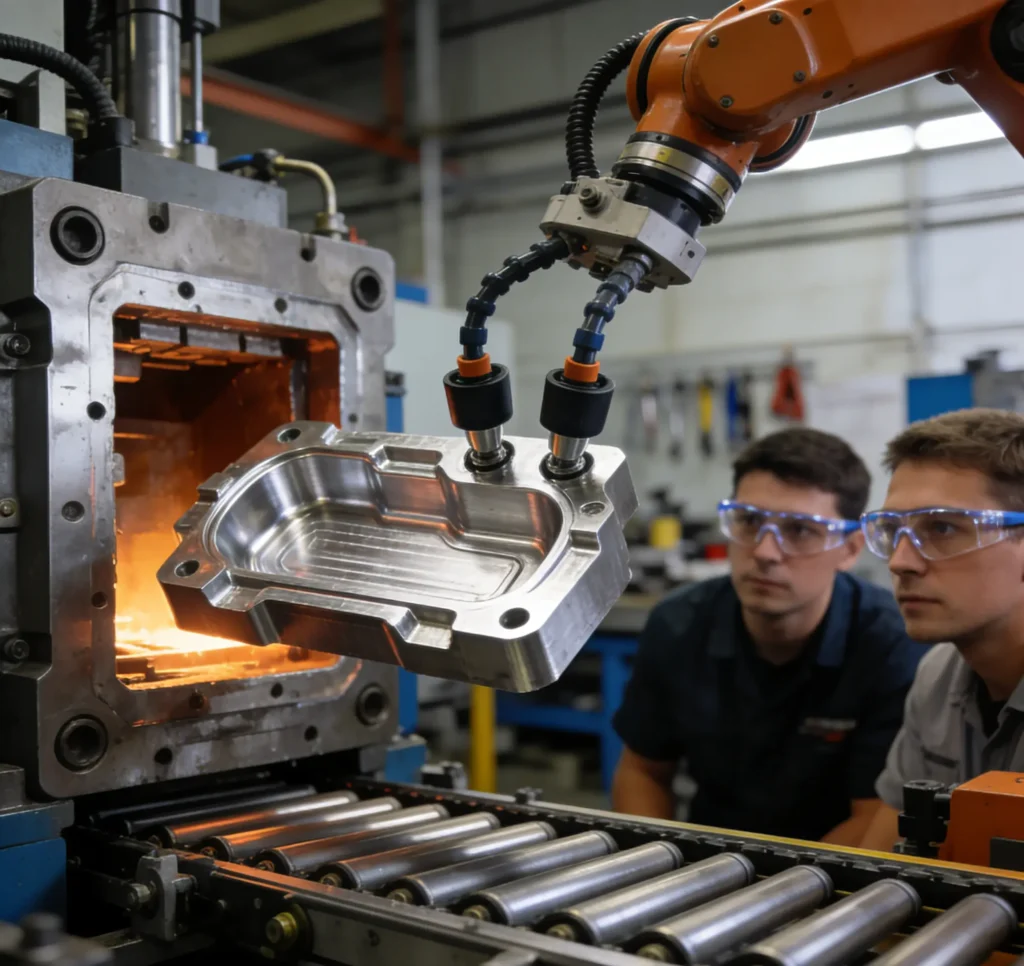

High pressure die casting (HPDC) is a metal casting process where molten metal—such as aluminum, zinc, or magnesium—is forced into a steel mold (called a die) at high pressure (usually 10–200 MPa) and speed. Once the metal cools and hardens, the die opens to eject the finished HPDC part.

Real-World Applications of High Pressure Die Casting

- Automotive components: Car manufacturers rely heavily on high pressure die casting for parts like aluminum engine blocks, transmission housings, and brake calipers. For example, Tesla uses HPDC to produce lightweight magnesium alloy chassis parts, as the process ensures tight tolerances (critical for proper fit) and fast production to meet high vehicle demand.

- Consumer electronics: Brands like Apple use zinc HPDC for iPhone frame parts. The process creates thin, durable walls (as thin as 0.5mm) with smooth surfaces, reducing post-finishing time for sleek device exteriors.

- Industrial hardware: Heavy equipment makers (like Caterpillar) use HPDC for hydraulic valve bodies. The high pressure fills complex internal channels—vital for fluid flow—while producing dense, pressure-resistant parts that withstand tough working conditions.

What Are the Main Advantages of High Pressure Die Casting?

| HPDC Advantage | Key Details |

|---|---|

| High precision & tight tolerances | Parts have smooth surfaces, eliminating post-finishing for many applications |

| Fast cycle times | Hundreds/thousands of parts per hour; ideal for large-scale manufacturing |

| Complex part design | Creates detailed shapes (thin walls, fine details) that other casting methods can’t |

| Strong, durable parts | Molten metal fills molds under pressure, resulting in dense, high-strength components |

What Pressure Is Used in HPDC Casting?

Is HPDC Right for Your Project?

HPDC Metal Materials: Which Is Right for Your Part?

Metal | Typical Pressure (MPa) | Key Benefits | Common Applications | Limitations |

|---|---|---|---|---|

Aluminum Alloys | 40–120 | Lightweight, high strength-to-weight ratio, corrosion-resistant | Automotive engine blocks, electronics housings | Higher tooling wear; not good for very high-temperature parts |

Zinc Alloys | 10–50 | Low melting point (fast cycle times), excellent detail replication | Consumer electronics frames, hardware hinges | Lower strength; heavier than aluminum |

Magnesium Alloys | 60–150 | Ultra-lightweight, high rigidity | EV chassis parts, aerospace components | More flammable (needs special safety measures) |

HPDC Project Cost: Key Factors to Budget For

| Cost Category | Details & Pricing |

|---|---|

| Die Tooling Costs | Custom steel dies: $10,000–$100,000+ (varies by part complexity, size, die material) |

| Material Costs | Price per kg: Zinc ($2–$4); Aluminum ($3–$6); Magnesium ($8–$12) (total = weight × volume) |

| Production Costs | Labor/machine/energy: $0.10–$1.00 per part (lower per unit at higher volumes) |

| Post-Processing Costs | Optional (machining/painting/plating): adds 5–20% to total part cost (depends on finish) |

Cost Comparison: HPDC vs. Sand Casting vs. Injection Molding

HPDC VS. Sand Casting:

Sand casting has lower upfront tooling costs ($500–$5,000 for molds, vs. $10k–$100k for HPDC dies), making it better for small-batch (10–1,000 units) or prototype production. However, HPDC has much lower per-unit costs for high volumes (10,000+ units)—sand casting’s per-part cost ($2–$20) is 2–20x higher than HPDC’s ($0.10–$1.00) at scale. HPDC also avoids sand casting’s higher post-processing costs (e.g., sand residue cleanup, surface finishing).

HPDC vs. Injection Molding:

Injection molding (for plastics) has similar high upfront tooling costs ($5k–$50k+) to HPDC but lower material costs ($1–$5 per kg for plastics, vs. $2–$12 for HPDC metals). Great for plastic parts, but HPDC is better for metal components—it offers unmatched strength and durability. For high-volume metal parts, HPDC’s per-unit production costs are comparable to injection molding’s, but material costs are higher.

Key takeaway: High pressure die casting is cost-effective for high-volume metal parts. Sand casting suits small batches/prototypes, and injection molding is for plastics. Choose the right process by matching your production volume and material needs to HPDC’s strengths.